Stainless Steel 310/ 310S / 310H Pipe Fittings Manufacturer

Home / Stainless Steel Pipe Fittings / Stainless Steel 310 Pipe Fittings

Stainless steel 310 fittings are made of iron, chromium, and nickel, making them highly durable and resistant to corrosion, heat & oxidation. These fittings are designed for high-temperature environments, making them ideal for industrial, chemical, and petrochemical processes.

Using Stainless Steel 310 Pipe Fittings has many benefits, including high-temperature resistance, corrosion resistance & overall durability. They are also easy to clean and can be used in cleanrooms & sanitary applications. They require minimal maintenance, ensuring they will last for decades.

Table Of content

- About Stainless Steel 310, 310S, 310H Pipe Fittings

- Specification of SS 310, 310S, 310H Pipe Fittings

- Equivalent Grades .

- Manufacturing Standards of ASTM A403 WP310, 310S, 310H Pipe Fittings

- Different Types of Stainless Steel 310, 310S, 310H Pipe Fittings

- Available Stock of SS 310, 310S, 310H Buttweld Pipe Fittings

- Stainless Steel 310, 310S, 310H Pipe Fittings Dimensional Tolerances

- Chemical Structure of Stainless Steel 310, 310S, 310H Pipe Fittings

- Mechanical Properties of SS 310, 310S, 310H Pipe Fittings

- We Serve Application Industry

- We Export Stainless Steel 310, 310S, 310H Pipe Fittings Across the Globe

- Domestic Supply Stainless Steel 310, 310S, 310H Pipe Fittings

Stainless Steel 310S Pipe Fittings are often used in the chemical, petrochemical, and pharmaceutical industries. High temperature and corrosion resistance are essential in these industries to ensure quality products. UNS S31008 Butt Weld Fittings can also be found in other industries, such as food and beverage production, oil refineries, and power generation.

Stainless Steel 310H Pipe Fittings possess unique properties that make them ideal for high-temperature applications. These properties include high-temperature strength, excellent resistance to oxidation and corrosion & exceptional toughness. SS 310H Butt Weld Fittings hold up well to repeated thermal cycling, meaning they can maintain their strength even under frequent changes in temperature. The high-quality Stainless Steel Products we provide at Global Steel include Stainless Steel 317 Pipe Fitting, Stainless Steel 316 Pipe Fitting and more.

The mechanical strength and stability of SS 1.4841 Pipe Fittings are of utmost significance, particularly in industries that demand high-pressure and heavy-load conditions. Their reliability in withstanding mechanical stress ensures uninterrupted fluid flow and prevents potential system failures. These fittings are known for their versatility, featuring excellent weldability and formability, which streamline installation processes and allow for adaptable designs tailored to specific requirements. We provide an extensive range of products, such as Alloy Steel A182 F9 Flanges,Titanium Forged Fittings, and many others.

Their smooth surface finish minimizes the accumulation of contaminants, making them easy to clean and vital in maintaining product purity and quality. SS 310 Pipe Fittings collectively contribute to their pivotal role across petrochemicals, energy, and manufacturing industries, ensuring efficient fluid management, longevity, and reliability within intricate industrial processes.

What factors to consider when installing stainless steel 310H pipe fittings?

Several factors must be considered when installing stainless steel 310H pipe fittings to ensure safe and reliable performance. These factors include proper alignment and support of the pipes, accurate measurement and cutting of the fittings, careful welding or brazing techniques, compliance with industry standards and regulations, and thorough testing and inspection to ensure the joint is secure and leak-free. Additionally, the installation environment should be clean and free of debris that could contaminate the system or damage the fittings.

What is the durability of stainless steel 310 pipe fitting?

Stainless steel 310H pipe fittings are known for their high durability due to their excellent resistance to corrosion and high temperatures. They are designed to withstand harsh environments and extreme temperatures, making them suitable for various industrial applications. When properly installed and maintained, stainless steel 310H pipe fittings can provide long-term performance and a low-maintenance solution for fluid handling systems. Their durability is also reflected in their ability to resist cracking, scaling, and deformation under stress, ensuring a reliable and leak-free connection for years.

Which chemicals will damage SS 310H pipe fiitngs?

Stainless steel 310H pipe fittings are known for their excellent corrosion resistance to various chemicals, acids, and alkalis. However, they can be susceptible to damage from certain chemicals, particularly in high concentrations or elevated temperatures. Some chemicals that can cause damage to stainless steel 310H pipe fittings include hydrochloric acid, sulfuric acid, nitric acid, chlorine gas, and ammonia. It is essential to consult with chemical compatibility charts and industry standards to ensure that the appropriate materials are selected for use with specific chemicals and environments.

Specification List of SS 310, 310S, 310H Pipe Fittings

| Standards | ASTM A403 / ASME SA403 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size |

|

| Type | Seamless / Welded / Fabricated |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

Manufacturing Standards of ASTM A403 WP310, 310S, 310H Pipe Fittings

| ASME B16.9 ASTM A403 WP310 Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Different Types

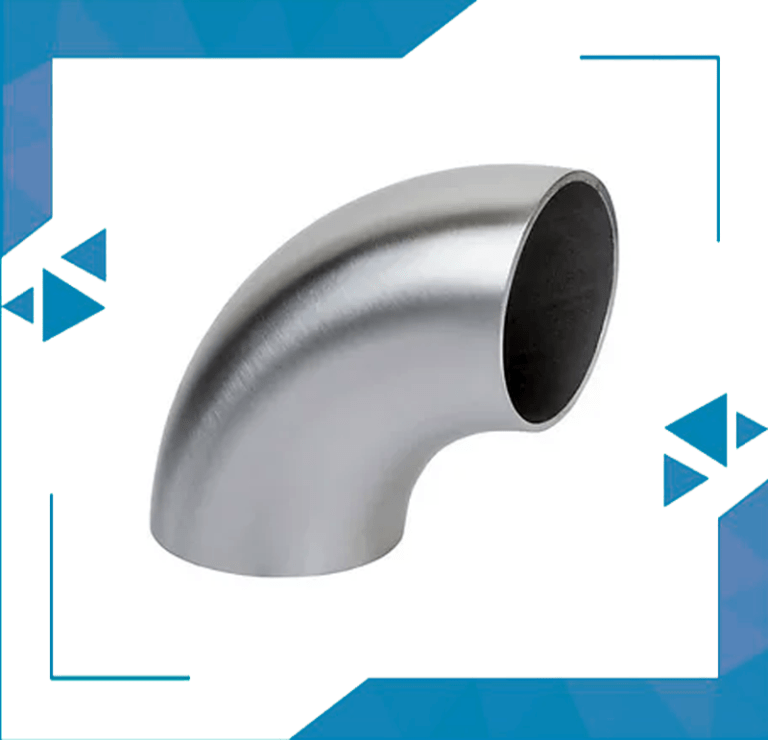

SS 310, 310S, 310H Pipe Elbow

SS 310, 310S, 310H Pipe Tee

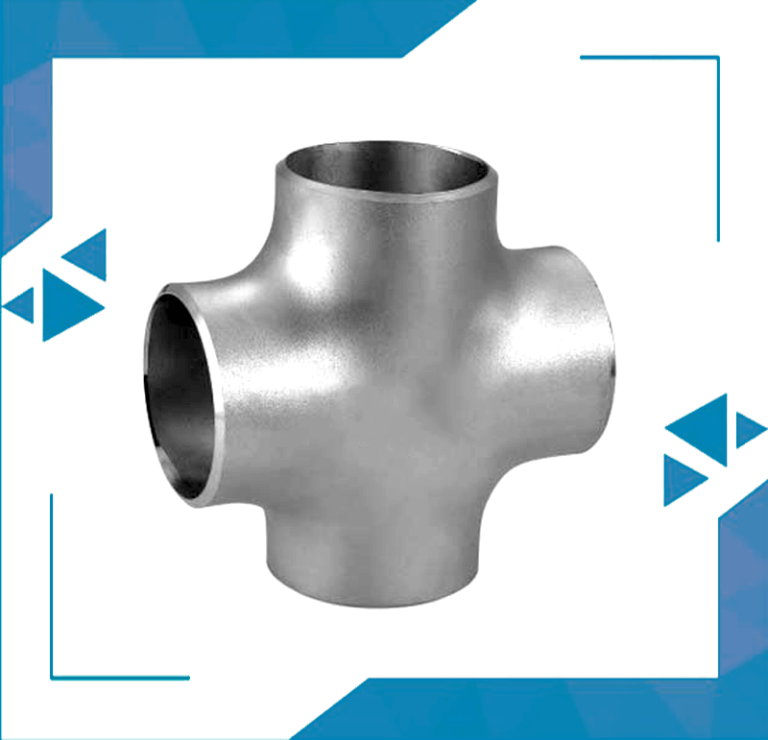

SS 310, 310S, 310H Pipe Cross

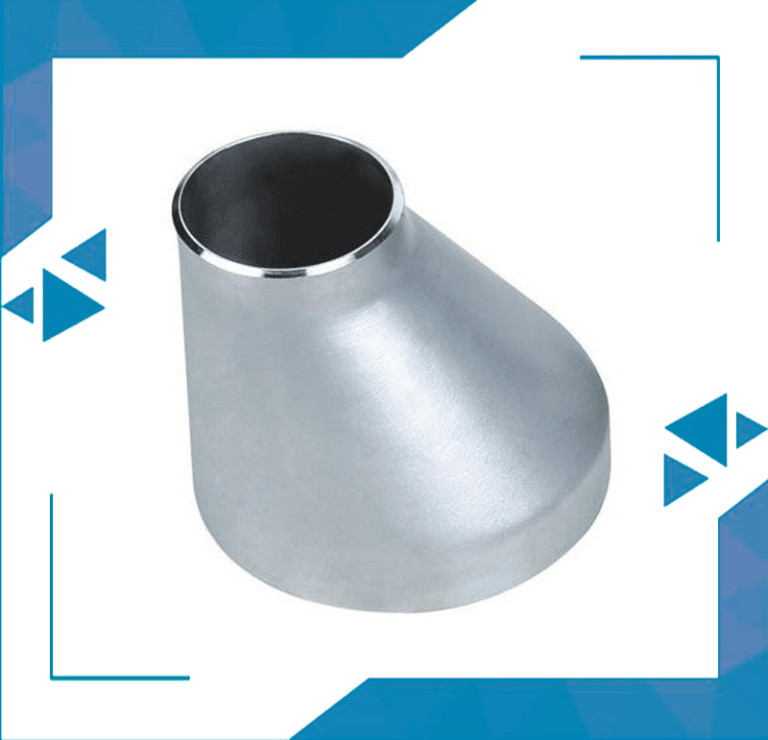

SS 310, 310S, 310H Reducers

SS 310, 310S, 310H Pipe Cap

SS 310, 310S, 310H Stub End

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel 310 / 310S / 310H Buttweld Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Type 310H SS Industrial Buttweld Fittings

- SS 310H Reducers

- SS 310H 3D Elbow

- Stainless Steel 310 Lap Joint Stub Ends

- 310S SS Pipe Fittings

- Grade 310 Stainless Steel Pipe Fittings

- UNS S31008 Stainless Steel 2D Elbow

- ANSI B16.9 Stainless Steel 310 Pipe Caps

- 310 Stainless Steel 1D Elbow

- ASME B16.28 SS 310S Two Joint Pipe Fittings

- 310 SS Two Halve Butt weld Fittings

- Stainless Steel 310H 45° Short Radius Elbow

- ASTM A403 WP 310H Stainless Steel Lateral Tee

- INOX 310 Buttweld Pipe Fittings

- Stainless Steel 310S Pipe Reducing Tee

- SS 1.4841 Two Joint Pipe Fittings

- UNS S31000 Buttweld Fittings

- Stainless Steel 310H Pipe Bends

- Stainless Steel 310 Reducing Elbow

- SS 310 Butt Weld Elbows 90°-SR- ASME B16.9

- Stainless Steel 310S 180° Buttweld Elbow

- SS 310S Eccentric Reducer

- Austenitic Stainless Steel 310H 45 Degree Pipe Elbow

- Stainless Steel 310 Buttweld Pipe Nipple

- SS 310S 90° LR Elbow

- Stainless Steel 310H Concentric Reducer

- SS 310H Pipe Cross Suppliers

- ANSI B16.28 310S SS Seamless Pipe Fittings

- SS 310S Buttweld Pipe Fittings

- Stainless Steel 310S Buttweld Elbow

Dimensional Tolerances

| 1/2 TO 2-1/2 | +1/16 | ±1/32 | Not less than 87-1/2% of Normal Thickness | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 12 to 4 | 1/32 | 1/16 |

| -1/32 | 5 to 8 | 1/16 | 1/8 | |||||||||

| 3 TO 3-1/2 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 10 to 12 | 3/32 | 3/16 | |

| 4 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 14 to 16 | 3/32 | 1/4 | |

| 5 TO 8 | +1/32 | ±1/16 | ±1/16 | ±1/16 | ±1/4 | ±1/4 | ±1/4 | ±1/32 | 18 to 24 | 1/8 | 3/8 | |

| -1/16 | ||||||||||||

| 10 TO 18 | +1/16 | ±1/8 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | All dimensions are in inches | |||

| -1/8 | ||||||||||||

| 20 TO 24 | +1/4 | ±3/32 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | ||||

| -3/32 | ||||||||||||

Chemical Structure

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| SS 310H | 0.04 – 0.10 | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | – | 19.00 – 21.00 | 53.885 min |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

- Stainless Steel Products

- Stainless Steel Pipe Fittings

- Stainless Steel 304 / 304L / 304H Pipe Fittings

- Stainless Steel 310 / 310S / 310H Pipe Fittings

- Stainless Steel 316 / 316L / 316H / 316TI Pipe Fittings

- Stainless Steel 317 / 317L Pipe Fittings

- Stainless Steel 321 / 321H Pipe Fittings

- Stainless Steel 347 / 347H Pipe Fittings

- Stainless Steel 904L Pipe Fittings

- Stainless Steel Forged Fittings

- Stainless Steel Flanges

- Stainless Steel Fasteners

- Stainless Steel Olets

- Stainless Steel Instrumentation Accessories

- Stainless Steel Instrumentation Fittings

- Stainless Steel Valves

- Stainless Steel Pipe Fittings

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004