Inconel 600 Valves Manufacturer

Home / Inconel Valves / Inconel 600 Valves

Global Steel manufactures its goods according to worldwide production standards, ensuring consistent quality across the board and making things using top-class machinery that ensures durability. We’ve combined our expert labor and years of knowledge to create goods with incredible usability. We develop a variety of items that are tailored to market demands, and produce and sell a wide range of Inconel Alloy 600 Valves.

Table Of content

- About Inconel 600 Valves

- Specification List of Inconel 600 Valves

- Equivalent Grades Of Inconel 600 Valves

- Different Types of Inconel 600 Valves

- Available Stock of Inconel 600 Valves

- Inconel 600 Valves Pressure Rating

- Inconel 600 Neddle Valves Dimension Standards

- Chemical Structure of Inconel 600 Valves

- Mechanical Properties of Inconel 600 Valves

- We Serve Application Industry

- We Export Inconel 600 Valves Across the Globe

- Domestic Supply Inconel 600 Valves

The Inconel 600 Valve can suit the needs of automobile engineers who require a valve that can withstand heat better than stainless steel. Nickel, Molybdenum, and Chromium alloys are used to make Inconel 600 Valves, which also contain resistant alloying elements. In situations where high temperature and resistance to corrosion are required, Inconel 600 valves are designed and fabricated. It possesses nonmagnetic qualities that allow it to combine high strength with good weldability at a variety of temperatures. Inconel UNS N06600 Valve is a nickel-chromium alloy that is resistant to high temperatures and corrosion. Many applications that require cryogenic temperatures employ Inconel UNS N06600 Valve. Alloy 600 Valve is a high-strength alloy with excellent heat resistance. Aqueous corrosion is impenetrable to 600 Inconel Valves. Alloy 600 Valves are widely utilized in distilleries, steel mills, water treatment facilities, refineries, paper mills, and pharmaceuticals for analytical instruments, process systems, and research applications. Apart from that, Inconel 600 Valves is known to be resistant to alkaline solutions as well as chloride-ion stress corrosion cracking. Chemical, food processing, gas turbine components heat-treating sector, and aerospace are just a few of the industries that use these Valves. Water treatment plants, offshore platforms, petrochemical plants, refineries, and shipbuilding are just a few of the applications of Alloy 600 Valves. Check valves, needle valves, non-return valves, bleed valves, and double blocks are some valves available.

What are the considerations for selecting Inconel 600 Valves?

When selecting Inconel 600 valves, there are a few things to remember. First, determine the temperature range and working pressure of the process. This will help narrow the selection to ensure the valves can handle these conditions. Additionally, consider corrosive exposure as any environment with high concentrations of acids or other reactive agents requires unique materials to resist corrosion. Lastly, consider specialist requirements like cryogenic temperatures or insulation needs that must be considered before making a final choice. Ultimately selecting the right Inconel 600 valve is essential for ensuring optimal performance and operation of a system.

What is the maintenance required for Inconel 600 Valves?

The primary maintenance requirement for Inconel 600 valves is to remain properly lubricated. The lubricant used should be explicitly designed for this type of valve. It should be applied once per week or at least once a month, depending on the environment and operating conditions. Additionally, any exposed parts of the valves themselves should be checked for corrosion or signs of wear regularly, with corroded components replaced if necessary. Otherwise, occasional cleaning can help ensure that Inconel 600 valves remain in working condition and provide their optimum performance.

Specification of Inconel 600 Valves

| Standards | API 598 / BS EN 12266-1, ASME B 16.10, Sizes available on request API 600/BS1414, 1/8 to 1”, ASME B 16.34, ASME B 16.5, ASME B16.25 |

| Sizes | Sizes available on Request, 1/8 to 1”, 1/2′ TO 14” |

| Working Pressure | Valves are also available which could handle higher pressure, Up to 6000 PSIG |

| End Connection | BSPT, Male and Female NPT, Male to Female, Socket Weld (SW) or Dual Ferrule Tube Connections, Female to Female |

| Temperature Ratings | (232C)/Grafoil 700 F(371C), PTFE 450F |

| Pressure Rating | 150#, 300#, 600#, 800#, 1500# |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Ends | Flange Ends, Screwed Ends,Socket Weld Ends |

| Type | Ball Valves, Globe Valves, Check Valves, Needle Valves, Butterfly Valves |

| Temperature Rating | (232C)/Grafoil 700 F(371C),PTFE 450F |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Different Types

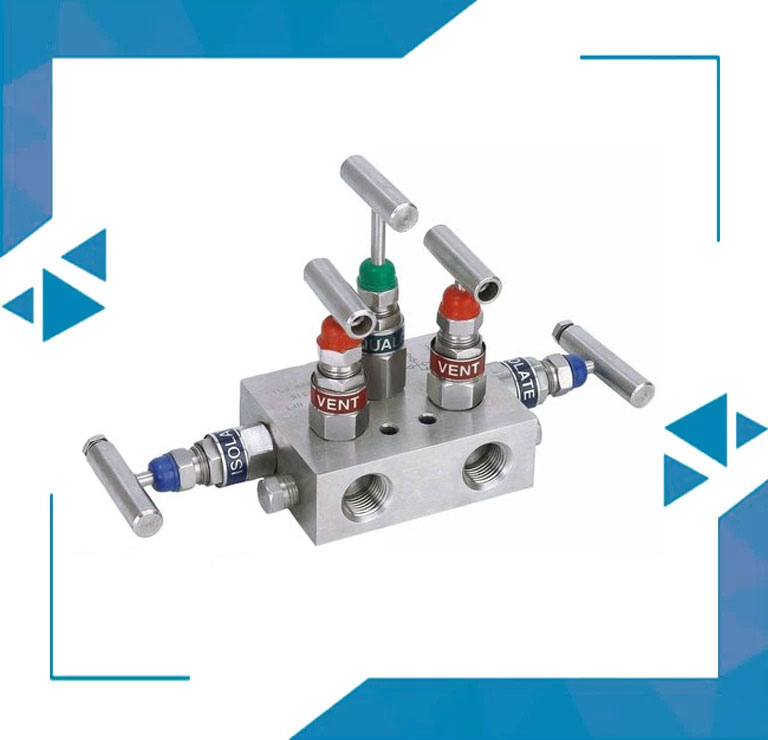

Inconel 600 Manifold Valves

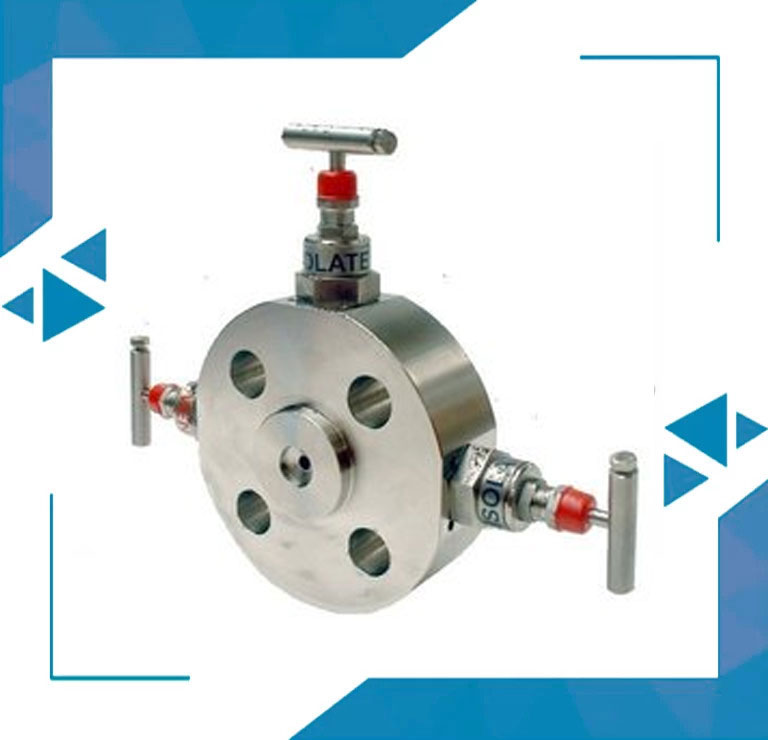

Inconel 600 Monoflange Manifold Valves

Inconel 600 Double Block & Bleed Valves

Inconel 600 Needle Valves

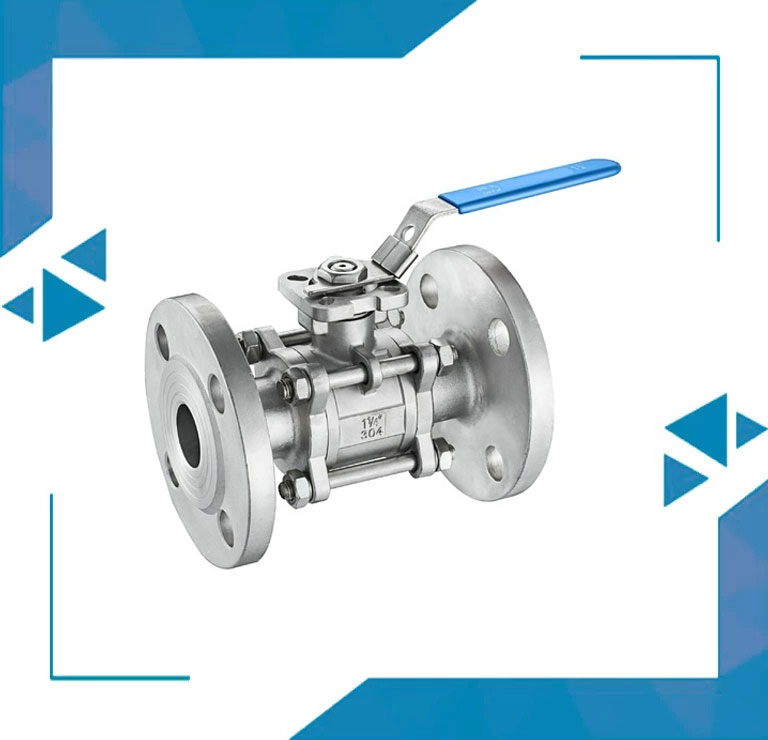

Inconel 600 Ball Valves

Inconel 600 Check Valves (nrv) & Piston

Contact us to get a quick quote for your requirement.

We offer These Inconel 600 Valves as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Inconel 600 Block Bleed Valve

- Inconel Alloy 600 Manifold Check Valve

- Alloy N06600 Instrumentation Check Valve

- Inconel Alloy 3 Way Needle Valve

- Inconel 600 Monoflange Valves

- Alloy 600 Forged Integral Bonnet Angle Type Needle Valves

- 600 Inconel Alloy Manifold Valves

- Inconel 600 Mini Needle Valve

- Alloy 600 Instrumentation Needle Valve

- Inconel Alloy 600 Valves

- Alloy 600 Hydraulic Ball Valve

- Inconel 600 Panel Mounted Ball Valve

- UNS N06600 Threaded Butterfly Valves

- 600 Inconel Forged Steel Valves

- Inconel® Alloy 600 Needle Valve

- Inconel Alloy 2.4816 High Pressure Ball Valves

- Nickel Alloy 600 Integral-Bonnet Needle Valves

- Alloy 600 Industrial Valves

- Inconel 2.4816 Panel Mounted Needle Valve

- Inconel 600 Instrumentation Non Return Valve

- Inconel® Alloy 600 Pannel Mounting Ball Valve

- Inconel N06600 4 Way Ball Valve

- Inconel 600 Ball Valve

- Inconel 600 Ball Valve Threaded

- Inconel Alloy N06600 Valves

- Inconel 600 Hydraulic Ball Valve

- Alloy 600 Manifold Check Valve

- Inconel Alloy 600 Bleed and Purge Valves

- Inconel 600 2 Way Ball Valves

- Alloy 600 3-way Flange Ball Valves

- Inconel 600 Monoflange Manifold Valves

- Inconel 2.4816 High Pressure Ball Valve

- Inconel 600 5 Way Manifold Valve

- Inconel® Alloy 600 Valves

- UNS N06600 Non Return Valve

- 600 Inconel Forged-Body Needle Valves

- Inconel 600 Double Block & Bleed Valves

- Alloy 600 Panel Mounted Ball Valve

- Inconel Alloy 2.4816 Female X Female Check Valve

- Nickel Alloy 600 Valves

- Inconel 600 High Pressure Needle Valve

- 600 Inconel Valves

- Inconel 600 Instrumentation Ball Valves

- 600 Inconel Instrumentation Check Valve

- Inconel N06600 3 PCS Ball Valve

- Inconel 600 Valves

- Inconel 600 Pressure Reducing Valve

- Inconel Alloy 600 Instrument Solenoid Valve

Pressure Rating

| Temp. °F | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

|---|---|---|---|---|---|---|---|

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 [1] | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 [1] | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 [1] | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 [1] | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 [1] | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 [1] | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 [1] | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 [1] | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 [1] | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 [1] | 25 | 35 | 55 | 80 | 135 | 230 |

Dimension Standards

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Chemical Structure

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Inconel 600 Valves Across the Globe

Domestic Supply Inconel 600 Valves

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004