Nickel Alloy Valves Manufacturer

Home / Nickel Alloy Valves

Global Steel is a leading and trusted manufacturer and supplier of Nickel Alloy Valves. It offers a wide variety of Nickel Alloy Valves, all of which are designed and manufactured in compliance with international standards. A dedication to continuous design innovation and cutting-edge production techniques allows Global Steel to offer a wide range of Nickel Alloy Valves at an exceptional price. Customers can get the Nickel Alloy Valves customized according to their needs.

Table Of content

- About Nickel Alloy Valves

- Specification List of Nickel Alloy Valves

- Different Types of Nickel Alloy Valves

- Available Stock of Nickel Alloy Valves

- Nickel Alloy Valves Pressure Rating

- Nickel Alloy Neddle Valves Dimension Standards

- We Serve Application Industry

- We Export Nickel Alloy Valves Across the Globe

- Domestic Supply Nickel Alloy Valves

Nickel Alloy Valves are made with a combination of Nickel with another metal. Nickel is a versatile metal that will alloy with almost any other metal. Nickel alloys are alloys in which nickel is the main component. Between nickel and copper, there is complete solid solubility. Many alloy combinations are available due to the wide solubility ranges between iron, chromium, and nickel. Its high adaptability, combined with its exceptional heat and corrosion resistance, has led to its widespread use in a variety of applications, including aircraft gas turbines, power plant steam turbines, and the energy and nuclear power markets. Nickel Alloys are extremely versatile, have increased toughness and corrosion resistance, and also display magnetic properties.

Global Steel uses premium quality materials to manufacture these Nickel Alloy Valves. We are stockholders of a wide variety of Nickel Alloy Valves such as Nickel Alloy Ball Valve, Nickel Alloy Gate Valve, Nickel Alloy Globe Valve, Nickel Alloy Plug Valve, and Nickel Alloy Butterfly Valve. These Valves are used to regulate the flow of liquids, gases, powders, and other materials through pipes or tubes, as well as from tanks or other containers.

How do I size a Nickel Alloy Valve?

Nickel alloy valves are essential for many plumbing, industrial, and chemical applications. Finding the correct size can be challenging, but there are a few simple steps to take. To start, measure the space within the pipeline where the valve will fit. The goal is to ensure that when the valve is installed, it has enough space to move properly without being too tight or loose. Another essential factor to consider is pressure ratings, as wrong pressure ratings can result in unexpected damage to equipment and significant losses for a company. With sufficient information about measurements and pressure requirements, you can select a nickel alloy pipe and fitting with accuracy.

What are some of the best Nickel Alloy Valves in the market?

Nickel alloy valves are highly durable, designed to withstand extreme temperatures, and provide superior seal integrity. Any industrial or commercial building that demands dependable performance and long-term sturdiness should invest in them. Alloys made of nickel combine strength, flexibility at low temperatures, and high-temperature stability. Thanks to their characteristics, Nickel alloys are better than other types of valves in terms of dependability and long-term use. Some of the best nickel alloy valves on the market include lightweight yet strong monel valves, solid hastelloy valves, resistive inconel valves, titanium valves with superior corrosion resistance, and corrosion-resistant duplex stainless steel valves. With these high-quality options, it’s never been easier to invest in reliable structures requiring minimal maintenance or replacement.

How do I select the right Nickel Alloy Valve for my application?

Selecting the suitable nickel alloy valve for your application is vital to ensure you get the best performance from your system. Before making this selection, it is essential to know the exact requirements of your specific application and how much pressure or temperature will be involved. The most suitable alloy valve material should be well-suited to resist erosion and corrosion to maintain its optimal condition over many years. Furthermore, consider looking into the alloy’s purity to make sure it can stand up against any other chemical or physical interactions that may occur in your particular system. It is also highly recommended that you refer to a reliable supplier who can provide recommendations based on their expertise when selecting the best nickel alloy valve for your needs.

Specification of Nickel Alloy Valves

| Standards | API 598 / BS EN 12266-1, ASME B 16.10, Sizes available on request API 600/BS1414, 1/8 to 1”, ASME B 16.34, ASME B 16.5, ASME B16.25 |

| Sizes | Sizes available on Request, 1/8 to 1”, 1/2′ TO 14” |

| Working Pressure | Valves are also available which could handle higher pressure, Up to 6000 PSIG |

| End Connection | BSPT, Male and Female NPT, Male to Female, Socket Weld (SW) or Dual Ferrule Tube Connections, Female to Female |

| Temperature Ratings | (232C)/Grafoil 700 F(371C), PTFE 450F |

| Pressure Rating | 150#, 300#, 600#, 800#, 1500# |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Ends | Flange Ends, Screwed Ends,Socket Weld Ends |

| Type | Ball Valves, Globe Valves, Check Valves, Needle Valves, Butterfly Valves |

| Temperature Rating | (232C)/Grafoil 700 F(371C),PTFE 450F |

Different Types

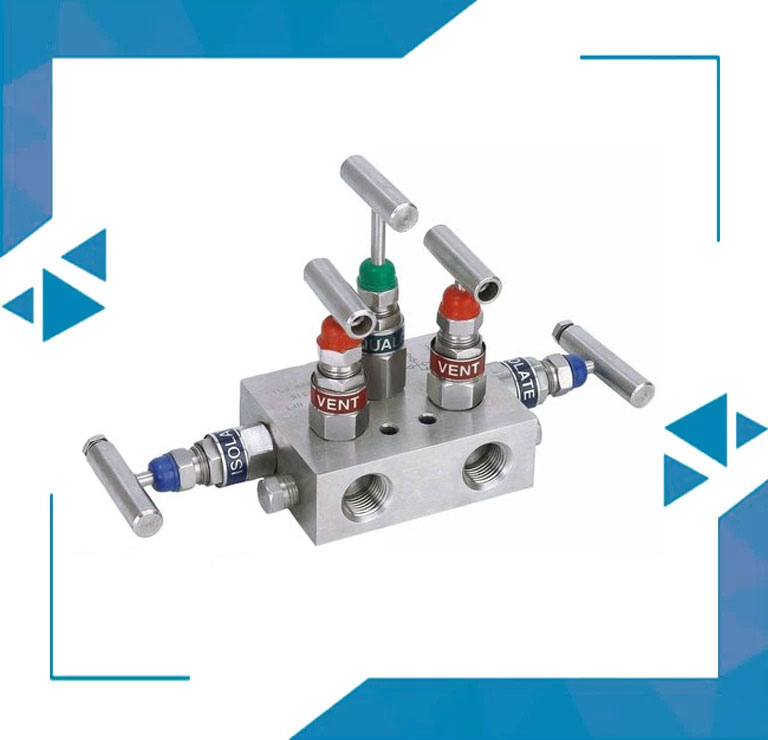

Nickel Alloy Manifold Valves

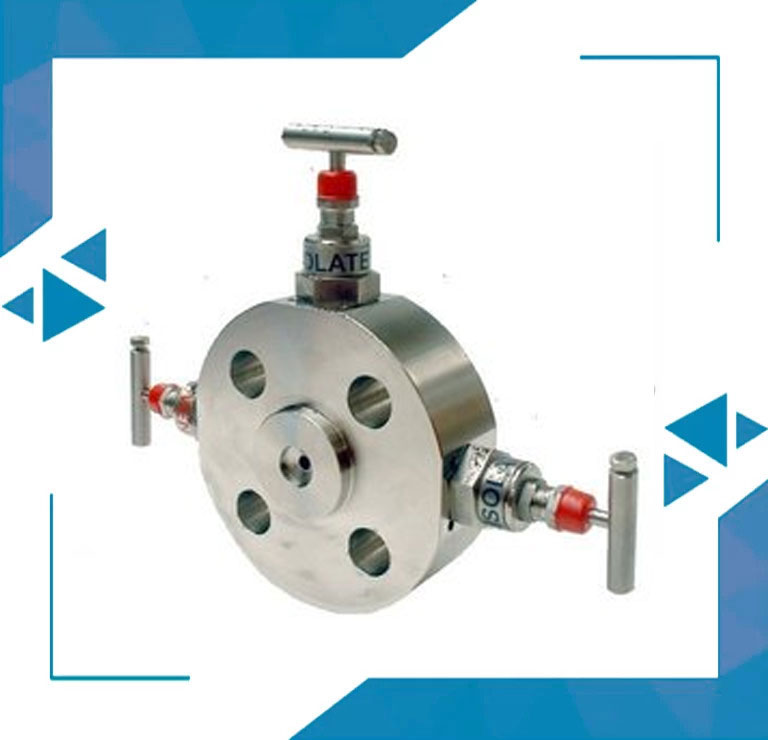

Nickel Alloy Monoflange Manifold Valves

Nickel Alloy Double Block & Bleed Valves

Nickel Alloy Needle Valves

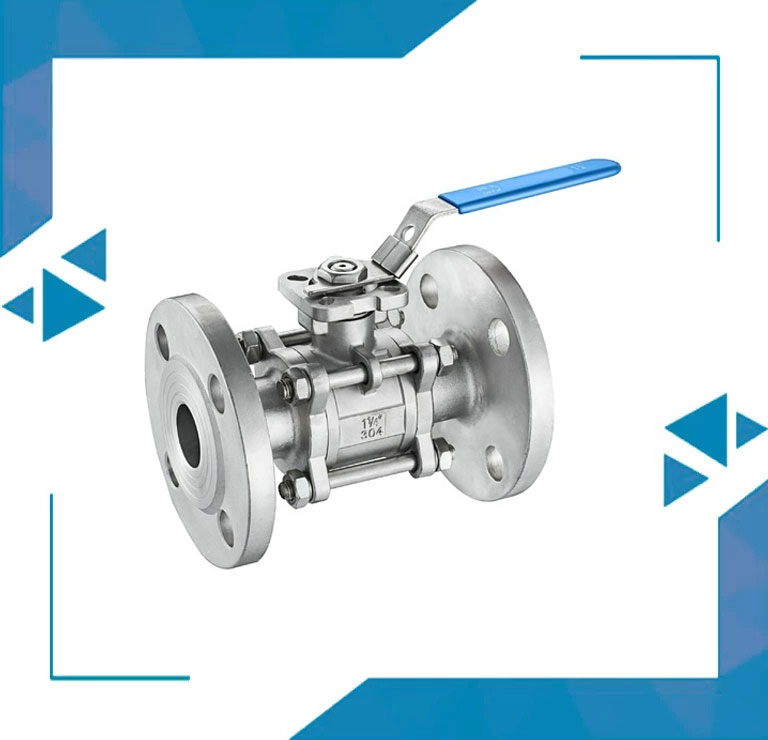

Nickel Alloy Ball Valves

Nickel Alloy Check Valves (nrv) & Piston

Contact us to get a quick quote for your requirement.

We offer These Nickel Alloy Valves as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Nickel High Pressure Ball Valves

- Nickel Alloy Panel Mounted Ball Valve

- Nickel Alloy 4 Way Ball Valve

- Nickel Alloy Ball Valve

- Nickel Instrumentation Check Valve

- Nickel Alloy Block Bleed Valve

- Ni Threaded Butterfly Valves

- Nickel Alloy Mini Needle Valve

- Nickel Alloy Instrumentation Needle Valve

- Nickel Alloy Panel Mounted Needle Valve

- Nickel Alloy Industrial Valves

- Ni Alloy Pannel Mounting Ball Valve

- Ni Monoflange Valves

- Nickel Alloy Forged Steel Valves

- Nickel Alloy Instrumentation Non Return Valve

- Nickel Manifold Check Valve

- Nickel Alloy Monoflange Manifold Valves

- Nickel Alloy Manifold Check Valve

- Nickel Bleed and Purge Valves

- Nickel Alloy NRV Check Valve

- Ni Hydraulic Ball Valve

- Nickel Alloy Instrumentation Ball Valves

- Nickel Alloy High Pressure Ball Valve

- Nickel Alloy High Pressure Needle Valve

- Nickel Alloy Ball Valve Threaded

- Nickel Alloy Female X Female Check Valve

- Nickel 3-way Flange Ball Valves

- Nickel Alloy 2 Way Ball Valves

- Nickel Alloy Forged-Body Needle Valves

- Nickel Alloy Pressure Reducing Valve

- Ni 3 PCS Ball Valve

- Nickel Alloy Forged Integral Bonnet Angle Type Needle Valves

Pressure Rating

| Temp. °F | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

|---|---|---|---|---|---|---|---|

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 [1] | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 [1] | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 [1] | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 [1] | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 [1] | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 [1] | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 [1] | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 [1] | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 [1] | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 [1] | 25 | 35 | 55 | 80 | 135 | 230 |

Dimension Standards

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Nickel Alloy Valves Across the Globe

Domestic Supply Nickel Alloy Valves

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004