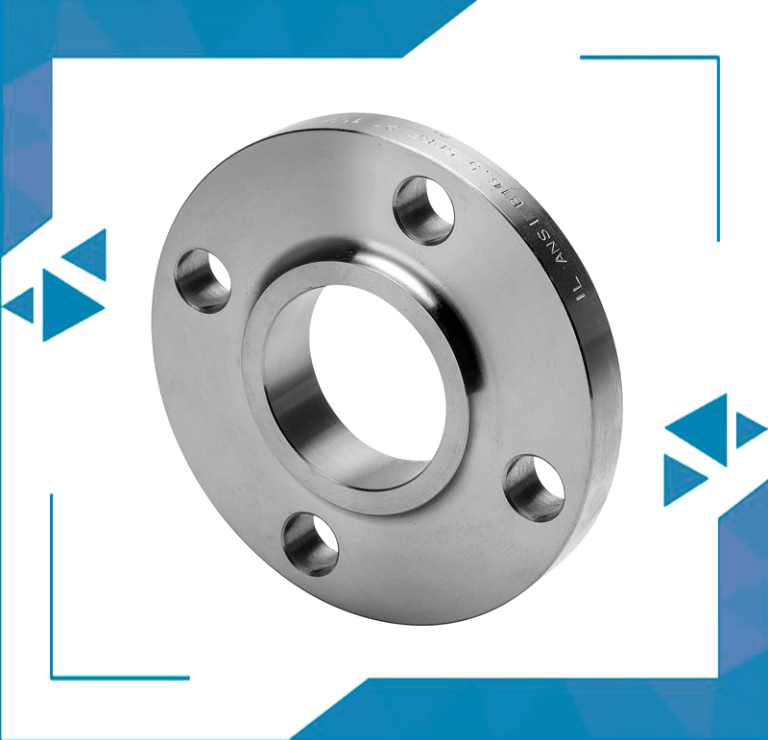

Stainless Steel 904L Flanges Manufacturer

Home / Stainless Steel Flanges Fittings / Stainless Steel 904L Flanges

Global Steel India is a leading supplier of stainless steel 904L flanges.

Stainless Steel 904L flange is made from austenitic alloy steel that is utilized in applications requiring moderate to high corrosion resistance. They can be employed in a variety of process settings. Copper is added to its alloy to increase resistance to harsh acids, such as sulphuric acid. When compared to 316L and 317L stainless steel grades, the magnetic characteristics of stainless steel 904L flanges are stronger.

Table Of content

- About Stainless Steel 904L Flanges

- Specification List of SS 904L Flanges

- Equivalent Grades Of Stainless Steel 904L Flanges

- Manufacturing Standards of ASTM A182 F904L Flanges

- Different Types of Stainless Steel 904L Flanges

- Available Stock of SS 904L Flanges

- SS 904L Flanges Weight Chart

- Stainless Steel 904L Pipe Flange Dimensions

- 904L Stainless Steel Flanges Pressure Rating

- Chemical Structure of Stainless Steel 904L Flanges

- Mechanical Properties of SS 904L Flanges

- We Serve Application Industry

- We Export Stainless Steel 904L Flanges Across the Globe

- Domestic Supply Stainless Steel 904L Flanges

It has strong acid resistance, as well as resistance to crevice corrosion and stress corrosion cracking in acidic conditions. They’re also noted for their ability to withstand pitting in chloride solutions. This is due to the presence of high amounts of nickel in its alloy. Stainless steel 904L flanges remain non-magnetic at all times. They are easy to weld and can be welded by using all conventional methods. Stainless steel 904L flanges do not require pre-heat and post-weld heat treatments. Grade 904L stainless steel flanges can be subjected to hot cracking in constrained weldment. Stainless steel 904L flanges are high in purity and have low sulphur content. According to AS 1554.6, Grade 904L electrodes and rods are used for welding grade 904L stainless steel.

Stainless steel 904L Flanges are used in several industries and applications like – Oil refineries, seawater cooling devices, gas scrubbing plants, pulp and paper processing industries, and Acetic/phosphoric/sulphuric acid processing plants, etc.

The quality of the products we offer is of topmost importance. All products at Global Steel go through strict quality tests before dispatching like the Hardness test, Flaring test, Chemical Analysis – Spectro Analysis Pitting resistance test, Intergranular Corrosion Test, Positive Material Identification – PMI Testing, Micro and Macro test, etc.

What makes SS 904L flanges so unique?

SS 904L flanges are unique due to their high levels of chromium, nickel, and molybdenum, which provide excellent resistance to corrosion in a wide range of environments, including those containing sulfuric acid and other aggressive chemicals. Additionally, SS 904L flanges have high strength, good formability, and excellent weldability, making them well-suited for various industrial applications, such as chemical and petrochemical processing, oil and gas refining, and pulp and paper manufacturing.

How strong is SS 904L flanges?

SS 904L flanges have high strength and excellent corrosion resistance. The strength of the flanges depends on the specific manufacturing process and heat treatment used, as well as the dimensions and design of the flange itself. Generally, SS 904L has a tensile strength of around 490 MPa and a yield strength of around 220 MPa. These properties make SS 904L flanges well-suited for use in a range of demanding industrial applications.

Do SS 904L flanges rust?

SS 904L flanges are highly resistant to rust and corrosion in many environments. The high levels of chromium, nickel, and molybdenum in the alloy provide excellent resistance to rust and corrosion in harsh and aggressive environments, including those containing sulfuric acid and other corrosive chemicals. However, if the flanges are exposed to highly corrosive or oxidizing conditions for an extended time, they may eventually show signs of corrosion or rust.

Specification of SS 904L Flanges

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Manufacturing Standards

| ASME/ANSI B16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B16.36 | Orifice Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Different Types

SS 904L Slip On Flanges

SS 904L Blind Flanges

SS 904L Socket Weld Flanges

SS 904L Weld Neck Flanges

SS 904L Reducing Flanges

SS 904L Orifice Flanges

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel 904L Flanges as per DIN, ASTM, ASME, BS, EN, JIS or ANSI Standard.

Available Stock

- ASME B16.47 SS 904L Spades Ring Spacers Flanges

- Grade 904L Stainless Steel Flanges

- 904L SS Flanges

- UNS N08904 Stainless Steel Lap Joint Flanges

- Stainless Steel 904L Plate Flange

- Suppliers of 904L Stainless Steel Flanges

- Type 904L SS Industrial Forged Flanges

- SS 904L Groove Flanges

- UNS N08904 Male & Female Flanges

- 904L Stainless Steel Nipoflange

- 904L SS Pipe Flange

- Stainless Steel 904L Tongue Flanges

- ASTM A182 F904L Stainless Steel Flanges

- Stainless Steel 904L PN 10 Flange

- INOX 904L Flanges

- SS 904L Lapped Joint Flanges

- Stainless Steel 904L BS Standard Table E

- 904L SS 150 LBS Threaded Flanges

- SS 904L DIN Flanges

- SS 904L British Standard Table D Pipe Flanges

- Stainless Steel 904L Long Welding Neck Flange

- 904L SS Weldo Flanges

- SS 904L Flat Face Flanges

- SS 904L Spectacle Blind Flanges

- Austenitic Stainless Steel 904L Flanges

- SS 1.4539 1500 LBS Flanges

- Stainless Steel 904L Nipo Flanges

- Stainless Steel 904L Screwed Flanges

- Stainless Steel 904L Spades Ring Spacers Flanges

Weight Chart

15mm (1/2″) Stainless Steel 904L Flanges Weight Chart

Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Chemical Structure

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

We Serve Application Industry

Application Industry

ANSI / ASME 16.5, 16.48, 16.47 Flanges applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Stainless Steel 904L Flanges Across the Globe

Domestic Supply Stainless Steel 904L Flanges

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004