Stainless Steel 317 / 317L Pipe Fittings Manufacturer

Home / Stainless Steel Pipe Fittings / Stainless Steel 317 Pipe Fittings

Stainless steel 317 pipe fittings are a type of pipe fittings that are made from high-quality austenitic stainless steel. The composition of this steel is primarily made up of iron, carbon, nickel & chromium. These elements give the steel unique properties, including excellent resistance to corrosion and high-temperature environments.

Stainless Steel 317 Pipe Fittings and Stainless Steel 317L Pipe Fittings differ primarily in carbon content. SS 317 contains higher carbon (0.08% max), while SS 317L has lower carbon (0.03% max), promoting better resistance to sensitization and intergranular corrosion in high-temperature applications. This makes 317L more suitable for welding and elevated temperature environments, while 317 is used in general corrosion-resistant applications. The choice depends on the need for corrosion resistance and resistance to sensitization in specific conditions.

Table Of content

- About Stainless Steel 317,317L Pipe Fittings

- Specification List of SS 317,317L Pipe Fittings

- Equivalent Grades Of Stainless Steel 317,317L Pipe Fittings

- Manufacturing Standards of ASTM A403 WP317,317L Pipe Fittings

- Different Types of Stainless Steel 317,317L Pipe Fittings

- Available Stock of SS 317,317L Buttweld Pipe Fittings

- Stainless Steel 317,317L Pipe Fittings Dimensional Tolerances

- Chemical Structure of Stainless Steel 317,317L Pipe Fittings

- Mechanical Properties of SS 317,317L Pipe Fittings

- We Serve Application Industry

- We Export Stainless Steel 317,317L Pipe Fittings Across the Globe

- Domestic Supply Stainless Steel 317,317L Pipe Fittings

One of the significant benefits of using Stainless Steel 317 Pipe Fittings is their superior corrosion resistance. This makes them ideal for use in harsh environments, such as those exposed to salt water or chemicals. Stainless steel 317 pipe fittings are also highly durable & can withstand high temperatures, making them suitable for high-temperature environments.

Another significant advantage of using stainless steel 317 pipe fittings is their strength. This means they can handle higher pressure. They are also very easy to maintain and clean, making them an economical choice in the long run. The high-quality stainless steel products we provide at Global Steel include Stainless Steel 321 Pipe Fittings, Stainless Steel 347 Pipe Fittings and more.

Stainless steel 317 pipe fittings are widely used in various industries, including chemical processing, food processing & oil and gas. They are popular in industries where the pipes and fittings are exposed to harsh and corrosive environments. Stainless steel 317 pipe fittings are also commonly used in construction and infrastructure projects. We provide an extensive range of products, such as Carbon Steel Olets, Nickel Alloy 201 Pipe Fittings and more.

Stainless steel 317 pipe fittings offer unique properties ideal for specific applications. These fittings are highly resistant to corrosion and can withstand high temperatures. They are also non-magnetic and have excellent formability. They are stronger than some other types of stainless steel. They are still incredibly durable and have excellent fatigue strength.

Stainless steel 317 pipe fittings are excellent for durable, corrosion-resistant, and high-temperature-resistant fittings. They are widely used in many industries & have many benefits, including their strength and ease of maintenance.

How is a Stainless Steel 317 pipe fitting used?

Stainless Steel 317 pipe fittings are often used in factory piping systems due to their durability and resistance to corrosion and heat. They provide a reliable connection from one pipe to another, allowing liquids or gases to flow freely through a particular pathway. In addition, they can be used for repairs as the material allows for easy welding, making them suitable for the construction of both commercial and residential properties. Finally, this type of fitting is economical as it is relatively inexpensive compared to other types of stainless steel. For these reasons, Stainless Steel 317 pipe fittings are an ideal choice for factory piping systems and projects.

What are the dimensions of 317L stainless steel pipe fittings?

Regarding pipe fittings, stainless steel 317L provides superior strength and functionality. The dimensions of these stainless steel 317 pipe fittings vary depending on the application but generally follow an ANSI/ASME B16.9 standard. In particular, the thickness of these fittings ranges from 0.017″ to 4″. As for wall thickness, it usually ranges from 16 to 11 gauge. Each dimension is carefully considered to form a reliable connection between different systems without compromising strength or corrosion resistance. Overall, this type of stainless steel offers greater longevity than most other materials in the same categories.

What is the pressure rating of 317 stainless steel pipe fittings?

When considering the pressure rating of 317 stainless steel pipe fittings, it is essential to consider that this material can withstand high temperatures and corrosive environments. It is a relatively low-pressure rated material with maximum working pressures of 275 psi for straight, seamless fittings and 150 psi for all other configurations (socket weld, threaded & butt weld). Due to its superior corrosion resistance properties compared to many other materials, it can still be a viable choice even at slightly lower pressure ratings in certain situations. However, it is essential to ensure there will be no adverse effects regarding your application before making any final decisions.

Specification SS 317,317L Pipe Fittings

| Standards | ASTM A403 / ASME SA403 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size |

|

| Type | Seamless / Welded / Fabricated |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

Manufacturing Standards

| ASME B16.9 ASTM A403 WP317 Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Different Types

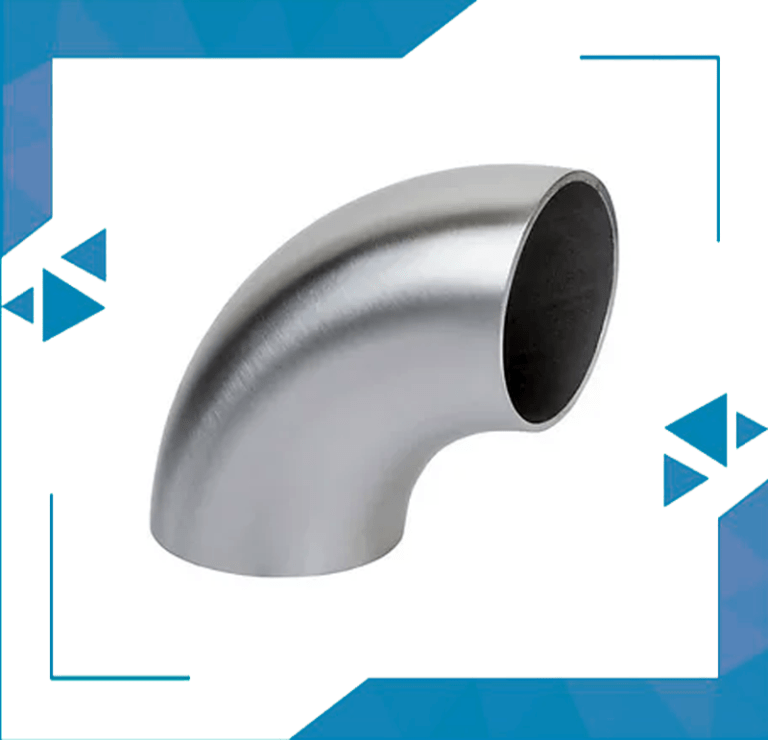

SS 317,317L Pipe Elbow

SS 317,317L Pipe Tee

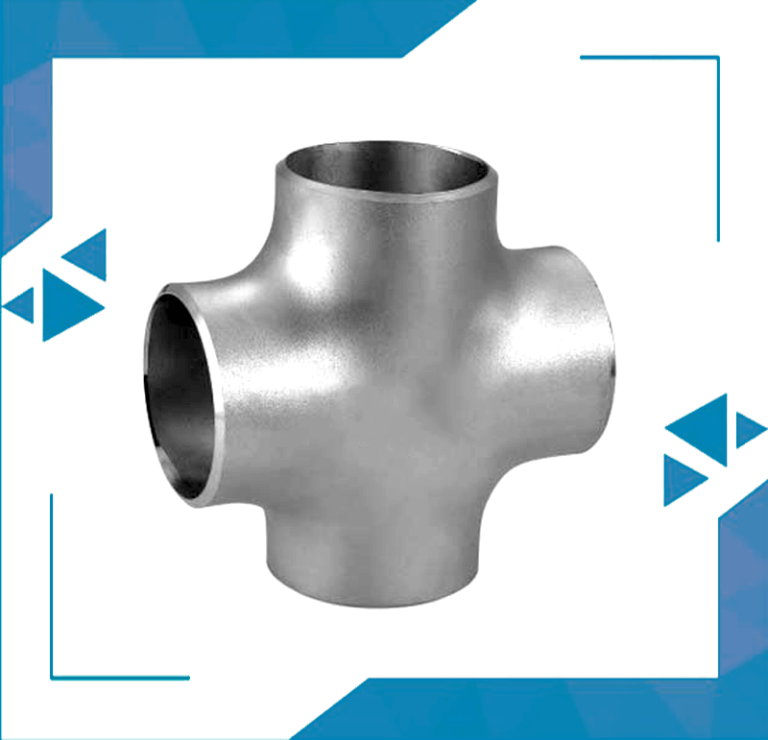

SS 317,317L Pipe Cross

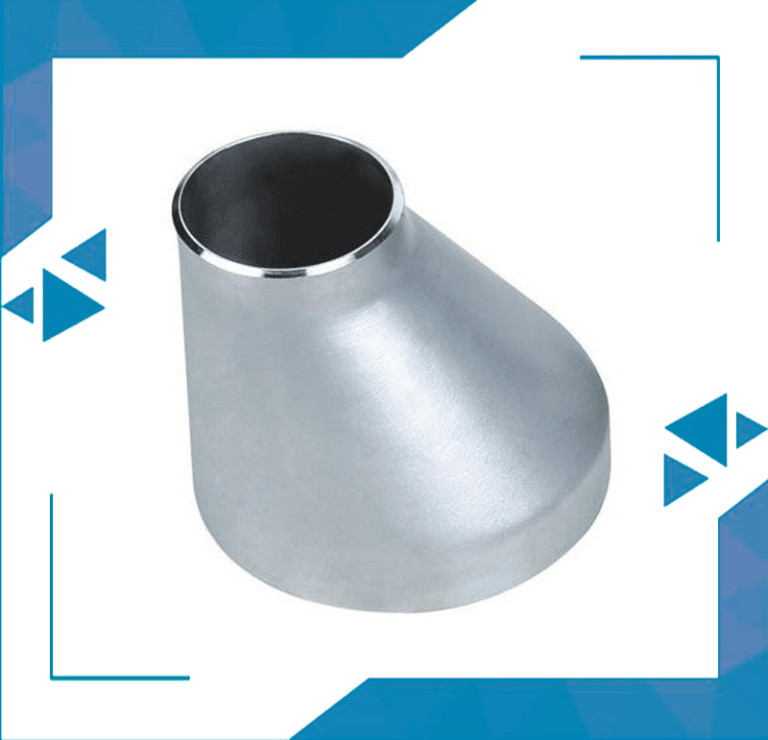

SS 317,317L Reducers

SS 317,317L Pipe Cap

SS 317,317L Stub End

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel 317/317L Buttweld Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Stainless Steel 317 Pipe Reducing Tee

- ANSI B16.9 Stainless Steel 317 Pipe Caps

- ASME B16.28 SS 317 Two Joint Pipe Fittings

- INOX 317L Buttweld Pipe Fittings

- UNS S31700 Buttweld Fittings

- ASTM A403 WP 317L Stainless Steel Lateral Tee

- SS 317L 3D Elbow

- Type 317L SS Industrial Buttweld Fittings

- UNS S31703 Stainless Steel 2D Elbow

- Grade 317 Stainless Steel Pipe Fittings

- SS 317L Reducers

- 317 SS Two Halve Butt weld Fittings

- 317 Stainless Steel 1D Elbow

- Stainless Steel 317L 45° Short Radius Elbow

- 317 SS Pipe Fittings

- Stainless Steel 317 Lap Joint Stub Ends

- SS 1.4449 Two Joint Pipe Fittings

- Stainless Steel 317 Reducing Elbow

- Stainless Steel 317L Buttweld Pipe Nipple

- Stainless Steel 317L Butt weld Fittings

- Stainless Steel 317 180° Buttweld Elbow

- ANSI B16.28 317L SS Seamless Pipe Fittings

- SS 317 Butt Weld Elbows 90°-SR- ASME B16.9

- Stainless Steel 317 Buttweld Elbow

- Stainless Steel 317L Concentric Reducer

- 317 SS Stub End

- SS 317 Eccentric Reducer

- SS 317 90° LR Elbow

- Austenitic Stainless Steel 317L 45 Degree Pipe Elbow

- Stainless Steel 317L Pipe Bends

- SS 317 Buttweld Pipe Fittings

Dimensional Tolerances

| 1/2 TO 2-1/2 | +1/16 | ±1/32 | Not less than 87-1/2% of Normal Thickness | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 12 to 4 | 1/32 | 1/16 |

| -1/32 | 5 to 8 | 1/16 | 1/8 | |||||||||

| 3 TO 3-1/2 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 10 to 12 | 3/32 | 3/16 | |

| 4 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 14 to 16 | 3/32 | 1/4 | |

| 5 TO 8 | +1/32 | ±1/16 | ±1/16 | ±1/16 | ±1/4 | ±1/4 | ±1/4 | ±1/32 | 18 to 24 | 1/8 | 3/8 | |

| -1/16 | ||||||||||||

| 10 TO 18 | +1/16 | ±1/8 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | All dimensions are in inches | |||

| -1/8 | ||||||||||||

| 20 TO 24 | +1/4 | ±3/32 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | ||||

| -3/32 | ||||||||||||

Chemical Structure

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

- Stainless Steel Products

- Stainless Steel Pipe Fittings

- Stainless Steel 304 / 304L / 304H Pipe Fittings

- Stainless Steel 310 / 310S / 310H Pipe Fittings

- Stainless Steel 316 / 316L / 316H / 316TI Pipe Fittings

- Stainless Steel 317 / 317L Pipe Fittings

- Stainless Steel 321 / 321H Pipe Fittings

- Stainless Steel 347 / 347H Pipe Fittings

- Stainless Steel 904L Pipe Fittings

- Stainless Steel Forged Fittings

- Stainless Steel Flanges

- Stainless Steel Fasteners

- Stainless Steel Olets

- Stainless Steel Instrumentation Accessories

- Stainless Steel Instrumentation Fittings

- Stainless Steel Valves

- Stainless Steel Pipe Fittings

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004