Inconel 601 Instrumentation Accessories Manufacturer

Home / Inconel Instrumentation Accessories / Inconel 601 Instrumentation Accessories

Global Steel is a company that specializes in the creation and production of industrial products like Inconel 601 Instrumentation Accessories and other items.

Table Of content

- About Inconel 601 Instrumentation Accessories

- Specification List of Inconel 601 Instrumentation Accessories

- Equivalent Grades Of Inconel 601 Instrumentation Accessories

- Different Types of Inconel 601 Instrumentation Accessories

- Available Stock of Inconel 601 Instrumentation Accessories

- Chemical Structure of Inconel 601 Instrumentation Accessories

- Mechanical Properties of Inconel 601 Instrumentation Accessories

- We Serve Application Industry

- We Export Inconel 601 Instrumentation Accessories Across the Globe

- Domestic Supply Inconel 601 Instrumentation Accessories

Inconel 601 Instrumentation Fittings are available in a wide range of products for a number of industrial applications. Because of the qualities of Incoloy 601, Instrumentation fittings constructed of Inconel alloy 601 are well recognized for their resistance to oxidation and erosion. Alloy 601’s perfect characteristics allowed its fittings to resist a wide range of temperature changes. Heat treatment plants, food processing industries, oil and gas sectors, as well as other industrial domains, employ Inconel 601 fittings. The inconel 601 fittings have a high strength, good workability, and are made of a nickel-chromium alloy with aluminium added to withstand oxidation at high temperatures. Because of their ability to join pipes composed of different materials, these fittings play an important role in the glass industry. These fittings are also ideally suited for use in the pulp and paper sector since they are sturdy, leak-free, and corrosion-free, and their good design allows for weldability throughout a wide temperature range. Its perfect properties allow it to be used in a variety of industrial applications. Pharmaceuticals, petrochemicals, pulp and paper, oil and gas, and other industries are among those that use instrumental valves. This is how industries maintain a steady flow of operations.

Our learning is dependent on cutting-edge technology and a team of highly skilled and experienced people. We use cutting-edge technologies in our production process to reach the highest level of precision. Three pillars support our organization: performance, value, and dependability. We think that consistent product performance leads to product stability, which adds value to our customers.

What is the hardness of Inconel 601 Instrumentation Accessories?

The hardness of Inconel 601 instrumentation accessories can vary depending on the specific form and manufacturing process. Typically, the alloy has a hardness of around 170-230 HB (Brinell hardness) or 15-20 HRC (Rockwell C hardness). The hardness can be affected by heat treatment, cold working, impurities, or other alloying elements. Inconel 601 is known for its high-temperature strength and excellent resistance to oxidation and corrosion, making it suitable for use in demanding industrial environments.

What industries commonly use Incoloy 601 instrumentation accessories?

Inconel 601 instrumentation accessories are commonly used in various high-temperature and corrosive environments, including the chemical processing, petrochemical, and power generation industries. They are also used in the aerospace and defense sectors, where high-temperature strength and excellent corrosion resistance are critical for many applications. Inconel 601 uses for a wide range of instrumentation accessories, such as thermowell, valves, and fittings, due to its excellent high-temperature properties and resistance to oxidation and corrosion.

What are the advantages of using Incoloy 825 instrumentation accessories?

Incoloy 825 instrumentation accessories offer several advantages. The alloy is highly resistant to corrosion, particularly in harsh environments, making it ideal for chemical processing and petrochemical plants. It is also highly resistant to oxidizing and reducing acids and can operate in high-temperature and high-pressure environments. Additionally, Incoloy 825 is easily weldable, has good mechanical strength, and is compatible with many other materials, making it a versatile choice for instrumentation applications.

Specification of Inconel 601 Instrumentation Accessories

| Syphon Size | 1/2 inch |

| Condensate Pot Size | Pipe size 2″, 3″, 4″, 6″ and larger size upon request. Standard length: Pipe length 8″, 10″, 12″, and larger length upon request. Pipe Schedule: 40, 80, 160, seamless pipe. NPT as per ANSI B2.1 taper pipe thread?” furnished. Socket weld as per ANSI B16.11 Butt weld as per ANSI B16.9 Working pressure: 6000 PSIG (41.34 MPa). |

| Snubber Size | Bore sizes 3/4″ to 10″ in diameter Travel ranges from 5″ to 20″ Load capacities from 738 lbs. to 187,900 lbs. |

| Pipe Clamps | 1/2 – 18 Inch |

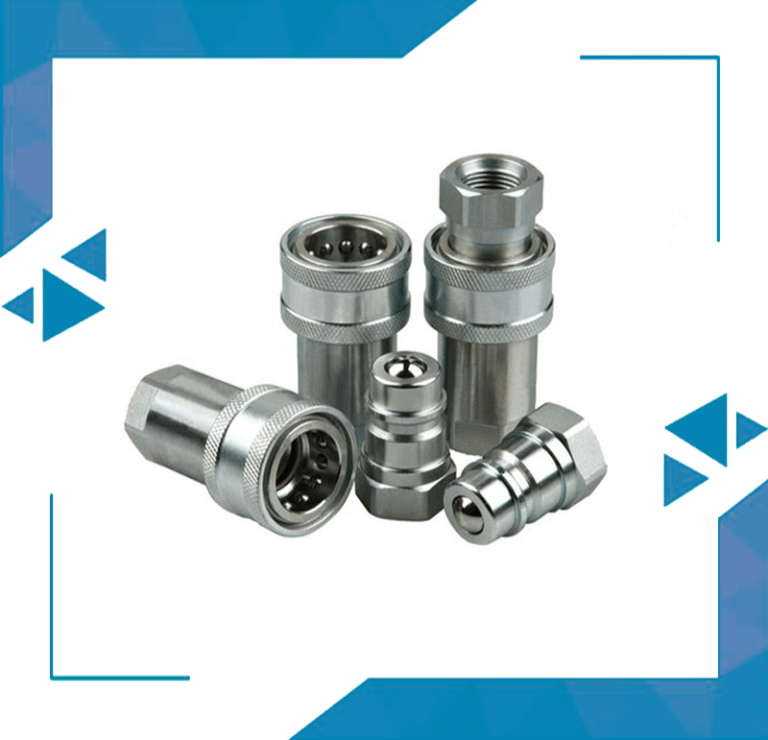

| Types | Condensate Pot, Air Header, Pipe Clamp, Quick Release Coupling, Syphon Tube / Pipe, Pipe Clamp, Snubber, Lock Nut For O-seal, Gauge Snubber, Thermocouple, Thermowell, Gauge Adaptors, Gauge Saver, Pressure Gauge Accessories, Mini Ball Valve, Over-Pressure Protector, Cooling Tower, Adjustable Snubber |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Air Header Size | Inlet Connection Size:1/2, 3/4, 1 inch Raised Face, Female NPT, BSPT, BSPP 2″,3″ & 4″. inches Drain Connection Type:Female NPT, BSPT, BSPP Drain Port Size:1/2″, 3/4″, 1″ Working Pressure:6000 psi [413 bar] |

| Test Certificates |

|

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

Different Types

Inconel 601 Condensate Pot

Inconel 601 Pipe Clamp

Inconel 601 Air Headers

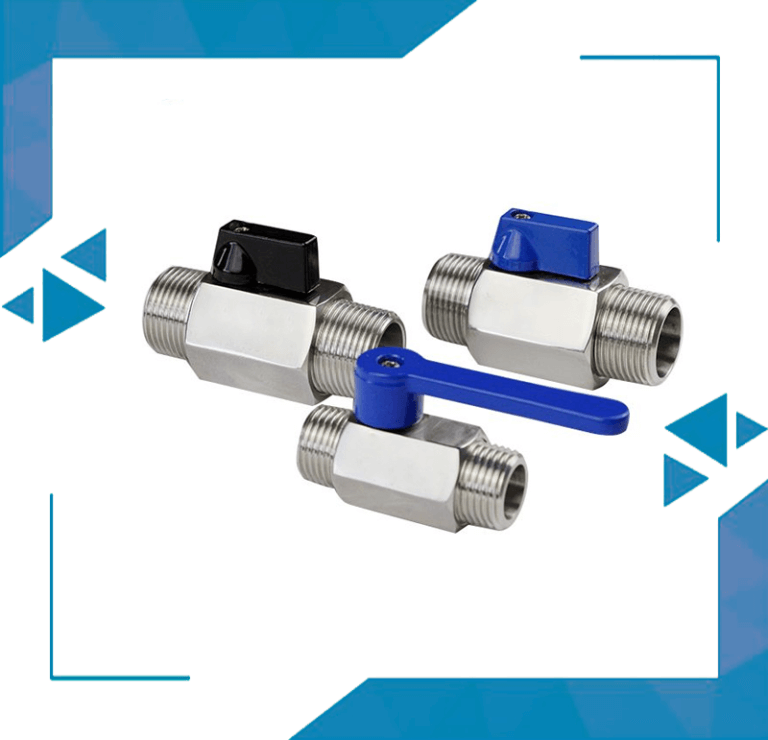

Inconel 601 Mini Ball Valve

Inconel 601 Snubber

Inconel 601 Quick Release Couplings

Contact us to get a quick quote for your requirement.

We offer These Inconel 601 nstrumentation Accessories as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Inconel Alloy 601 Adjustable Snubber

- Inconel Gr 601 Valves & Pump Components

- Alloy 601 Instrument Accessories

- Grade 601 Inconel Snubber

- Nickel Alloy 601 Thermowell

- Inconel 601 Gauge Union

- Inconel® Alloy 601 Inconel Thermowells

- Alloy 601 Test Plug

- UNS N06601 Inconel Mini Ball Valve

- Inconel 601 Gauge Snubber

- Inconel Alloy 601 Insert

- Inconel 601 Ferrule Pack

- Alloy 601 Over-Pressure Protector

- Type 601 Inconel Industrial Precision Turned Components

- Inconel 601 Orbital Weld Fittings

- 601 Inconel Front Ferrule

- 601 Inconel Flare End Fittings

- Inconel N06601 Precision Pipe Fittings

- Inconel 601 Flushing Ring

- 601 Inconel Syphon

- 601 Inconel Needle Valve

- 601 Inconel Lock Nut For O-seal

- Inconel 2.4851 Pressure Gauge Accessories

- Inconel 601 Positionable Lock Nut

- 601 Inconel Gauge Saver

- Alloy 601 Compression Fittings

- Inconel 601 STP Test Plug

- Inconel Alloy 601 SSN Snubber

- 601 Inconel NVA Needle Valve

- Inconel 2.4851 Thermowell

- Inconel 601 SOP Over Pressure Protector

- Inconel 601 Gauge Adaptors

- Inconel 601 BBV Double Block & Bleed Valve

- Inconel 601 Fir Isolation Ring Tees

- Inconel 601 SCT Cooling Tower

- Inconel® Alloy 601 Instrumentation Accessories

- 601 Inconel Back Ferrule

- Inconel® Alloy 601 SMV Mini Ball Valve

- Alloy 601 MVA 3 and 5 Handle Manifold Valves

- Alloy 2.4851 Gauge Union

- 601 Inconel Pressure Gauge Accessories

- 601 Inconel SNV Needle Valve

- Alloy 601 Thermocouple

- Inconel Alloy 601 Pressure Gauge Syphons

- 601 Inconel Ferrule & Single Ferrule Tube Fittings

- Alloy 601 Gauge Adaptors

- Alloy 601 SAS Adjustable Snubber

- Inconel Grade 601 Instrumentation Tubes

- NCF 601 Hose Fittings

Chemical Structure

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

We Serve Application Industry

Application Industry

Instrumentation Accessories applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Inconel 601 Instrumentation Accessories Across the Globe

Zimbabwe, Hungary, Taiwan, Argentina, Bhutan, Tibet, Hong Kong, Philippines, Bulgaria, Namibia, Brazil, Gambia, Denmark, China, Jordan, Ghana, India, Mexico, South Korea, Yemen, Venezuela, Russia, Gabon, Iran, Colombia, South Africa, Bangladesh, Greece, Chile, Czech Republic, Kazakhstan, Mongolia, Belarus, Nigeria, Puerto Rico, Ecuador, Poland, Angola, Spain, Qatar, Slovakia, Nepal, Japan, Ukraine, Libya, Ireland, Norway, Peru, Lebanon, United Arab Emirates, Vietnam, France, Lithuania, Serbia, Bahrain, Finland, Canada, Germany, Malaysia, Thailand, United States, United Kingdom, Bolivia, Saudi Arabia, Kenya, Austria, Egypt, Algiera, Belgium, Israel, Pakistan, Azerbaijan, Oman, New Zealand, Romania, Estonia, Singapore, Trinidad & Tobago, Afghanistan, Turkey, Netherlands, Sri Lanka, Portugal, Lahore, Indonesia, Switzerland, Morocco, Tunisia, Kuwait, Italy, Croatia, Algeria, Australia, Macau, Sweden, Iraq, Costa Rica, columbia.

Domestic Supply Inconel 601 Instrumentation Accessories

Haryana, Chandigarh, Ernakulam , Bhopal, Visakhapatnam, mumbai, Hyderabad, Indore, Jaipur, Secunderabad, Navi Mumbai, Noida, Nashik, Thiruvananthapuram, Surat, Ludhiana, Pimpri-Chinchwad, Gurgaon, Ranchi, Kolkata, Nagpur, Thane, Faridabad, Ahmedabad, Howrah, New Delhi, Pune, Jamshedpur, Rajkot, Bengaluru, Kanpur, Chennai.

Materials

- Stainless Steel Products

- Duplex / Super Duplex Steel Products

- Carbon Steel Products

- Alloy Steel Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Nickel Alloy Products

- Titanium Products

- Other Products

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004