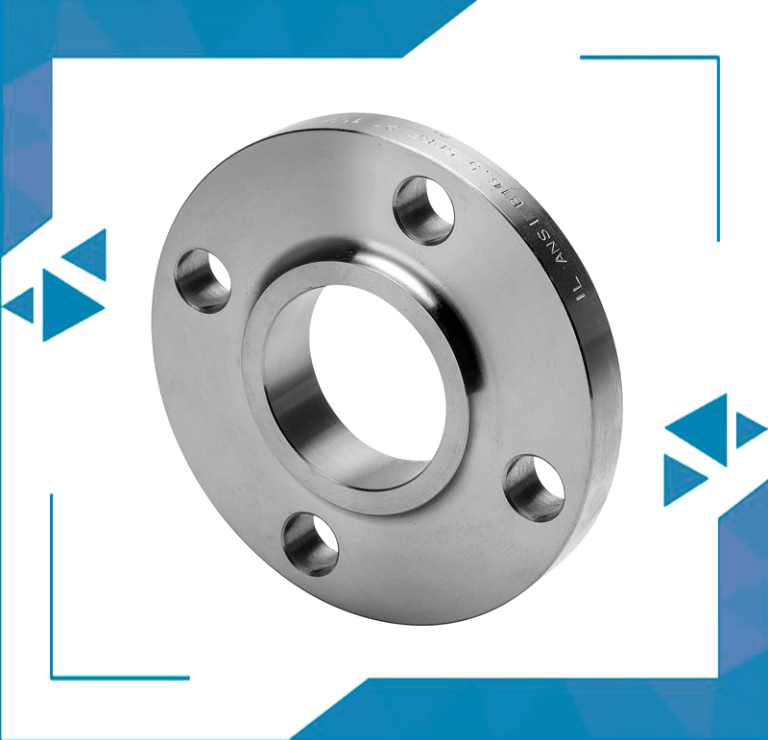

Super Duplex Steel S32760 Flanges Manufacturer

Home / Duplex Steel Flanges / Super Duplex Steel S32760 Flanges

Global Steel is a well-known manufacturer and supplier of Super Duplex S32760 flanges. Due to our considerable expertise and experience in the business, we are able to deliver our products at competitive rates as one of India’s most reputable stockholders of Super Duplex S32760 flanges.

Super Duplex S32760 flanges are one of the most popular super duplex grade flanges on the market. In comparison to Super Duplex S32750, Super Duplex S32760 is duplex stainless steel that has added Tungsten and copper for use in harsh chloride-containing environments. It combines great mechanical strength with excellent resistance to localized corrosion and stress corrosion cracking.

Table Of content

- About Super Duplex Steel S32760 Flanges

- Specification List of SDSS S32760 Flanges

- Equivalent Grades Of Super Duplex Steel S32760 Flanges

- Manufacturing Standards of ASTM A182 S32760 Flanges

- Different Types of Super Duplex Steel S32760 Flanges

- Available Stock of SDSS S32760 Flanges

- SDSS S32760 Flanges Weight Chart

- Super Duplex Steel S32760 Pipe Flange Dimensions

- S32760 Super Duplex Steel Flanges Pressure Rating

- Chemical Structure of Super Duplex Steel S32760 Flanges

- Mechanical Properties of SDSS S32760 Flanges

- We Serve Application Industry

- We Export Super Duplex Steel S32760 Flanges Across the Globe

- Domestic Supply Super Duplex Steel S32760 Flanges

The corrosion resistance and strength of Super Duplex S32760 flanges are exceptional. They are appropriate for use in chemical plants, seawater desalination facilities, and other harsh settings. Super Duplex S32760 is well-known for its high impact strength, with no ductile-brittle transition and just a minor decrease in impact energy as temperature drops. Super Duplex S32760 has a somewhat lower impact strength even when welded. In sour-gas conditions, it also possesses exceptional resistance to sulfide-stress corrosion cracking.

Various welding procedures, such as shielded metal arc welding, TIG welding, and plasma welding, are applicable in the same way as with normal austenitic stainless steels. For Super Duplex S32760 flanges welding electrodes are recommended. It is not necessary to pre-heat or heat afterward. To avoid the production of intermetallic compounds during welding, the interpass temperature should not exceed 100°C.

Due to its properties, Super Duplex S32760 flanges are used in a wide range of applications such as Desalination plants, Seawater systems, Heat exchangers, Subsea pipework systems, and Flue gas desulphurization(FGD) plants, Centrifuges and agitators, Valves and pumps, Storage tanks and pressure vessels, etc.

What are the benefits of using Super Duplex Steel S32760 Flanges?

Super Duplex Steel S32760 Flanges offer several benefits, including increased strength and resistance to corrosion, improved durability, and resistance to stress corrosion cracking, pitting, and crevice corrosion. These flanges are ideal for use in harsh environments, such as in the oil and gas, petrochemical, chemical processing, offshore engineering industries, and seawater applications. The high strength and corrosion resistance of Super Duplex Steel S32760 make it a popular choice for use in a wide range of demanding applications.

Which industries use Super Duplex Steel S32760 Flanges?

Super Duplex Steel S32760 Flanges are widely used in several industries that require high strength and corrosion resistance. These industries include oil and gas, petrochemical, chemical processing, offshore engineering, and seawater applications. The unique properties of Super Duplex Steel S32760 make it an ideal choice for use in harsh environments where high strength and resistance to corrosion are critical. Additionally, Super Duplex Steel S32760 is used in applications that require resistance to stress corrosion cracking, pitting, and crevice corrosion, such as in pipelines, heat exchangers, and pressure vessels.

What is the chemical composition of Super Duplex Steel S32760 Flanges?

Super Duplex Steel S32760 is a high-performance stainless steel alloy with a chemical composition that includes high levels of chromium, molybdenum, and nitrogen, contributing to its high strength and resistance to corrosion. Other elements, such as nickel, iron, and manganese, may also be in smaller amounts. The specific chemical composition can vary slightly depending on the manufacturer. The high levels of chromium provide excellent corrosion resistance, while the molybdenum and nitrogen enhance their strength. The combination of these elements results in a material that is highly resistant to corrosion and has high power, making it ideal for use in harsh environments and demanding applications.

Specification of SDSS S32760 Flanges

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Super Super Duplex S32760 | 1.4501 | S32760 |

Manufacturing Standards

| ASME/ANSI B16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B16.36 | Orifice Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Different Types

Super Duplex Steel S32760 Slip On Flanges

Super Duplex Steel S32760 Blind Flanges

Super Duplex Steel S32760 Socket Weld Flanges

Super Duplex Steel S32760 Weld Neck Flanges

Super Duplex Steel S32760 Reducing Flanges

Super Duplex Steel S32760 Orifice Flanges

Contact us to get a quick quote for your requirement.

We offer These Super Duplex Steel S32760 Flanges as per DIN, ASTM, ASME, BS, EN, JIS or ANSI Standard.

Available Stock

- UNS S32760 Male & Female Flanges

- Super Duplex Stainless Steel S32760 RTJ Flanges

- Type S32760 SDSS Industrial Forged Flanges

- Grade S32760 Super Duplex Steel Flanges

- UNS S32760 Super Duplex Steel Lap Joint Flanges

- S32760 Super Duplex Steel Flanges

- Super Duplex Steel S32760 Plate Flange

- Super Duplex Steel S32760 Tongue Flanges

- Super Duplex Steel S32760 PN 10 Flange

- S32760 SDSS Flanges

- SDSS S32760 Groove Flanges

- ASME B16.47 Super Duplex S32760 Spades Ring Spacers Flanges

- S32760 Super Duplex Steel Nipoflange

- S32760 Super Duplex Stainless Steel Pipe Flange

- ANSI B16.5 Super Duplex Steel S32760 Expander Flanges

- ASTM A182 S32760 Super Duplex Steel Flanges

- Super Duplex S32760 NPT / BSP Thread Flanges

- S32760 Super Duplex Stainless Steel Weldo Flanges

- Super Duplex Stainless Steel S32760 Flanges

- Super Duplex Steel S32760 Long Welding Neck Flange

- SDSS 1.4501 1500 LBS Flanges

- SDSS S32760 Lapped Joint Flanges

- Super Duplex Steel S32760 Flanges

- Super Duplex Steel S32760 Screwed Flanges

- Super Duplex Steel S32760 Nipo Flanges

- SDSS S32760 Spectacle Blind Flanges

- S32760 Super Duplex Steel 150 LBS Threaded Flanges

- Super Duplex Steel S32760 Spades Ring Spacers Flanges

- Super Duplex Steel S32760 British Standard Table D Pipe Flanges

- Super Duplex Steel S32760 DIN Flanges

- ANSI / ASME B16.5 SDSS S32760 Forged Flanges

- Super Duplex Steel S32760 BS Standard Table E

- SDSS S32760 Flat Face Flanges

Weight Chart

15mm (1/2″) Super Duplex Steel S32760 Flanges Weight Chart

Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Chemical Structure

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32760 | 7.8 | 0.281 | 1350 | 2460 |

We Serve Application Industry

Application Industry

ANSI / ASME 16.5, 16.48, 16.47 Flanges applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Super Duplex Steel S32760 Flanges Across the Globe

Domestic Supply Super Duplex Steel S32760 Flanges

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Duplex / Super Steel Pipe Fittings

- Duplex / Super Duplex Steel Forged Fittings

- Duplex / Super Duplex Steel Flanges

- Duplex / Super Duplex Steel Fasteners

- Duplex / Super Duplex Steel Olets

- Duplex / Super Duplex Steel Instrumentation Accessories

- Duplex / Super Duplex Steel Instrumentation Fittings

- Duplex / Super Duplex Steel Valves

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004