Inconel 617 Instrumentation Fittings Manufacturer

Home / Inconel Instrumentation Fittings / Inconel 617 Instrumentation Fittings

Global Steel is a prominent supplier of Inconel 617 Instrumental fittings. We ensure top-quality, customizable products at the best prices in the industry. All Inconel 617 Instrumental fittings can be customized according to the needs of the buyer.

Inconel 617 Instrumental fittings are built of an alloy which includes nickel, chromium, cobalt, and molybdenum in its alloy. Inconel 617 Instrumental fittings have excellent Creep and oxidation resistance. They can be used in severe temperatures as well as under mechanical strain. They are available in a variety of sizes and dimensions, which can be customized, and contain a variety of elements that can be used in many ways to achieve the desired result. They’re perfect for situations that require temperatures higher than 1000 degrees Fahrenheit.

Table Of content

- About Inconel 617 Instrumentation Fittings

- Specification List of Inconel 617 Instrumentation Fittings

- Equivalent Grades Of Inconel 617 Instrumentation Fittings

- Different Types of Inconel 617 Instrumentation Fittings

- Available Stock of Inconel 617 Instrumentation Fittings

- Inconel 617 Instrumentation Fittings Dimensions

- Chemical Structure of Inconel 617 Instrumentation Fittings

- Mechanical Properties of Inconel 617 Instrumentation Fittings

- We Serve Application Industry

- We Export Inconel 617 Instrumentation Fittings Across the Globe

- Domestic Supply Inconel 617 Instrumentation Fittings

Inconel 617 Instrumental fittings can be made and welded using normal processes and are resistant to several kinds of corrosive conditions. Due to the high content of nickel and chromium present in its alloy, Inconel 617 Instrumental fittings can survive a number of reducing and oxidizing environments. Aluminum, in conjunction with chromium, gives outstanding oxidation resistance at high temperatures. Solid-solution strength is aided by cobalt and molybdenum. Inconel 617 Instrumental fittings exhibit exceptional creep-rupture strength even at temperatures of 1800 degrees Fahrenheit and higher. This feature, combined with the Inconel 617 Instrumental fittings’ resistance to oxidizing and carburizing environments, makes it appropriate for use in applications involving high-stress, long-term use in exceeding temperatures.

They’re employed in fossil-fuel and nuclear power plant components, among many other applications.

Specification of Inconel 617 Instrumentation Fittings

| Imperial Size | 1/2″ to 2″ |

| Size | 1/16”OD to 2”OD, 2mm OD to 50mm OD |

| Thread | NPT, BSP, BSPT, UNF, ISO, SAE, MS, AN, weld ends etc. |

| Pressure Rating | 6000PSI for Stainless Steel, 300/1000/3000PSI for Brass |

| Temperature Ratings | Up to 1000°F (537°C) |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Our service |

|

| Test Certificates |

|

| Production Technique | Forged/ Heat treated and machined. |

Equivalent Grades

| STANDARD | UNS | WNR. |

| Inconel 617 | N06617 | 2.4663 |

Different Types

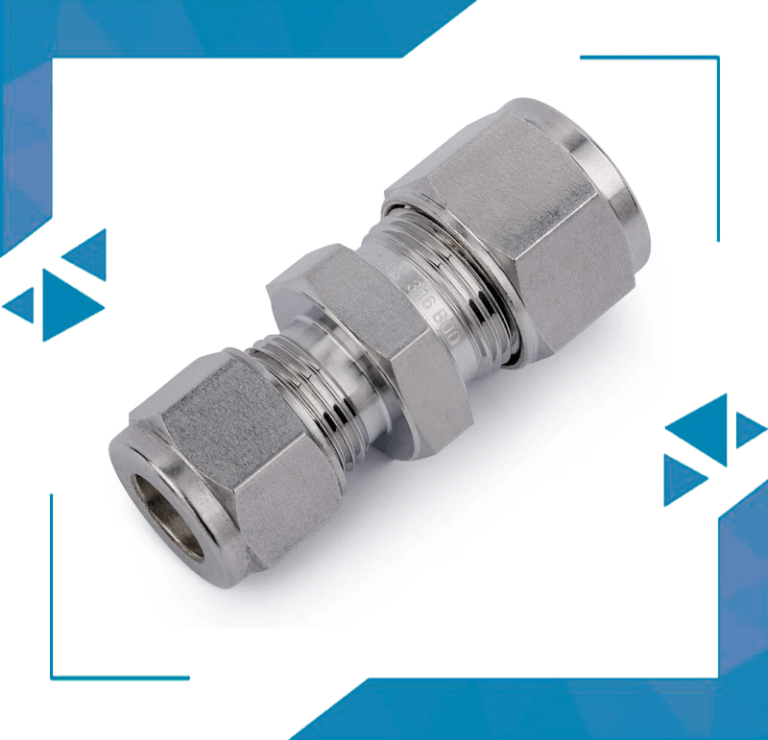

Inconel 617 Instrumentation Union

Inconel 617 Instrumentation Elbow

Inconel 617 Instrumentation Tee

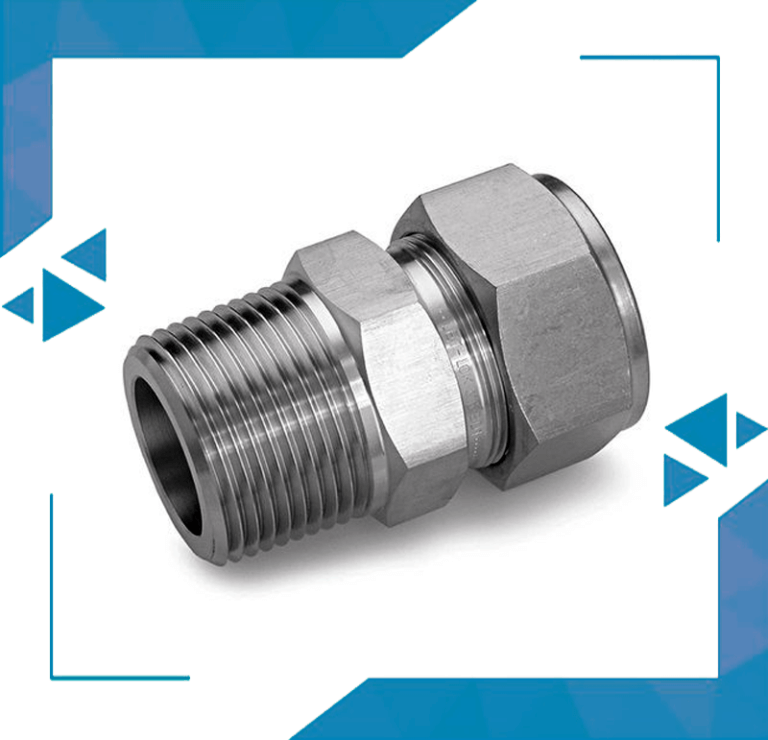

Inconel 617 Instrumentation Connector

Inconel 617 Instrumentation Reducer

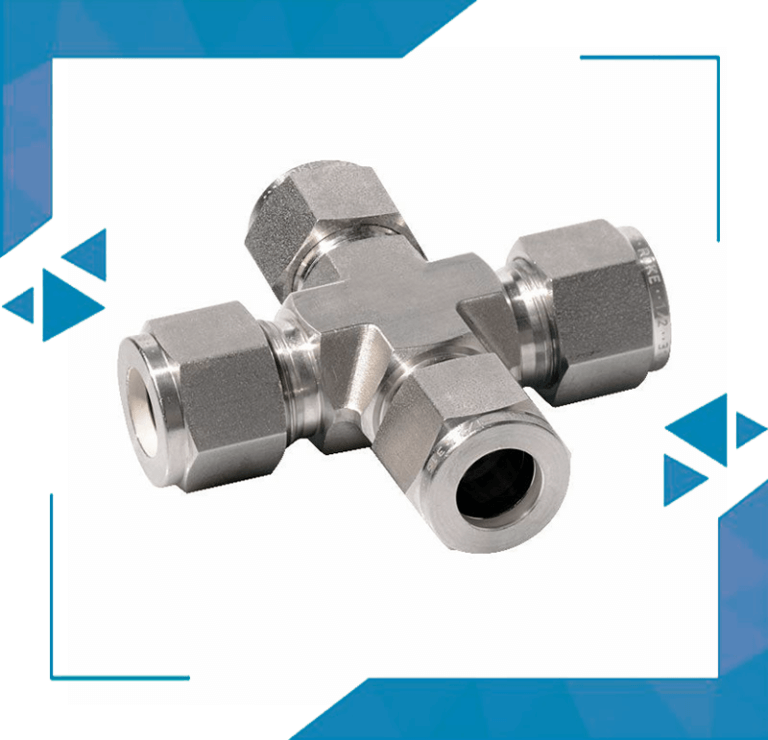

Inconel 617 Instrumentation Cross

Contact us to get a quick quote for your requirement.

We offer These Inconel 617 Instrumentation Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Alloy 617 Reducer Union-RU

- Grade 617 Inconel Union Elbow-UE

- UNS N06617 Instrumentation Fittings

- Alloy 617 BSPP Plugs

- Inconel 617 Instrumentation Fittings

- Inconel Alloy 617 45° Male Elbow – ME

- 617 Inconel Bulk Head Female Connector-BFC

- Alloy 617 Bulk Head Reducer BR

- Inconel® Alloy 617 Union Cross-UC

- Inconel N06617 Instrumentation Fittings

- Inconel Gr 617 Instrumentation Fittings

- Inconel 617 Nut

- 617 Inconel Instrumentation Fittings

- Inconel Alloy 617 Female Elbow-FE

- Alloy 2.4663 Male Elbow – ME

- Inconel 617 Male Stud Coupling Connector

- Inconel 617 Coupling Reducer

- 617 Inconel Alloy Female Connector-FC

- 617 Inconel Alloy Gauge Adaptor

- Inconel Alloy 617 Instrumentation Tube Fittings

- Inconel 617 Male Branch Tee-MBT

- Inconel 617 Female Branch Tee-FBT

- Inconel Alloy 617 Male Run Tee-MRT

- Inconel 617 Instrument Female Run Tee-FRT

- UNS N06617 Inconel Union-U

- Alloy 617 Instrumentation Fittings

- Type 617 Inconel Industrial Instrumentation Fittings

- Inconel® Alloy 617 Bulk Head Union-BU

- 617 Inconel Alloy Instrumentation Fittings

- Alloy 2.4663 Compression Tube Fittings

- Inconel 617 Male Pipe Weld Connector-MPWC

- 617 Inconel Male Branch Tee

- Alloy 617 Female Branch Tee

- Inconel Alloy 617 Plug (Port Ends)-TP

- Inconel 617 Male ElboW

- Inconel 617 Hose Nipple BSP

- Inconel 617 Back Ferrule-BF

- Inconel Alloy 617 Male Run Tee

- Inconel 617 Adaptor

- Inconel 617 Coupling Socket

- Inconel Alloy 617 Female Connector

- Inconel® Alloy 617 Instrumentation Tube Fittings

- Inconel Alloy 617 Female Elbow

- Inconel® Alloy 617 Female Adapter-FA

- Inconel 2.4663 Tube Socket Weld Union-TSWU

- Alloy 617 Bulk Head Male Connector

- 617 Inconel Male Pipe Weld Elbow-MPWE

- Inconel 617 Instrumentation Tube Fittings

- 617 Inconel Hex Long Nipple

- Alloy 617 Front Ferrule-FF

- 617 Inconel Reducing Adaptor

- Inconel 617 Tube Socket Weld Elbow-TSWE

- Inconel 617 Male Plug

- Inconel 617 Instrumentation Reducer-R

- Inconel Grade 617 Reducer Union

- Alloy 617 Male Adapter-MA

- Inconel Alloy 617 Female Run Tee

- Inconel 617 Port Connector-PC

Dimensions

| METRIC RANGE | Dimension in mm | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1″ | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1″ | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1″ | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

Chemical Structure

| Grade | C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| Inconel 617 | 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

We Serve Application Industry

Application Industry

Instrumentation Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Inconel 617 Instrumentation Fittings Across the Globe

Mongolia, Taiwan, Chile, Azerbaijan, Indonesia, Tibet, Romania, Australia, Portugal, Sri Lanka, Tunisia, Bulgaria, Nigeria, Serbia, Yemen, Malaysia, Libya, South Africa, Argentina, United States, Hong Kong, Jordan, columbia, Trinidad & Tobago, Vietnam, Slovakia, France, Bolivia, China, Kuwait, United Kingdom, Hungary, Nepal, Italy, Oman, Poland, Switzerland, New Zealand, Peru, Japan, Spain, Greece, Estonia, Belarus, Turkey, Ghana, Lahore, Singapore, Kazakhstan, Iran, United Arab Emirates, Costa Rica, Puerto Rico, Algeria, Bahrain, Gambia, Macau, Qatar, Lithuania, Zimbabwe, South Korea, Norway, Croatia, Ukraine, India, Ecuador, Morocco, Canada, Kenya, Egypt, Thailand, Saudi Arabia, Algiera, Germany, Denmark, Angola, Netherlands, Brazil, Mexico, Czech Republic, Ireland, Venezuela, Colombia, Philippines, Lebanon, Finland, Afghanistan, Bhutan, Israel, Belgium, Russia, Bangladesh, Pakistan, Iraq, Austria, Gabon, Sweden, Namibia.

Domestic Supply Inconel 617 Instrumentation Fittings

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004