Hastelloy C276 Valves Manufacturer

Home / Hastelloy Valves / Hastelloy C276 Valves

Hastelloy C276 Valves are valves made from the Hastelloy C276 alloy. This nickel-based alloy has outstanding corrosion resistance to highly oxidizing and reducing environments. UNS N10276 Valves are designed to perform in harsh environments where traditional valve materials like stainless steel, carbon steel & bronze would not hold up. The valves are made of two-piece or three-piece body construction, which means the valve body is in two or three parts bolted together for easy maintenance or repair.

The primary benefit of the Hastelloy C276 Valves is its excellent corrosion resistance. It can withstand pitting, crevice corrosion, and stress corrosion cracking in various environments. This alloy can handle various chemicals, including chlorine, sulfuric acid, and hydrochloric acid, making it ideal for valve construction. Alloy C276 Valves high tensile strength, flexibility, and durability are other benefits.

Table Of content

- About Hastelloy C276 Valves

- Specification List of Hastelloy C276 Valves

- Equivalent Grades Of Hastelloy C276 Valves

- Different Types of Hastelloy C276 Valves

- Available Stock of Hastelloy C276 Valves

- Hastelloy C276 Valves Pressure Rating

- Hastelloy C276 Neddle Valves Dimension Standards

- Chemical Structure of Hastelloy C276 Valves

- Mechanical Properties of Hastelloy C276 Valves

- We Serve Application Industry

- We Export Hastelloy C276 Valves Across the Globe

- Domestic Supply Hastelloy C276 Valves

JIS NW 0276 Valves are used in harsh environments where corrosion is a concern. They are commonly used in chemical processing, wastewater treatment, and oil and gas refineries. These valves are used in piping systems to regulate and control fluid flow. They are found in many applications, such as pharmaceuticals, food processing, and power generation.

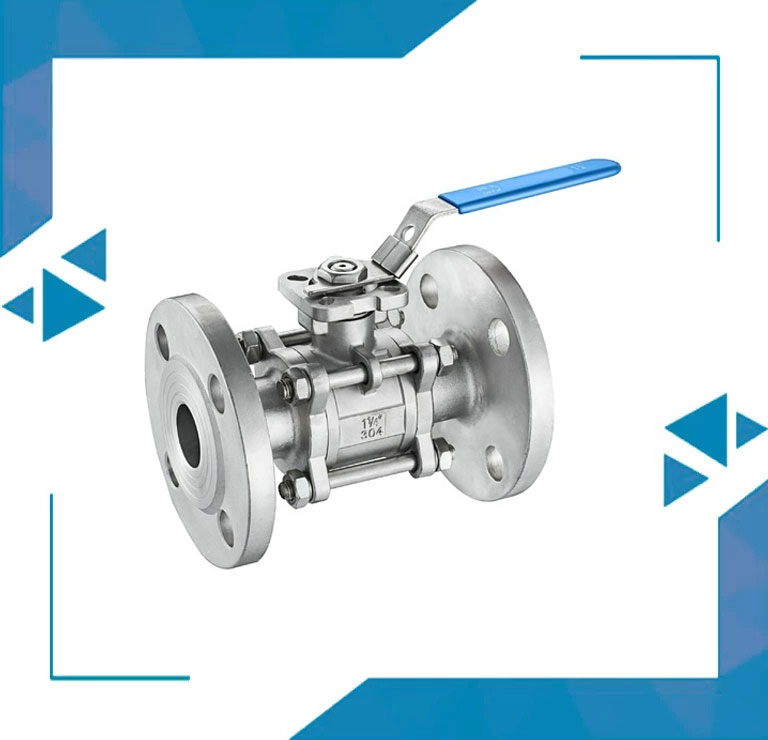

Hastelloy C276 Ball Valves have excellent mechanical properties, including high strength, flexibility, and toughness. They maintain their mechanical traits in high-temperature environments, making them an ideal valve material. Alloy 2.4819 Needle Valves has a high resistance to oxidation and corrosion at higher temperatures. The valves do not react to chloride and sulfide ion stress corrosion cracking, pitting, and crevice corrosion. They are also effective against sulfuric acid, phosphoric acid, and hydrochloric acid. The high-quality hastelloy products we provide at Global Steel include Hastelloy Valves, Hastelloy C22 Valves and more.

C276 Hastelloy Valves are a reliable solution for corrosive environments. Their high tensile strength, flexibility, and durability make them an ideal material for valve construction. The valves are often used in the chemical processing, wastewater treatment, and oil and gas industries. Hastelloy 2.4819 Valves have outstanding corrosion resistance in reducing and oxidizing environments and maintain their properties at high temperatures. We provide an extensive range of products, such as Monel 400 Flanges, Stainless Steel 904L Pipe Fittings and more.

In which industries are Hastelloy C276 Valves commonly used?

Hastelloy C276 Valves are commonly used in chemical processing, oil and gas, petrochemical, pharmaceutical, pulp and paper, wastewater treatment & power generation. They are suitable for applications involving corrosive fluids and gases.

What types of Hastelloy C276 Valves are available?

Hastelloy C276 Valves are available in various types, including ball, gate, globe, check, and butterfly valves. Each type offers specific functionality and is designed for different flow control applications, providing options for diverse industrial requirements.

Can Hastelloy C276 Valves be used in high-pressure and high-temperature applications?

Yes, Hastelloy C276 Valves are designed to withstand high-pressure & high-temperature environments. They exhibit good mechanical strength and retain corrosion resistance even at elevated temperatures, making them suitable for demanding industrial applications.

Specification of Hastelloy C276 Valves

| Standards | API 598 / BS EN 12266-1, ASME B 16.10, Sizes available on request API 600/BS1414, 1/8 to 1”, ASME B 16.34, ASME B 16.5, ASME B16.25 |

| Sizes | Sizes available on Request, 1/8 to 1”, 1/2′ TO 14” |

| Working Pressure | Valves are also available which could handle higher pressure, Up to 6000 PSIG |

| End Connection | BSPT, Male and Female NPT, Male to Female, Socket Weld (SW) or Dual Ferrule Tube Connections, Female to Female |

| Temperature Ratings | (232C)/Grafoil 700 F(371C), PTFE 450F |

| Pressure Rating | 150#, 300#, 600#, 800#, 1500# |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Ends | Flange Ends, Screwed Ends,Socket Weld Ends |

| Type | Ball Valves, Globe Valves, Check Valves, Needle Valves, Butterfly Valves |

| Temperature Rating | (232C)/Grafoil 700 F(371C),PTFE 450F |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C276 | 2.4819 | N10276 | NW 0276 | ХН65МВУ | NiMo16Cr15W | ЭП760 |

Different Types

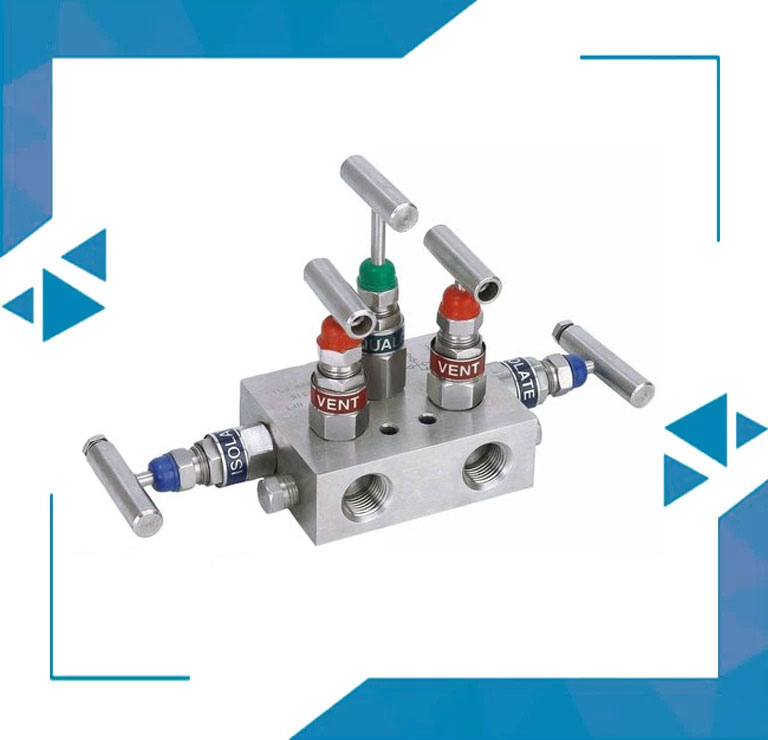

Hastelloy C276 Manifold Valves

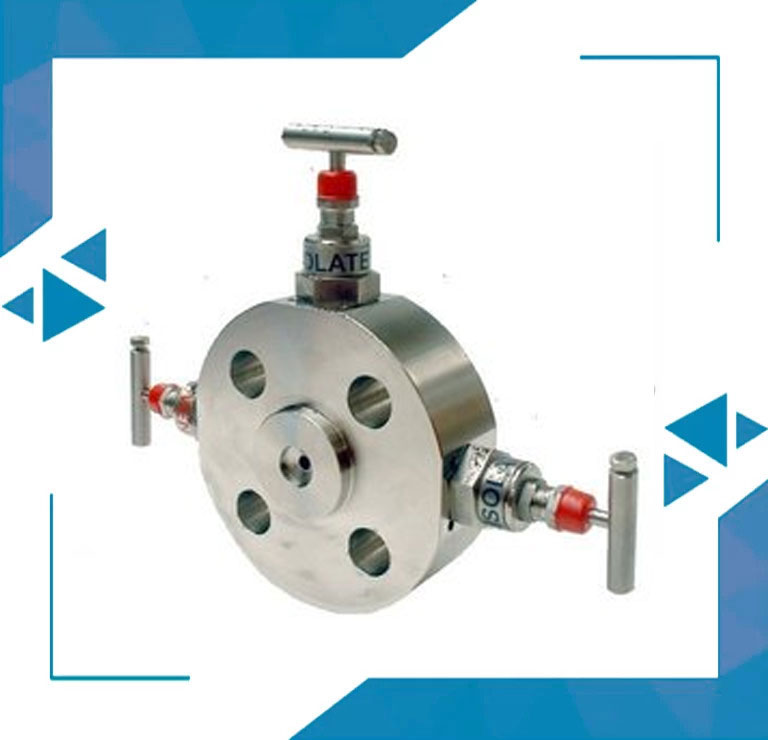

Hastelloy C276 Monoflange Manifold Valves

Hastelloy C276 Double Block & Bleed Valves

Hastelloy C276 Needle Valves

Hastelloy C276 Ball Valves

Hastelloy C276 Check Valves (nrv) & Piston

Contact us to get a quick quote for your requirement.

We offer These Hastelloy C276 Valves as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Hastelloy C276 Mini Needle Valve

- Hastelloy C276 Block Bleed Valve

- C276 Hastelloy Forged Steel Valves

- Hastelloy C276 Instrumentation Non Return Valve

- Hastelloy C276 Ball Valve

- Hastelloy C276 Panel Mounted Ball Valve

- Alloy C276 Instrumentation Needle Valve

- Hastelloy N10276 4 Way Ball Valve

- Hastelloy C276 Monoflange Valves

- Alloy N10276 Instrumentation Check Valve

- Alloy C276 Industrial Valves

- Hastelloy® Alloy C276 Pannel Mounting Ball Valve

- Hastelloy Alloy C276 Manifold Check Valve

- Alloy C276 Forged Integral Bonnet Angle Type Needle Valves

- UNS N10276 Threaded Butterfly Valves

- Hastelloy 2.4819 Panel Mounted Needle Valve

- Hastelloy Alloy 2.4819 High Pressure Ball Valves

- Hastelloy Alloy C276 Bleed and Purge Valves

- Hastelloy C276 Pressure Reducing Valve

- Hastelloy C276 Instrumentation Ball Valves

- Hastelloy C276 Double Block & Bleed Valves

- Hastelloy C276 High Pressure Needle Valve

- Hastelloy C276 NRV Check Valve

- Hastelloy 2.4819 High Pressure Ball Valve

- Hastelloy C276 Monoflange Manifold Valves

- Alloy C276 3-way Flange Ball Valves

- Alloy C276 Manifold Check Valve

- Hastelloy C276 2 Way Ball Valves

- Hastelloy C276 Ball Valve Threaded

- Hastelloy C276 Hydraulic Ball Valve

- C276 Hastelloy Valves

- Hastelloy N10276 3 PCS Ball Valve

- C276 Hastelloy Forged-Body Needle Valves

- Hastelloy Alloy 2.4819 Female X Female Check Valve

Pressure Rating

| Temp. °F | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

|---|---|---|---|---|---|---|---|

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 [1] | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 [1] | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 [1] | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 [1] | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 [1] | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 [1] | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 [1] | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 [1] | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 [1] | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 [1] | 25 | 35 | 55 | 80 | 135 | 230 |

Dimension Standards

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Chemical Structure

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Hastelloy C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004