Inconel 600 Forged Fittings Manufacturer

Home / Inconel Forged Fittings / Inconel 600 Forged Fittings

Inconel 600 is a nickel-chromium alloy that is widely used in high-temperature applications. Inconel 600 forged fittings are made from this alloy using a forging process. Forging is a technique in which a metal is shaped by heating it & then applying force to the heated material. Inconel 600 forged fittings are highly heat-resistant and corrosion-resistant, making them ideal for harsh environments.

The benefits of Inconel 600 Forged Fittings are numerous. One of the main advantages is their excellent corrosion resistance also this makes them an excellent choice for use in environments where other materials might be prone to failure due to corrosion. Inconel Alloy 600 Forged Fittings have excellent strength, perfect for high-temperature applications where other metals might become weak and brittle.

Table Of content

- About Inconel 600 Forged Fittings

- Specification List of Inconel 600 Forged Fittings

- Equivalent Grades Of Inconel 600 Forged Fittings

- Manufacturing Standards of ASTM B564 Inconel 600 Forged Fittings

- Different Types of Inconel 600 Forged Fittings

- Available Stock of Inconel 600 Socketweld Forged Fittings

- Chemical Structure of Inconel 600 Forged Fittings

- Mechanical Properties of Inconel 600 Forged Fittings

- We Serve Application Industry

- We Export Inconel 600 Forged Fittings Across the Globe

- Domestic Supply Inconel 600 Forged Fittings

600 Inconel Forged Fittings find applications across different industries. Some of the common applications for these fittings include use in chemical processing, jet engines, aerospace & marine industries. Inconel Alloy 600 Forged Fittings are also commonly used in heat-treating furnaces, power generation plants, and other high-temperature applications.

UNS N06600 Forged Fittings are known for their exceptional properties. They have a high nickel content, which provides excellent corrosion resistance. In addition, they also have good resistance to oxidation and scaling at high temperatures. Inconel 2.4816 Forged Fittings include high thermal conductivity & low electrical resistivity, making them an excellent choice for electrical components and heat exchangers. The high-quality inconel products we provide at Global Steel include Inconel 601 Forged Fittings, Inconel 617 Forged Fittings and more.

Alloy 600 Forged Fittings are precision-engineered components crafted from the nickel-chromium alloy Inconel 600 through a specialized forging process. This alloy’s remarkable attributes, including exceptional resistance to high temperatures, corrosion & oxidation, make it an ideal choice for demanding applications in aerospace, chemical processing, and nuclear engineering. We provide an extensive range of products, such as Inconel Olets, Monel K500 Forged Fittings and many others.

Inconel 600 to controlled heating and mechanical pressure, the forging process enhances the fittings’ strength, durability & overall performance. ASTM B564 Inconel Alloy 600 Forged Fittings provide a reliable solution for critical systems that operate in extreme conditions, ensuring long-term integrity and optimal functionality.

What are the benefits of using Inconel 600 Forged Fittings?

Inconel 600 Forged Fittings offer remarkable high-temperature and corrosion resistance, making them suitable for extreme environments such as chemical processing, aerospace, and power generation. Their robust mechanical properties and resistance to oxidizing and reducing conditions contribute to their long-term performance and durability.

What are the temperature limits for Inconel 600 forged fittings?

Inconel 600 forged fittings are known for performing well across a wide temperature range. They can withstand temperatures as low as cryogenic levels and as high as approximately 2000°F (1093°C) while maintaining their mechanical properties and corrosion resistance.

What types of Inconel 600 Forged Fittings are available?

Inconel 600 Forged Fittings are available in various types, including elbows, tees, unions, couplings, and plugs. These fittings come in different shapes and sizes to facilitate precise connections and adapt to the requirements of specific piping systems.

Specification of Inconel 600 Forged Fittings

| Standards | ASTM B564/ ASME SB564 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Thread | NPT, BSPT, BSPP |

| Forged Fittings Test Certificates |

|

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Manufacturing Standards

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Inconel Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel Forged fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged fittings socket-weld and threaded. Socket Weld and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Inconel fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Different Types

Inconel 600 Forged Elbow

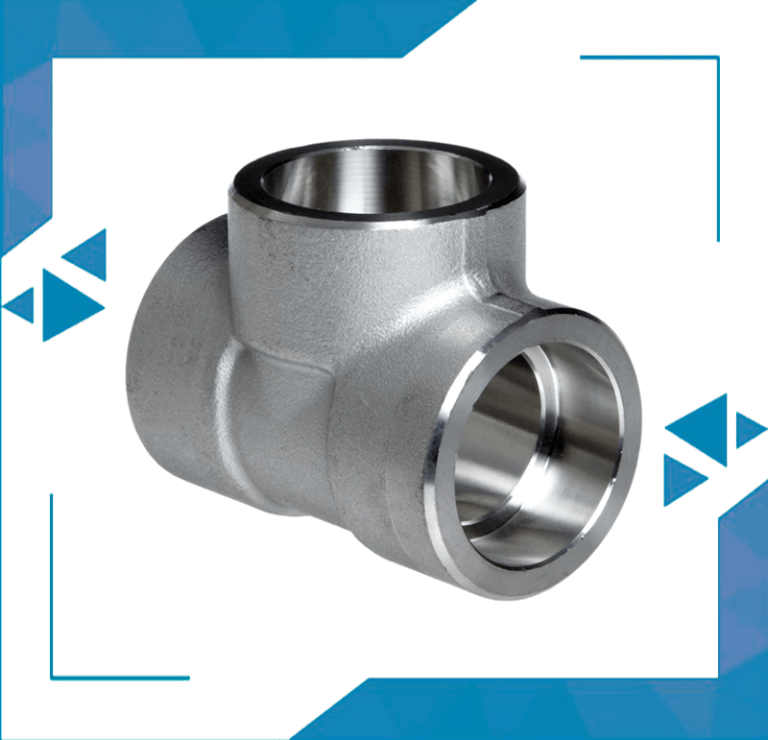

Inconel 600 Forged Tee

Inconel 600 Forged Cross

Inconel 600 Coupling

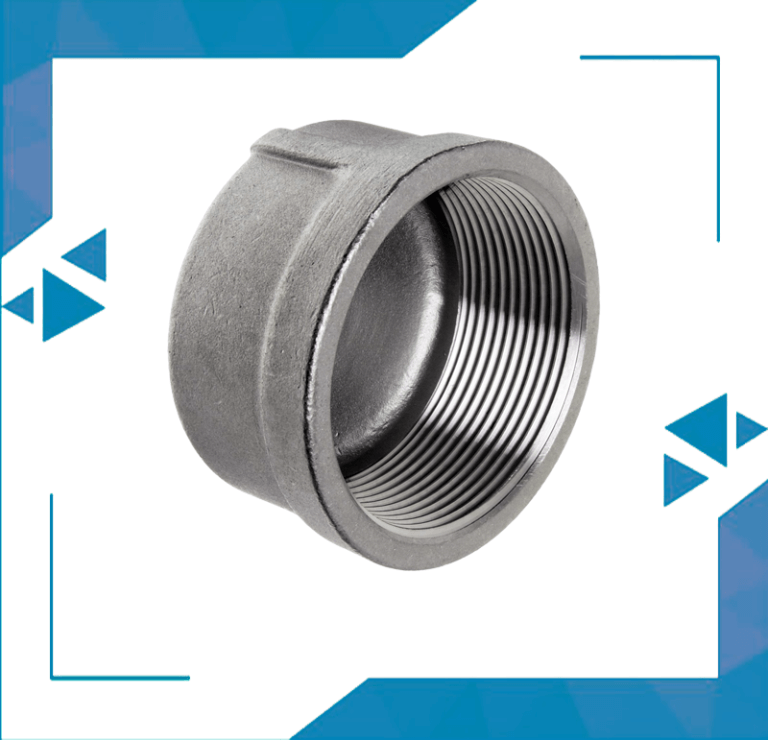

Inconel 600 Forged Cap

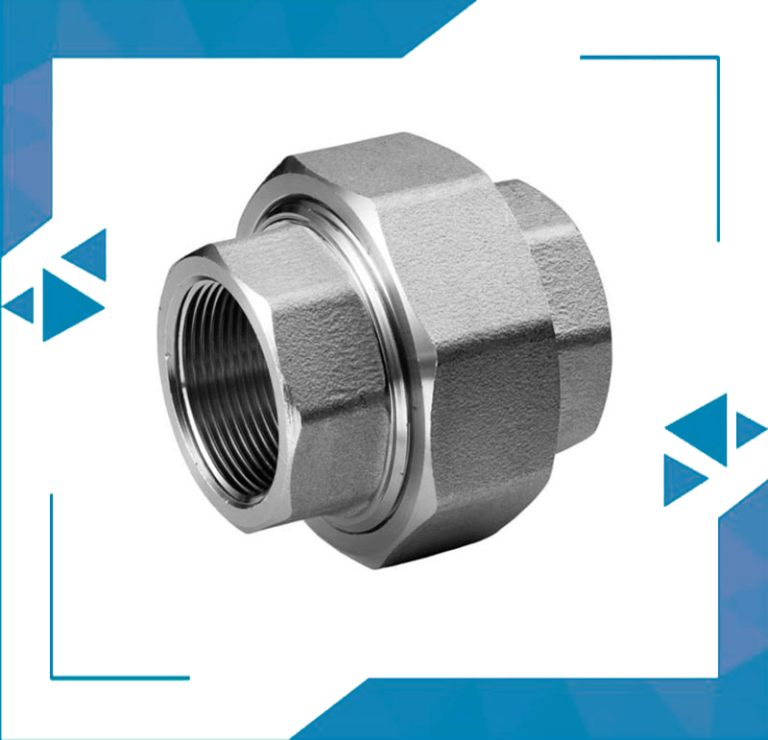

Inconel 600 Union

Contact us to get a quick quote for your requirement.

We offer These Inconel 600 Socketweld Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Type 600 Inconel Industrial Socketweld Fittings

- Grade 600 Inconel Forged Fittings

- UNS N06600 Socketweld Fittings

- Inconel® Alloy 600 NPT / BSP Threaded Fittings

- Alloy 600 Socketweld Cross

- Nickel Alloy 600 Forged Fittings

- Inconel Alloy 600 Forged Fittings

- 600 Inconel High Pressure Forged Pipe Fittings

- Inconel 2.4816 Socketweld Forged Fittings

- ASTM B564 600 Inconel Bushings

- Inconel 600 Forged Fittings

- UNS N06600 Inconel Threaded Round Head Plugs

- 600 Inconel Screwed Fittings

- ANSI B16.11 Inconel 600 Forged Caps

- ASME B16.11 Inconel Alloy 600 Forged Pipe Fittings

- Alloy 600 Forged Fittings

- Nickel Alloy 600 Scrwed Elbow

- Inconel Alloy Gr 600 Forged Fittings

- Inconel N06600 Socketweld Fittings

- Inconel 600 Forged Reducing Tee

- 600 Inconel Hex Head Bushings

- 600 Inconel Threaded Fittings

- Alloy 600 Socket Weld Elbow

- Inconel 600 45° Socket Weld Elbow

- Inconel Alloy 600 Forged Cross

- 600 Inconel 3000 LBS Threaded Fittings

- Inconel® Alloy 600 Screwed Bushing

- Alloy 2.4816 Socket Weld Reducing Tee

- Inconel 600 Socketweld Forged Nipple

- 600 Inconel Forged Cap

- Inconel 600 Hex Head Plug

- Inconel Grade 600 Screwed Fittings

- Alloy 600 Socketweld Forged Fittings

- Inconel 2.4816 3000LBS Socket Weld Fittings

- Inconel 600 2000 LBS Forged Fittings

- Inconel 600 Socket Weld Fittings

- 600 Inconel Alloy Forged Pipe Fittings

- Inconel 600 Reducing Insert

- Inconel 600 Full Couplings

- Inconel 600 ANSI/ ASME B16.11 Socketweld Fittings

- 600 Inconel® Alloy Socketweld Forged Fittings

- Alloy 600 Forged Street Elbow

- 600 Inconel Forged End Caps

- Inconel Alloy 600 90° Forged Elbow

- Inconel 600 Half Couplings

- Alloy 600 Forged Threaded Fittings

- Inconel 600 Socketweld Forged Fittings

- Alloy 600 Screwed Fittings

Chemical Structure

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

We Serve Application Industry

Application Industry

Socket weld Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004