Hastelloy Forged Fittings Manufacturer

Home / Hastelloy Forged Fittings

Global Steel is a leading manufacturer and supplier of Hastelloy forged Fittings. There are a wide range of Hastelloy forged fittings available and they can also be customized according to size, dimension and surface finish.

Hastelloy forged fittings are made of a corrosion-resistant nickel-molybdenum superalloy that is utilized in a variety of chemical processing, pollution control, and waste treatment applications. Hastelloy forged fittings can withstand a wide range of chemicals, including highly corrosive hydrochloric and sulfuric acids. They’re also one of the few materials that can tolerate wet chlorine gas, hypochlorite, and chlorine dioxide.

Table Of content

- About Hastelloy Forged Fittings

- Specification List of Hastelloy Forged Fittings

- Manufacturing Standards of ASTM B564 Hastelloy Forged Fittings

- Different Types of Hastelloy Forged Fittings

- Available Stock of Hastelloy Socketweld Forged Fittings

- We Serve Application Industry

- We Export Hastelloy Forged Fittings Across the Globe

- Domestic Supply Hastelloy Forged Fittings

Chemical processing industries use Hastelloy forged fittings because they offer good resistance to oxidizing and localized corrosion, including pitting and stress corrosion cracking. Hastelloy forged fittings are frequently utilized in chemical processing and other applications that demand excellent corrosion resistance due to their durability, thermal stability, and consistent performance.

Hastelloy forged fittings are utilized for a variety of welding applications, including weld overlay or cladding of steels, and once welded, they may be used in practically any chemical process in even the harshest environments. Hastelloy forged fittings are often more expensive than other corrosion-resistant metals like stainless steel, but it offers higher performance and mechanical stability, making them an excellent choice for highly corrosive situations.

Due to all its properties, Hastelloy forged fittings are used in a lot of industries such as Oil and gas, geothermal, mining, biomass, liquified natural gas, solar power, nuclear power, utilities, etc.

Hastelloy fittings can easily withstand extreme temperatures and environments and offer excellent performance. When these products are ready to ship, we pay close attention to the packaging. The products are packaged in a wooden case, pallet, or waterproof box to prevent rust and damage. Therefore, its excellent quality, strength, and durability make it an indispensable product in the industry.

Are Hastelloy Forged Fittings expensive?

Yes, Hastelloy forged fittings are generally considered more expensive than other types of fittings made from different materials. This is due to Hastelloy’s unique composition and high corrosion resistance properties, making it a preferred choice for use in harsh chemical and high-temperature environments. However, the exact cost of Hastelloy fittings can vary depending on size, pressure rating, and availability.

Can Hastelloy Forged Fittings be welded?

Yes, Hastelloy forged fittings can be welded with special welding techniques and filler metals for the high-temperature resistance and corrosion resistance properties of Hastelloy. Welding of Hastelloy fittings is typically done using Tungsten Inert Gas (TIG) or Gas Tungsten Arc Welding (GTAW) processes, which are preferred for their precision and control over the welding process. It’s essential to use the correct filler metal and carefully clean and prepare the surfaces to be welded to ensure a robust and high-quality weld joint.

In which sectors are Hastelloy Forged Fittings commonly use?

Hastelloy Forged Fittings are frequently used in various industries for outstanding resistance to corrosion and high-temperature conditions. Industries like petrochemical, pharmaceutical, chemical processing, aerospace, and defense sectors industries utilize this fitting since they are subjected to corrosive and caustic chemicals. They are also employed in the power generator sector where temperature and pressure resistance are needed.

Specification of Hastelloy Forged Fittings

| Standards | ASTM B564/ ASME SB564 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Thread | NPT, BSPT, BSPP |

| Forged Fittings Test Certificates |

|

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

Manufacturing Standards

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Hastelloy Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel Forged fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged fittings socket-weld and threaded. Socket Weld and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Hastelloy fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Different Types

Hastelloy Forged Elbow

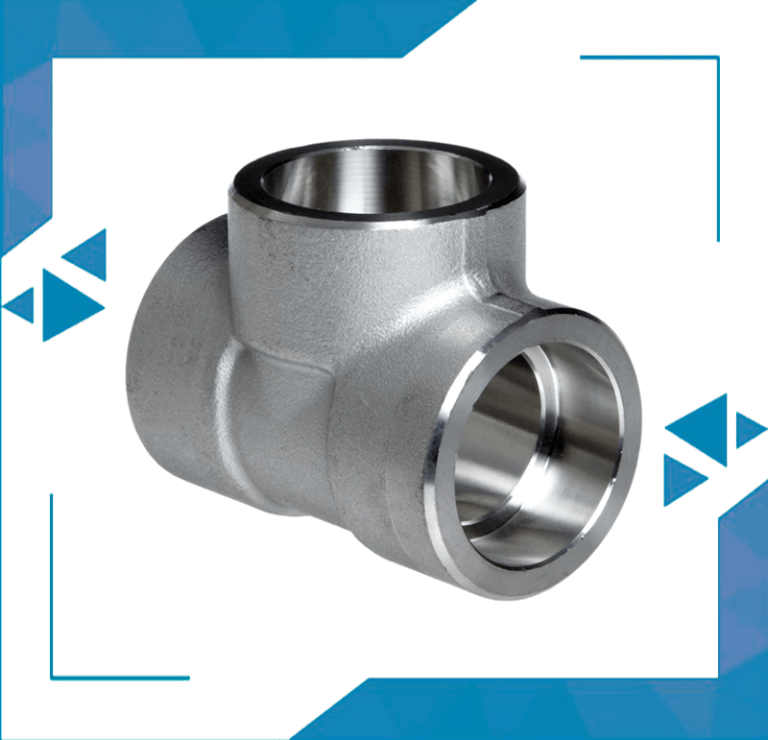

Hastelloy Forged Tee

Hastelloy Forged Cross

Hastelloy Coupling

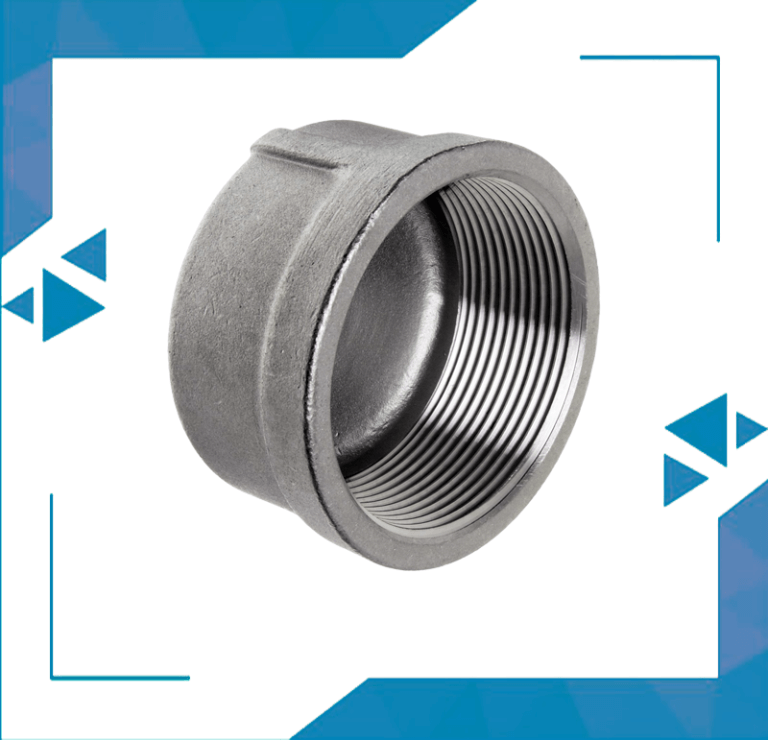

Hastelloy Forged Cap

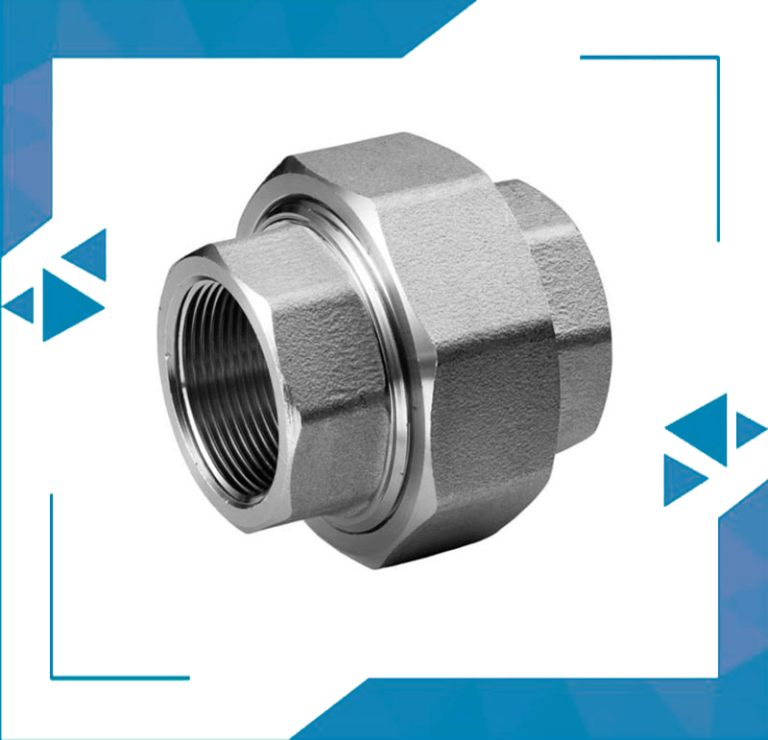

Hastelloy Union

Contact us to get a quick quote for your requirement.

We offer These Hastelloy Socketweld Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Hastelloy Alloy Forged Fitting

- Type Hastelloy Industrial Socketweld Fittings

- Hastelloy Socketweld Fittings

- Hastelloy Hex Head Bushings

- ANSI B16.11 Hastelloy Forged Caps

- Hastelloy 45° Socket Weld Elbow

- Hastelloy Forged Reducing Tee

- Hastelloy Threaded Round Head Plugs

- ASTM B564 Hastelloy Bushings

- Hastelloy Forged Fittings

- Hastelloy Hex Head Plug

- Hastelloy Socketweld Forged Nipple

- Hastelloy Reducing Insert

- Hastelloy Forged Street Elbow

- Hastelloy Half Couplings

- Hastelloy Full Couplings

- Hastelloy 3000 LBS Socket Weld Fittings

- Hastelloy 3000 LBS Threaded Fittings

- Hastelloy Alloy Forged Pipe Fittings

- Hastelloy® Alloy Socketweld Forged Fittings

- Hastelloy High Pressure Forged Pipe Fittings

- ASME B16.11 Hastelloy Alloy Forged Pipe Fittings

We Serve Application Industry

Application Industry

Socket weld Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Hastelloy Forged Fittings Across the Globe

Domestic Supply Hastelloy Forged Fittings

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004