Hastelloy C276 Instrumentation Fittings Manufacturer

Home / Hastelloy Instrumentation Fittings / Hastelloy C276 Instrumentation Fittings

Global Steel is a leading supplier of Hastelloy C276 Instrumentation fittings. We ensure premium quality products at competitive prices. All our products go through a strict quality check with regards to internationally recognized standards.

Table Of content

- About Hastelloy C276 Instrumentation Fittings

- Specification List of Hastelloy C276 Instrumentation Fittings

- Equivalent Grades Of Hastelloy C276 Instrumentation Fittings

- Different Types of Hastelloy C276 Instrumentation Fittings

- Available Stock of Hastelloy C276 Instrumentation Fittings

- Hastelloy C276 Instrumentation Fittings Dimensions

- Chemical Structure of Hastelloy C276 Instrumentation Fittings

- Mechanical Properties of Hastelloy C276 Instrumentation Fittings

- We Serve Application Industry

- We Export Hastelloy C276 Instrumentation Fittings Across the Globe

- Domestic Supply Hastelloy C276 Instrumentation Fittings

Hastelloy C276 Instrumentation fittings are made of a wrought nickel-chromium-molybdenum alloy that is widely considered to be the most corrosion-resistant alloy on the market. Hastelloy C276 is suitable for most chemical process applications in the as-welded state because it resists the formation of grain boundary precipitates in the weld heat-affected zone. Pitting, stress-corrosion cracking, and oxidizing atmospheres up to 1900°F are all resistant to Hastelloy C276 Instrumentation fittings. Instrumentation fittings made of Hastelloy C-276 can tolerate a wide range of chemical conditions.

Hastelloy C-276 Instrumentation fittings are a nickel-chromium-molybdenum alloy with unrivaled corrosion resistance across the board. Ferric and cupric chlorides, hot contaminated mineral acids, solvents, chlorine and chlorine contaminated (both organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, seawater, and brine solutions, and hypochlorite and chlorine dioxide solutions are all particularly resistant to it. Alloy C276 resists the formation of grain boundary precipitates in the weld heat-affected zone in the as-welded condition, making it appropriate for most chemical applications. It is resistant to pitting and stress corrosion cracking.

Hastelloy C276 Instrumentation fittings are used in various applications like Digesters and bleach plants in the paper industry, Components exposed to sour gas, Equipment for flue-gas desulfurization plants, Evaporators, heat exchangers, filters and mixers used in sulfuric acid environments, Sulfuric acid reactors, Organic chloride process equipment, Equipment for processes utilizing halide or acid catalysts.

Specification of Hastelloy C276 Instrumentation Fittings

| Imperial Size | 1/2″ to 2″ |

| Size | 1/16”OD to 2”OD, 2mm OD to 50mm OD |

| Thread | NPT, BSP, BSPT, UNF, ISO, SAE, MS, AN, weld ends etc. |

| Pressure Rating | 6000PSI for Stainless Steel, 300/1000/3000PSI for Brass |

| Temperature Ratings | Up to 1000°F (537°C) |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Our service |

|

| Test Certificates |

|

| Production Technique | Forged/ Heat treated and machined. |

Equivalent Grades

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

Different Types

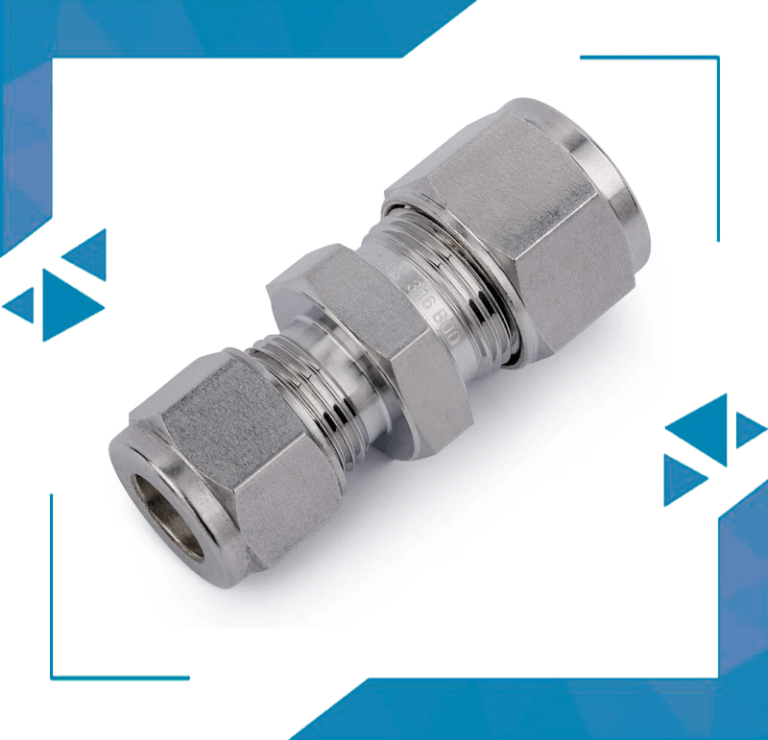

Hastelloy C276 Instrumentation Union

Hastelloy C276 Instrumentation Elbow

Hastelloy C276 Instrumentation Tee

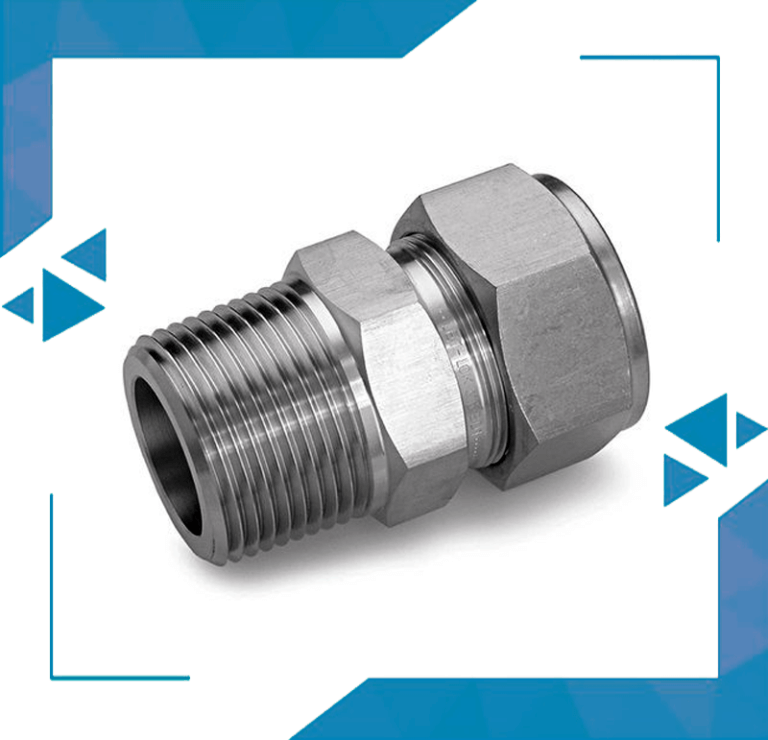

Hastelloy C276 Instrumentation Connector

Hastelloy C276 Instrumentation Reducer

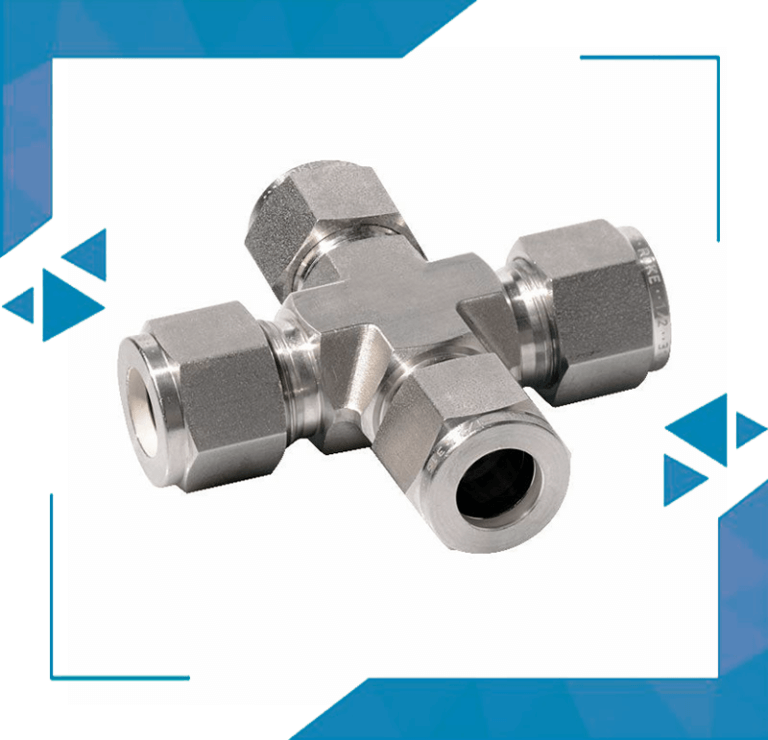

Hastelloy C276 Instrumentation Cross

Contact us to get a quick quote for your requirement.

We offer These Hastelloy C276 Instrumentation Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- C276 Hastelloy Alloy Female Connector-FC

- Hastelloy Alloy C276 Female Elbow-FE

- Hastelloy C276 Female Branch Tee-FBT

- Alloy C276 Reducer Union-RU

- Grade C276 Hastelloy Union Elbow-UE

- C276 Hastelloy Alloy Instrumentation Fittings

- Hastelloy C276 Male Stud Coupling Connector

- Hastelloy C276 Male Branch Tee-MBT

- Hastelloy Alloy C276 45° Male Elbow – ME

- Hastelloy Alloy C276 Male Run Tee-MRT

- Alloy C276 BSPP Plugs

- Type C276 Hastelloy Industrial Instrumentation Fittings

- UNS N10276 Instrumentation Fittings

- Hastelloy C276 Coupling Reducer

- UNS N10276 Hastelloy Union-U

- C276 Hastelloy Alloy Gauge Adaptor

- Hastelloy C276 Tube Socket Weld Elbow-TSWE

- Hastelloy C276 Coupling Socket

- Alloy C276 Bulk Head Male Connector

- Hastelloy® Alloy C276 Female Adapter-FA

- Hastelloy C276 Male Plug

- Hastelloy Alloy C276 Female Run Tee

- Hastelloy Alloy C-276 Female Connector

- Hastelloy C276 Male Pipe Weld Connector-MPWC

- Alloy 2.4819 Compression Tube Fittings

- Hastelloy C276 Port Connector-PC

- Alloy C276 Front Ferrule-FF

- C276 Hastelloy Male Branch Tee

- Hastelloy C276 Adaptor

- Hastelloy C276 Hose Nipple BSP

- Hastelloy C276 Back Ferrule-BF

- Alloy C276 Bulk Head Reducer BR

Dimensions

| METRIC RANGE | Dimension in mm | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 4mMC2 | 4 | 1/8′ | 31.35 | 9.53 | 16.67 | 14.29 | 12 | 12 | 24.21 | 10.72 |

| 4mMC4 | 4 | 1/4′ | 35.72 | 14.29 | 16.67 | 14.29 | 14 | 12 | 29.37 | 15.88 |

| 6mMC2 | 6 | 1/8′ | 33.34 | 9.53 | 18.26 | 15.88 | 14 | 14 | 25.40 | 11.11 |

| 6mMC4 | 6 | 1/4′ | 33.34 | 14.29 | 18.26 | 15.88 | 14 | 14 | 30.16 | 12.70 |

| 6mMC6 | 6 | 3/8′ | 38.89 | 14.29 | 18.26 | 15.88 | 19 | 14 | 30.96 | 13.49 |

| 6mMG8 | 6 | 1/2′ | 44.45 | 19.05 | 18.26 | 15.88 | 22 | 14 | 36.51 | 15.88 |

| 8mMC2 | 8 | 1/8′ | 34.53 | 9.53 | 19.05 | 16.67 | 14 | 17 | 26.59 | 11.51 |

| 8mM04 | 8 | 1/4′ | 39.29 | 14.29 | 19.05 | 16.67 | 14 | 17 | 31.35 | 13.10 |

| 10mM02 | 10 | 1/8′ | 35.72 | 9.53 | 19.84 | 17.46 | 17 | 19 | 27.78 | 11.91 |

| 10mMC4 | 10 | 1/4′ | 40.48 | 14.29 | 19.84 | 17.46 | 17 | 19 | 32.54 | 13.49 |

| 10mMC6 | 10 | 3/8′ | 40.48 | 14.29 | 19.84 | 17.46 | 19 | 19 | 32.54 | 13.49 |

| 10mMC8 | 10 | 1/2′ | 46.04 | 19.05 | 19.84 | 17.46 | 22 | 19 | 38.10 | 15.88 |

| 10mMC12 | 10 | 3/4′ | 46.83 | 19.05 | 19.84 | 17.46 | 27 | 19 | 38.89 | 15.08 |

| 12mMC4 | 12 | 1/4′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC6 | 12 | 3/8′ | 43.66 | 14.29 | 22.23 | 23.02 | 22 | 22 | 33.34 | 11.11 |

| 12mMC8 | 12 | 1/2′ | 48.42 | 19.05 | 22.23 | 23.02 | 22 | 22 | 38.10 | 12.70 |

| 12mM012 | 12 | 3/4′ | 49.21 | 19.05 | 22.23 | 23.02 | 27 | 22 | 38.89 | 11.91 |

| 16mMC6 | 16 | 3/8′ | 44.45 | 14.29 | 22.23 | 24.61 | 24 | 27 | 34.13 | 10.32 |

| 16mMC8 | 16 | 1/2′ | 49.21 | 19.05 | 22.23 | 24.61 | 24 | 27 | 38.89 | 11.91 |

| 16mMC12 | 16 | 3/4′ | 49.21 | 19.05 | 22.23 | 24.61 | 27 | 27 | 38.89 | 10.32 |

| 18mMC8 | 18 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 13.49 |

| 18mMC12 | 18 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 18mMC16 | 18 | 1″ | 56.36 | 23.81 | 22.23 | 24.61 | 36 | 30 | 46.40 | 14.29 |

| 20mMC8 | 20 | 1/2′ | 50.80 | 19.05 | 22.23 | 24.60 | 27 | 30 | 40.48 | 13.49 |

| 20mM012 | 20 | 3/4′ | 50.80 | 19.05 | 22.23 | 24.61 | 27 | 30 | 40.48 | 10.32 |

| 20mM016 | 20 | 1″ | 56.36 | 23.81 | 22.23 | 14.61 | 36 | 30 | 46.04 | 14.39 |

| 25mMC12 | 25 | 3/4′ | 57.15 | 19.05 | 26.19 | 30.96 | 36 | 41 | 45.24 | 11.91 |

| 25mMC16 | 25 | 1″ | 61.91 | 23.81 | 26.19 | 30.96 | 36 | 41 | 50.01 | 13.49 |

| METRIC RANGE | Dimention in Inches | |||||||||

| Part | T | P | L1 | M | C | D | F | G | H | N |

| N0 | mmo/d | Length | Body | Nut | Body | |||||

| 1MC1 | 1/16 | 1/16 | .94 | .38 | .44 | .34 | 5/16 | 5/16 | .78 | .34 |

| 1MC2 | 1/16 | 1/8 | 1.00 | .38 | .44 | .34 | 1/2 | 5/16 | .84 | .41 |

| 2MC1 | 1/8 | 1/16 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC2 | 1/8 | 1/8 | 1.19 | .38 | .63 | .53 | 1/2 | 7/16 | .91 | .41 |

| 2MC4 | 1/8 | 1/4 | 1.41 | .56 | .63 | .53 | 9/16 | 7/16 | 1.13 | .50 |

| 3MC2 | 3/16 | 1/8 | 1.21 | .38 | .63 | .54 | 7/16 | 1/2 | .95 | .43 |

| 3MC4 | 3/16 | 1/4 | 1.42 | .38 | .63 | .54 | 9.16 | 1/2 | 1.16 | .54 |

| 4MC1 | 1/4 | 1/16 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .46 |

| 4MC2 | 1/4 | 1/8 | 1.29 | .56 | .70 | .60 | 1/2 | 9/16 | 1.00 | .45 |

| 4MC4 | 1/4 | 1/4 | 1.50 | .75 | .72 | .63 | 9/16 | 9/16 | 1.19 | .50 |

| 4MC6 | 1/4 | 3/8 | 1.51 | .38 | .70 | .60 | 11/16 | 9/16 | 1.19 | .56 |

| 4MC8 | 1/4 | 1/2 | 1.73 | .56 | .70 | .60 | 7/8 | 9/16 | 1.44 | .67 |

| 5MC2 | 5/16 | 1/8 | 1.34 | .38 | .73 | .64 | 9/16 | 5/8 | 1.05 | .46 |

| 5MC4 | 5/16 | 1/4 | 1.52 | .56 | .73 | .64 | 9/16 | 5/8 | 1.23 | .54 |

| 6MC2 | 3/8 | 1/8 | 1.38 | .56 | .76 | .66 | 5/8 | 11/16 | 1.09 | .48 |

| 6MC4 | 3/8 | 1/4 | 1.57 | .75 | .76 | .66 | 5/8 | 11/16 | 1.28 | .57 |

| 6MC6 | 3/B | 3/8 | 1.57 | .75 | .76 | .66 | 11/16 | 11/16 | 1.28 | .56 |

| 6MC8 | 3/B | 1/2 | 1.79 | .56 | .76 | .66 | 7/8 | 11/16 | 1.50 | .67 |

| 6MC12 | 3/8 | 3/4 | 1.82 | .56 | .76 | .66 | 1-1/16 | 11/16 | 1.53 | .68 |

| 8MC4 | 1/2 | 1/4 | 1.17 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .47 |

| 8MC6 | 1/2 | 3/8 | 1.71 | .75 | .86 | .90 | 13/16 | 7/8 | 1.31 | .46 |

| 8MC8 | 1/2 | 1/2 | 1.90 | .56 | .86 | .90 | 7/8 | 7/8 | 1.50 | .54 |

| 8MC12 | 1/2 | 3/4 | 1.93 | .75 | .86 | .90 | 1-1/16 | 7/8 | 1.53 | .55 |

| 10MC6 | 5/8 | 3/8 | 1.74 | .56 | .86 | .96 | 15/16 | 1 | 1.34 | .43 |

| 10MC8 | 5/8 | 1/2 | 1.93 | .75 | .86 | .96 | 15/16 | 1 | 1.53 | .51 |

| 10MC12 | 5/B | 3/4 | 1.93 | .75 | .86 | .96 | 1-1/16 | 1 | 1.53 | .49 |

| 12MC8 | 3/4 | 1/2 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/8 | 1.59 | .57 |

| 12MC12 | 3/4 | 3/4 | 1.99 | .75 | .86 | .96 | 1-1/16 | 1-1/18 | 1.59 | .55 |

| 12MC16 | 3/4 | 1 | 2.21 | .94 | .86 | .96 | 1-3/16 | 1-1/8 | 1.81 | .68 |

| 16MC12 | 1 | 3/4 | 2.26 | .75 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.78 | .55 |

| 16MC16 | 1 | 1 | 2.45 | .94 | 1.04 | 1.23 | 1-3/8 | 1-1/2 | 1.97 | .65 |

Chemical Structure

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C276 | Balance | 0.01 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

We Serve Application Industry

Application Industry

Instrumentation Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Hastelloy C276 Instrumentation Fittings Across the Globe

Domestic Supply Hastelloy C276 Instrumentation Fittings

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004