Inconel 600 Pipe Fittings Manufacturer

Home / Inconel Pipe Fittings / Inconel 600 Pipe Fittings

Global Steel is a notable and reliable manufacturer, supplier, and dealer of Inconel 600 Pipe Fittings. Pipe fittings are equipment used to connect pipes, valves, and flanges in a pipe system. The chemical composition of Inconel 600 Pipe Fittings gives it exceptional corrosion resistance. The fittings are able to withstand high pressures and high temperatures without corroding or dissolving easily. These fittings have superior strength and excellent mechanical properties.

Table Of content

- About Inconel 600 Pipe Fittings

- Specification List of Alloy 600 Pipe Fittings

- Equivalent Grades Of Inconel 600 Pipe Fittings

- Manufacturing Standards of ASTM B366 600 Pipe Fittings

- Different Types of Inconel 600 Pipe Fittings

- Available Stock of Alloy 600 Buttweld Pipe Fittings

- Inconel 600 Pipe Fittings Dimensional Tolerances

- Chemical Structure of Inconel 600 Pipe Fittings

- Mechanical Properties of Alloy 600 Pipe Fittings

- We Serve Application Industry

- We Export Inconel 600 Pipe Fittings Across the Globe

- Domestic Supply Inconel 600 Pipe Fittings

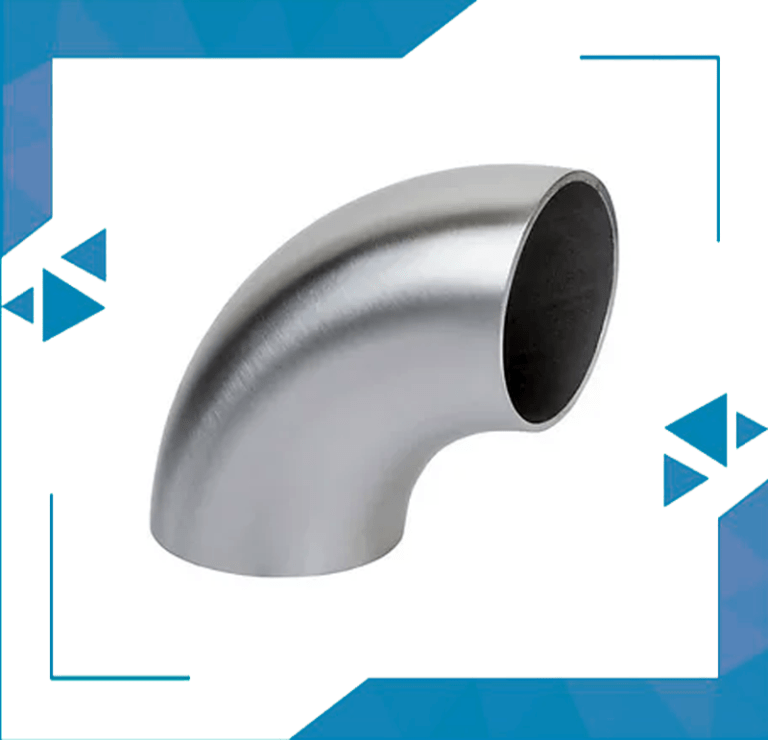

These Pipe Fittings are generally available at 45 degrees, 90 degrees, and 180 degrees, making them a popular choice for piping systems that require fluid or gas flowing in a particular direction. These elbows are available in different dimensions for different applications to ensure a tight seal and prevent any leaks.

As a manufacturer and supplier of Inconel 600 Pipe Fittings, we ensure that our elbows, pipe ferrules, nipples, reducers, etc, are unsurpassed in their resistance to stress corrosion cracking and alkaline solutions, making them suitable for use in chemical and nuclear processing facilities. Furthermore, our experts verify the quality of these Inconel 600 Fittings during the manufacturing process to remove any defects so that we can deliver excellence. We pack these pipes with standard packaging materials to deliver these Inconel Fittings safely to our buyers.

AISI Inconel 600 pipe fittings, has a composition of Nickel-Chromium Alloys, are of the highest quality, have excellent creep strength and metallurgical stability, have good oxidation resistance at high temperatures, and are impervious to organic and inorganic acids.

With the help of our modern manufacturing unit and advanced warehouse, we are able to fulfill orders in minimum time. The development of the large and hi-tech machines within our organization allows us to manufacture these Inconel 600 Fittings in huge quantities to satisfy the needs of our customers.

What is Inconel 600 pipe Fitting used for?

INCONEL 600 pipe fitting is used for various engine and airframe components that withstand high temperatures. Examples are lock wire, exhaust liners, and turbine seals. INCONEL alloy 600 pipes are used in the electronic field for such parts as cathode-ray tube spiders, thyratron grids, tube support members, and springs. The alloy is a standard material of construction for nuclear reactors. It has excellent resistance to corrosion by high-purity water, and no indication of chloride-ion stress-corrosion cracking in reactor water systems has been detected

What is the hardness of Inconel 600 fitting?

The Inconel 600 pipe fitting melting point ranges from 1354 to 1413 degrees C. This enables them to be used in heat treatment systems, chemicals, food processing, phenol condensers, pressure vessels, etc. Inconel 600 thermal conductivity is between 70 to 800 degrees F. They have this conductivity between 14.8 W/m·K to 20.9 W/m·K metric units. This helps in reducing running costs and operating materials. The Inconel 600 machinability enables it to be drawn in square, rectangular, circular, and various other shapes.

What temperature can Inconel withstand?

INCONEL 600 is used for its high strength, excellent fabric ability (including joining), and outstanding corrosion resistance. Service temperatures range from cryogenic to 1800°F (982°C). The composition is shown in Table 1. The strength of INCONEL alloy 625 is derived from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix; thus, precipitation-hardening treatments are not required. This combination of elements also is responsible for superior resistance to a wide range of corrosive environments of unusual severity as well as to high-temperature effects such as oxidation and carburization.

Specification of Alloy 600 Pipe Fittings

| Standards | ASTM AB366 / ASME SB366 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size |

|

| Type | Seamless / Welded / Fabricated |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Manufacturing Standards

| ASME B16.9 ASTM B366 600 Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Different Types

Inconel 600 Pipe Elbow

Inconel 600 Pipe Tee

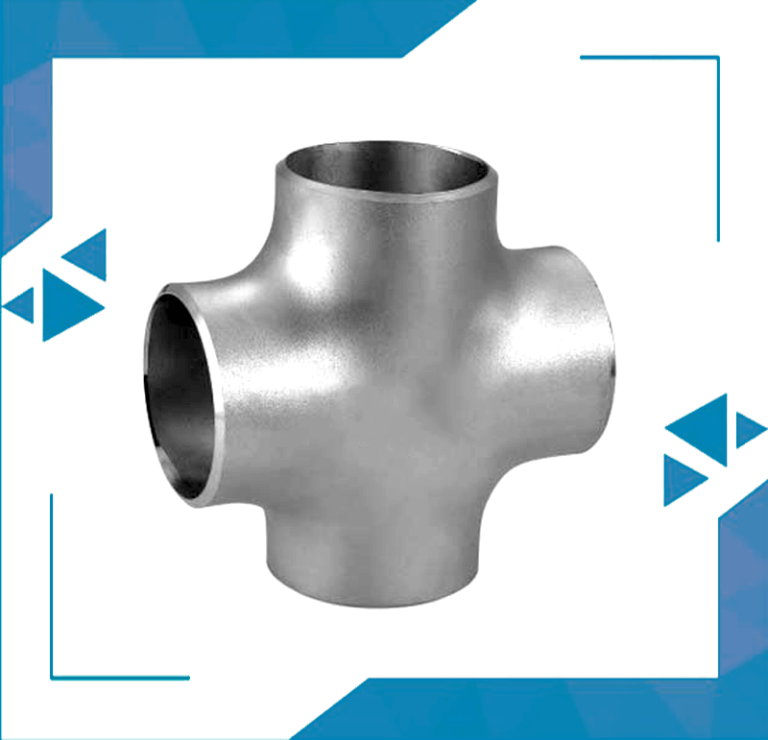

Inconel 600 Pipe Cross

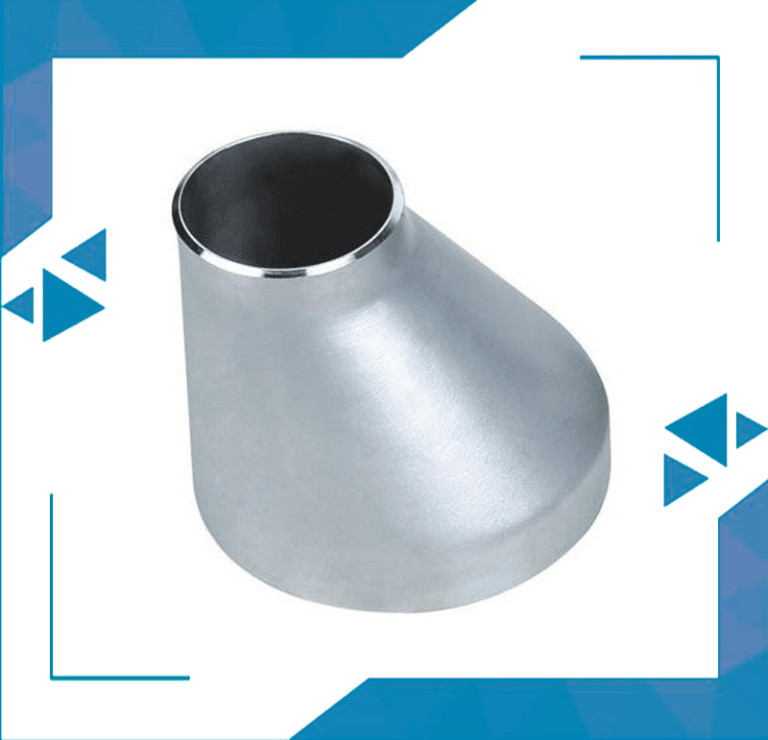

Inconel 600 Reducers

Inconel 600 Pipe Cap

Inconel 600 Stub End

Contact us to get a quick quote for your requirement.

We offer These Inconel 600 Buttweld Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Inconel® Alloy 600 Pipe Reducing Tee

- 600 Inconel Two Halve Butt weld Fittings

- Inconel 2.4816 Buttweld Pipe Fittings

- ASTM B366 600 Inconel Lateral Tee

- 600 Inconel Seamless Pipe Fittings

- 600 Inconel Seamless Fittings

- UNS N06600 Inconel 2D Elbow

- Type 600 Inconel Industrial Buttweld Fittings

- UNS N06600 Buttweld Fittings

- Inconel Alloy 600 Buttweld Pipe Fittings

- 600 Inconel 1D Elbow

- ASME B16.28 Inconel Alloy 600 Two Joint Pipe Fittings

- Alloy 600 3D Elbow

- Inconel 600 45° Short Radius Elbow

- Inconel® Alloy 600 Long Radius Elbow

- Grade 600 Inconel Pipe Fittings

- Inconel Alloy Gr 600 Pipe Fittings

- Alloy 600 Butt weld Elbow

- Inconel 600 45 Degree Pipe Elbow

- Inconel 600 ANSI/ ASME B16.9 1.5d Elbow

- Alloy 600 Butt Weld Elbows 90°-SR- ASME B16.9

- Inconel® Alloy 600 180° LR Return Bend

- Inconel 600 Concentric Reducer

- Inconel Grade 600 90° Seamless Elbow

- ANSI B16.28 600 Inconel Seamless Pipe Fittings

- Inconel® Alloy 600 90° LR Elbow

- Inconel 600 Butt weld Fittings

- Alloy 600 Buttweld Pipe Fittings

- Inconel 600 Reducing Elbow

- Inconel Alloy 600 180° Buttweld Elbow

- Inconel 600 Pipe Bends

- Inconel 600 Eccentric Reducer

- Inconel 600 Buttweld Pipe Nipple

- Alloy 2.4816 Two Joint Pipe Fittings

- Alloy 2.4816 Reducing Tee

- Inconel Alloy 600 Lap Joint Stub Ends

- ANSI B16.9 Inconel 600 Pipe Caps

Dimensional Tolerances

| 1/2 TO 2-1/2 | +1/16 | ±1/32 | Not less than 87-1/2% of Normal Thickness | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 12 to 4 | 1/32 | 1/16 |

| -1/32 | 5 to 8 | 1/16 | 1/8 | |||||||||

| 3 TO 3-1/2 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 10 to 12 | 3/32 | 3/16 | |

| 4 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 14 to 16 | 3/32 | 1/4 | |

| 5 TO 8 | +1/32 | ±1/16 | ±1/16 | ±1/16 | ±1/4 | ±1/4 | ±1/4 | ±1/32 | 18 to 24 | 1/8 | 3/8 | |

| -1/16 | ||||||||||||

| 10 TO 18 | +1/16 | ±1/8 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | All dimensions are in inches | |||

| -1/8 | ||||||||||||

| 20 TO 24 | +1/4 | ±3/32 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | ||||

| -3/32 | ||||||||||||

Chemical Structure

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Inconel 600 Pipe Fittings Across the Globe

Bolivia, Egypt, Tibet, New Zealand, Yemen, Mexico, Kuwait, Serbia, Russia, Sweden, Bangladesh, Bhutan, Saudi Arabia, Finland, Australia, Bahrain, Angola, Portugal, Algiera, Kazakhstan, Thailand, Canada, Croatia, Hungary, Nepal, Macau, France, Poland, Vietnam, Libya, Norway, Argentina, Oman, Hong Kong, Turkey, Iraq, India, Brazil, Israel, Ghana, Iran, Philippines, Puerto Rico, Belgium, Jordan, China, Tunisia, Gabon, Sri Lanka, Greece, Japan, Colombia, Lahore, Italy, Spain, United Kingdom, United Arab Emirates, Netherlands, Zimbabwe, Malaysia, Algeria, Romania, Pakistan, South Korea, Kenya, Morocco, Costa Rica, Taiwan, Austria, Lithuania, Nigeria, Ireland, Qatar, Ukraine, Denmark, South Africa, Slovakia, Mongolia, Ecuador, Singapore, Czech Republic, Germany, Peru, Gambia, Bulgaria, Venezuela, Afghanistan, Indonesia, Chile, Namibia, United States, Lebanon, Trinidad & Tobago, Belarus, columbia, Azerbaijan, Estonia, Switzerland.

Domestic Supply Inconel 600 Pipe Fittings

Noida, Pimpri-Chinchwad, Kolkata, Jaipur, Nashik, New Delhi, Chandigarh, Nagpur, Gurgaon, Visakhapatnam, Kanpur, Rajkot, Hyderabad, Howrah, Ranchi, Navi Mumbai, Pune, Thiruvananthapuram, Ernakulam , Secunderabad, Haryana, Indore, Ludhiana, Jamshedpur, Bengaluru, Thane, mumbai, Bhopal, Faridabad, Ahmedabad, Chennai, Surat.

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004