Stainless Steel 317 / 317L Forged Fittings Manufacturer

Home / Stainless Steel Forged Fittings / Stainless Steel 317 Forged Fittings

Welcome to our comprehensive collection of Stainless Steel 317 and 317L Forged Fittings, meticulously created to meet the most elevated guidelines of quality and strength. Stainless Steel 317 Forged Fittings are precision-engineered components outlined for utilization in different mechanical applications, especially when erosion resistance is vital. These fittings are forged from high-quality stainless steel grade 317, which is known for its excellent erosion resistance, tall, pliable quality, and strength. The fittings are fastidiously made to meet the requested necessities of different businesses, guaranteeing solid execution in challenging conditions. As a trusted manufacturer and supplier, Global Steel takes pride in advertising a different range of stainless steel forged fittings to cater to different mechanical needs.

Table Of content

- About Stainless Steel 317, 317L Forged Fittings

- Specification List of SS 317, 317L Forged Fittings

- Equivalent Grades Of Stainless Steel 317, 317L Forged Fittings

- Manufacturing Standards of ASTM A182 F317, 317L Forged Fittings

- Different Types of Stainless Steel 317, 317L Forged Fittings

- Available Stock of SS 317, 317L Socketweld Forged Fittings

- Chemical Structure of Stainless Steel 317, 317L Forged Fittings

- Mechanical Properties of SS 317, 317L Forged Fittings

- We Serve Application Industry

- We Export Stainless Steel 317, 317L Forged Fittings Across the Globe

- Domestic Supply Stainless Steel 317, 317L Forged Fittings

Stainless Steel 317 Forged Fittings

Elevate your channeling frameworks with our premium Stainless Steel 317 Forged Fittings, outlined to supply extraordinary execution in challenging situations. These fittings, manufactured in compliance with ASTM A182 benchmarks, brag predominant erosion resistance and tall, malleable quality. Our SS 317 Forged Fittings, and Stainless Steel 317 Valves are perfect for high-pressure applications and guarantee unwavering quality and longevity.

Explore a flexible extension incorporating SS 317 Socket Weld Fittings and SS 317 Threaded Fittings. The precision-engineered 317 Stainless Steel Hex Plug and Threaded Elbow, alongside UNS S31700 Produced Fittings, ensure a consistent integration into your channeling system. Global Steel stands out as a driving SS 317 Forged Fittings Supplier, conveying brilliance over India and beyond.

Stainless Steel 317L Manufactured Fittings

Find the excellence of Stainless Steel 317L Forged Fittings, where development meets strength. Our 317L SS Manufactured Fittings, made with accuracy by ASTM A182 measures, offer remarkable resistance to erosion and extraordinary temperatures—accomplice with us for a solid supply of SS 317L Attachment Weld Fittings and Threaded Fittings, with other products like SS 316 Forged Fittings. Global Steel, recognized as a head SS 317L Forged Fittings manufacturer, guarantees that each fitting, counting the UNS S31703 forged Fittings, meets the most elevated industry standards. The ASTM A213 317L SS Forged Fittings in our stock confirms our commitment to quality—Tally on us for unparalleled mastery and a prepared 317L Stainless Steel High-Pressure Fittings stock.

As an industry pioneer, Global Steel emphasizes availability, not quality. Advantage from our broad stock, with 317 SS Forged Fittings prepared for quick conveyance. Our commitment to greatness expands to giving SS 317L Forged Fittings and DSS S32205 Forged Fittings globally, making us your trusted accomplice in producing victory for your ventures.

Rest simply knowing that our Stainless Steel 317 and SS 317L Socket weld Fittings acclimate to ASME SA182 guidelines. The utilization of Commotion 1.4401 Fashioned Fittings guarantees compatibility and tradable assembly of the requesting prerequisites of assorted industries. Select Worldwide Steel for a consistent mix of quality, reliability, and mastery in Stainless Steel 317 and 317L forged Fittings. Elevate your ventures with fittings that stand the test of time and execution. Stainless Steel 317 Forged Fittings, Stainless Steel 317L Forged Fittings and Incoloy 800H Forged Fittings offer robust solutions for applications requiring corrosion-resistant components. Both products adhere to ASTM A182 standards, providing assurance of quality and performance in diverse industrial settings. The choice between the two depends on the specific environmental conditions and the level of corrosion resistance required for a given application.

What is the pressure rating of 317/317L Forged Fittings?

Stainless Steel 317/317L Forged Fittings’ pressure rating depends on several factors, such as size, material grade, and wall thickness. However, typically they have a maximum pressure rating of 3000 PSI for 3000 lb fittings and 6000 PSI for 6000 lb fittings. These fittings are commonly used in high-pressure applications in the petrochemical, chemical, food, and pharmaceutical industries due to their excellent corrosion resistance and high-temperature strength. It is essential to consult with the manufacturer for specific pressure ratings for a particular application.

What is the temperature range for 317/317L Forged Fittings?

Stainless Steel 317/317L Forged Fittings have a wide operating temperature range and can handle temperatures from -450°F to 1500°F. This capability makes them suitable for applications like the petrochemical and chemical processing industries. The high-temperature strength of these fittings also makes them resistant to corrosion. A reliable choice for various industrial applications that require durability and resistance to harsh environments. It is important to note that the temperature range may vary depending on the specific application, and it is best to consult the manufacturer for a more accurate temperature range.

What is the difference between 317 and 317L SS Forged Fitting?

The main difference between Stainless Steel 317 and 317L Forged Fittings lies in their carbon content. 317L has a lower carbon content compared to 317, which makes it less prone to intergranular corrosion. This low carbon content also makes 317L more suitable for welding applications, as it is less susceptible to cracking or other forms of corrosion. However, both 317 and 317L offer excellent corrosion resistance and high-temperature strength, making them suitable for various industrial applications. When choosing between 317 and 317L, it is essential to consider the application’s specific requirements and consult with a professional to determine which grade is best suited for your needs.

Specification of SS 317, 317L Forged Fittings

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Thread | NPT, BSPT, BSPP |

| Forged Fittings Test Certificates |

|

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

Manufacturing Standards

| ASTM A182 / A182M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Stainless Steel Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel Forged fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged fittings socket-weld and threaded. Socket Weld and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Stainless steel fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Different Types

SS 317, 317L Forged Elbow

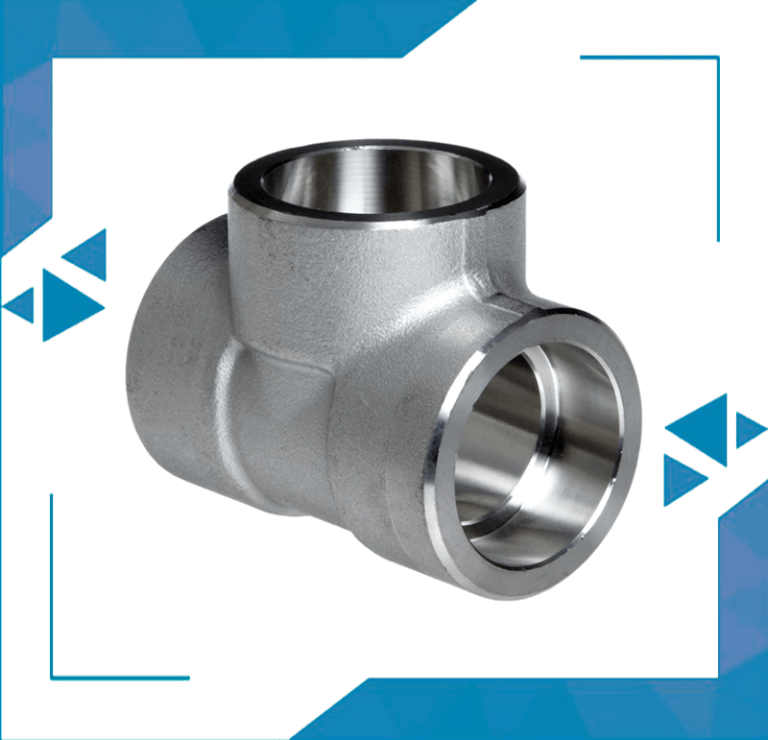

SS 317, 317L Forged Tee

SS 317, 317L Forged Cross

SS 317, 317L Coupling

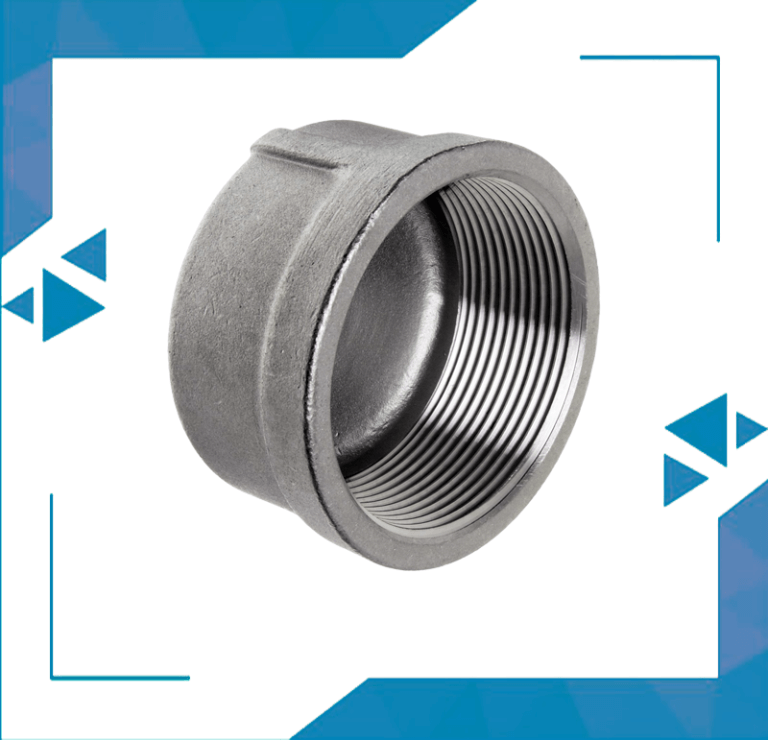

SS 317, 317L Forged Cap

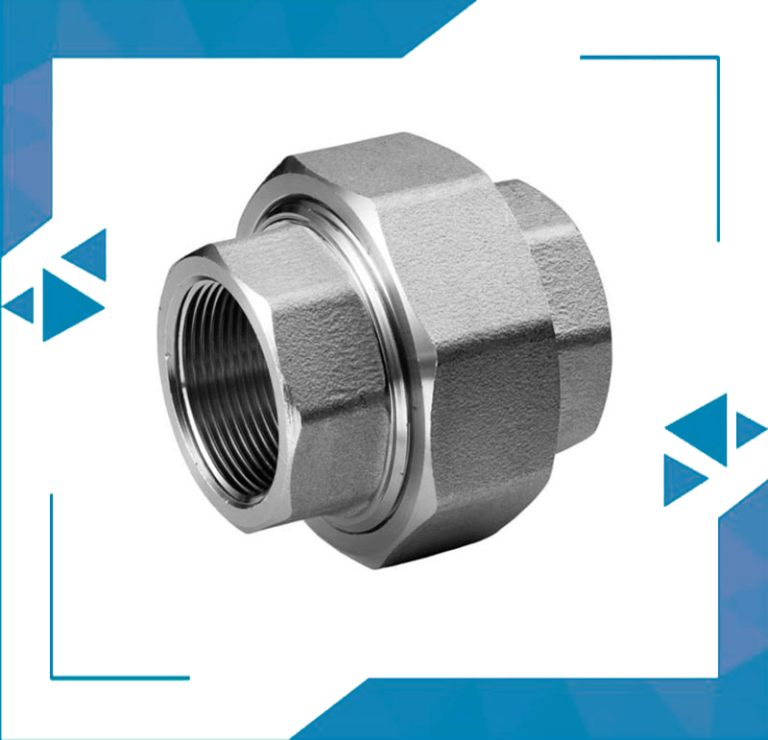

SS 317, 317L Union

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel 317 / 317L Socketweld Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- 317 Stainless Steel Hex Head Bushings

- Stainless Steel 317L Forged Reducing Tee

- ASME B16.11 SS 317L Forged Pipe Fittings

- INOX 317 Forged Fittings

- ASTM A182 F317 Stainless Steel Bushings

- 317L SS Forged Fittings

- ANSI B16.11 Stainless Steel 317 Forged Caps

- UNS S31703 Threaded Round Head Plugs

- UNS S31700 Socketweld Fittings

- SS 317L Socket Weld Elbow

- Stainless Steel 317L 45° Socket Weld Elbow

- Grade 317L Stainless Steel Forged Fittings

- SS 317L Scrwed Elbow

- 317 SS High Pressure Forged Pipe Fittings

- Type 317 SS Industrial Socketweld Fittings

- Stainless Steel 317 Hex Head Plug

- 317L SS Forged End Caps

- Stainless Steel 317 Forged Street Elbow

- SS 317L Full Couplings

- Stainless Steel 317L Socket Weld Fittings

- SS 317 Forged Threaded Fittings

- Stainless Steel 317L Socketweld Forged Elbow

- Austenitic Stainless Steel 317 Forged Pipe Fittings

- SS 317L Socketweld Forged Fittings

- SS 317L 90° Forged Elbow

- Stainless Steel 317 Reducing Insert

- Stainless Steel 317 Socketweld Forged Nipple

- SS 317L Forged Fittings

- Stainless Steel 317L Socketweld Forged Fittings

- SS 1.4449 3000LBS Socket Weld Fittings

- 317L SS 3000 LBS Threaded Fittings

- Stainless Steel 317 Half Couplings

Chemical Structure

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We Serve Application Industry

Application Industry

Socket weld Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Stainless Steel 317, 317L Forged Fittings Across the Globe

Czech Republic, Kuwait, Argentina, Singapore, Croatia, Brazil, Saudi Arabia, Peru, Oman, Tibet, Kazakhstan, Sweden, Macau, Algeria, Hungary, Ecuador, Iraq, Gabon, Hong Kong, United Arab Emirates, Thailand, Serbia, Portugal, Tunisia, Spain, Iran, Bolivia, Germany, Poland, Israel, columbia, Turkey, Venezuela, Ukraine, Indonesia, Trinidad & Tobago, Bangladesh, Ireland, Australia, Costa Rica, Canada, Belarus, Angola, Bahrain, Ghana, Libya, Puerto Rico, Zimbabwe, Denmark, Japan, Slovakia, Bulgaria, Estonia, Russia, Nepal, Kenya, Chile, Vietnam, Morocco, Gambia, Namibia, Philippines, Lithuania, Malaysia, Yemen, Lahore, Colombia, India, South Korea, United States, Belgium, Switzerland, Italy, Mexico, Afghanistan, Pakistan, Austria, Lebanon, Algiera, Qatar, Norway, Mongolia, Netherlands, South Africa, Taiwan, Greece, Nigeria, Egypt, China, Finland, Bhutan, France, New Zealand, United Kingdom, Jordan, Azerbaijan, Romania, Sri Lanka.

Domestic Supply Stainless Steel 317, 317L Forged Fittings

Ranchi, Jamshedpur, Nashik, Secunderabad, Bhopal, Gurgaon, Hyderabad, Haryana, Ahmedabad, Chandigarh, New Delhi, Bengaluru, Kolkata, Surat, Pune, Chennai, Jaipur, Howrah, Noida, Rajkot, mumbai, Visakhapatnam, Thane, Indore, Kanpur, Faridabad, Pimpri-Chinchwad, Navi Mumbai, Ernakulam , Nagpur, Ludhiana, Thiruvananthapuram.

Materials

- Stainless Steel Products

- Stainless Steel Pipe Fittings

- Stainless Steel Forged Fittings

- Stainless Steel 304 / 304L / 304H Forged Fittings

- Stainless Steel 310 / 310S / 310H Forged Fittings

- Stainless Steel 316 / 316L / 316H / 316Ti Forged Fittings

- Stainless Steel 317 / 317L Forged Fittings

- Stainless Steel 321 /321H Forged Fittings

- Stainless Steel 347 /347H Forged Fittings

- Stainless Steel 904L Forged Fittings

- Stainless Steel Flanges

- Stainless Steel Fasteners

- Stainless Steel Olets

- Stainless Steel Instrumentation Accessories

- Stainless Steel Instrumentation Fittings

- Stainless Steel Valves

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004