Hastelloy C22 Pipe Fittings Manufacturer

Home / Hastelloy Pipe Fittings / Hastelloy C22 Pipe Fittings

We Global Steel are a reputed top Manufacturer, Supplier, and Stockist of Hastelloy C22 Pipe Fittings in different alloy grades. Supplying in the Domestic and Global Markets. Additionally, we are also known for being one of the leading exporters and importers of Hastelloy C22 pipe fittings in the competitive markets since many years. All our products are exported as per the needs and specifications of the customers.

The Hastelloy C22 Pipe Fittings are very wonderful as it exhibits excellent chemical and mechanical properties. These properties allow the fittings to stand strong even under elevated temperatures. There are many types of pipe fittings that are used to join two different or similar kinds of fittings or pipes so that fluids in those pipes can be directed in different directions.

Table Of content

- About Hastelloy C22 Pipe Fittings

- Specification List of Alloy C22 Pipe Fittings

- Equivalent Grades Of Hastelloy C22 Pipe Fittings

- Manufacturing Standards of ASTM B366 C22 Pipe Fittings

- Different Types of Hastelloy C22 Pipe Fittings

- Available Stock of Alloy C22 Buttweld Pipe Fittings

- Hastelloy C22 Pipe Fittings Dimensional Tolerances

- Chemical Structure of Hastelloy C22 Pipe Fittings

- Mechanical Properties of Alloy C22 Pipe Fittings

- We Serve Application Industry

- We Export Hastelloy C22 Pipe Fittings Across the Globe

- Domestic Supply Hastelloy C22 Pipe Fittings

There are many applications where Hastelloy C22 Pipe Fittings are widely used, including petrochemical, offshore and oil and gas industries, pulp and paper, condensers, chemical types of equipment, nuclear plants, gas processing, pharmaceutical, heat exchangers, specialty chemicals, and more. But above all, the alloys of our C22 Fittings are the most demanded fittings in seawater and areas having brine water as it offers great strength and resistance when used in any pipe systems or application industries.

These Pipe fittings offer features such as higher mechanical and tensile strength, the yield strength is also high. These fittings are easy to weld and can be easily fabricated, and also they offer good formability.

It also has the features such as corrosion, pitting and crevices, oxidation, stress, corrosion cracking resistance, corrosion resistance against nitric acid, and sulfuric acid. We conduct several Destructive, Non Destructive tests, some of them are hardness, micro, and macro testing, PMI tests, etc. Once the testing is done they are then sent for packing, we pack them in customize as well as standard packaging.

Is Hastelloy C22 hard to weld?

Common fusion welding can be performed with any current welding power supply with sufficient output and controls. Generally, weld heat input is controlled in the low to moderate range. Nickel-based alloys generally exhibit sluggish welding and shallow penetration characteristics; therefore, the possibility of incomplete fusion increases. You must use care to ensure a sound weld. Programs should utilise a pulsed current if orbital or automatic welding equipment is used. Pulsed current inputs can help control weld penetration without exclusive heat input. Pulsing also helps control the weld pool, improving the uniformity of the weld bead appearance.

Is Hastelloy c22 corrosion-resistant?

Hastelloy C22 pipe is popular corrosion resistant in harsh environments where other alloys fail. This alloy is considered a ‘superalloy’ due to its extreme corrosion resistance. The material is commonly used in reactor vessels, piping, flanges, fittings, pumps, and valves in the pharmaceutical industry. The alloy comprises nickel, molybdenum, and chromium with a small amount of tungsten. Nickel typically composes more than 50% of the alloy, but every manufacturer has a slight variation in the amount of material in their composition.

What are the mechanical properties of Hastelloy C22 pipe Fitting?

Hastelloy C22 pipe is a nickel-chromium-molybdenum solid solution strengthened super-alloy with a nominal chemical composition of 56% nickel, 22% chromium, and 13% molybdenum, with additions of iron, tungsten, and cobalt. It is commonly referred to by the tradename Hastelloy® C22 and the universal designation UNS N06022. It resists almost all reducing and oxidizing environments, including strong oxidizers, seawater, and organic acids. In addition, C22 has excellent resistance to chloride-induced localized corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

Specification of Alloy C22 Pipe Fittings

| Standards | ASTM AB366 / ASME SB366 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size |

|

| Type | Seamless / Welded / Fabricated |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | – | NiCr21Mo14W | – |

Manufacturing Standards

| ASME B16.9 ASTM B366 C22 Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Different Types

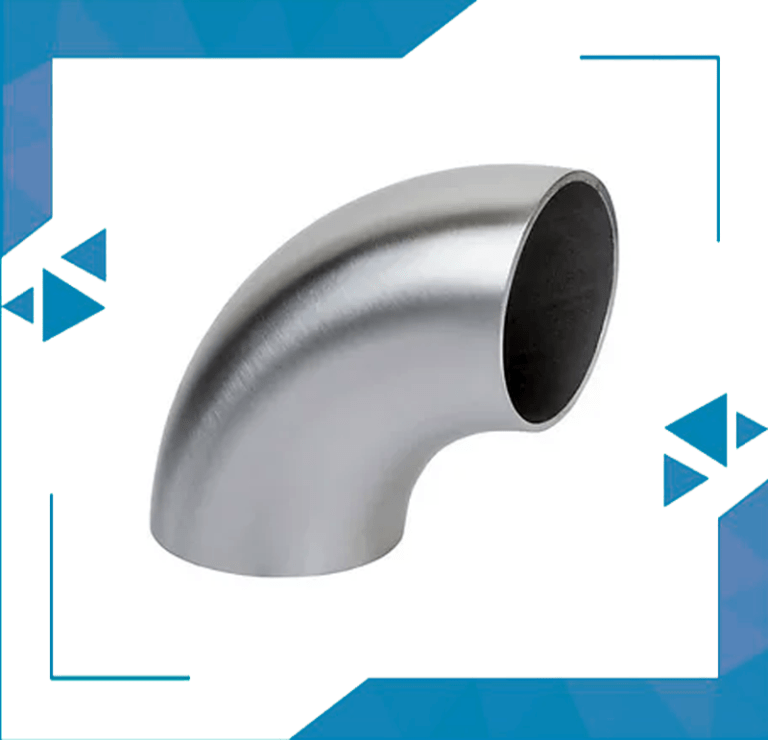

Hastelloy C22 Pipe Elbow

Hastelloy C22 Pipe Tee

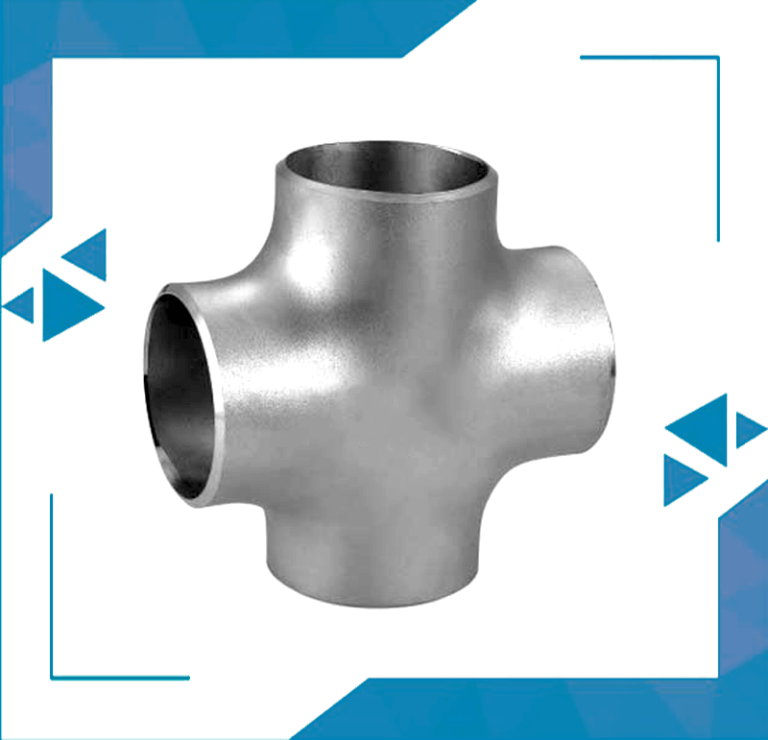

Hastelloy C22 Pipe Cross

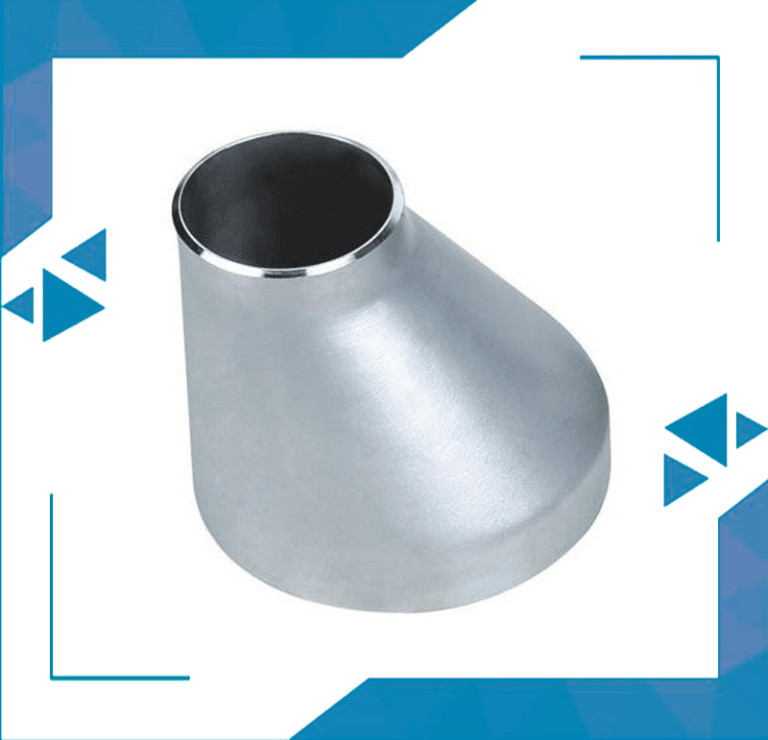

Hastelloy C22 Reducers

Hastelloy C22 Pipe Cap

Hastelloy C22 Stub End

Contact us to get a quick quote for your requirement.

We offer These Hastelloy C22 Buttweld Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Alloy C22 Reducers

- ASTM B366 C22 Hastelloy Lateral Tee

- Type C22 Hastelloy Industrial Buttweld Fittings

- UNS N06022 Buttweld Fittings

- Hastelloy® Alloy C22 Pipe Reducing Tee

- UNS N06022 Hastelloy 2D Elbow

- ANSI B16.9 Hastelloy C22 Pipe Caps

- ASME B16.28 Hastelloy Alloy C22 Two Joint Pipe Fittings

- Grade C22 Hastelloy Pipe Fittings

- Hastelloy Alloy C22 Buttweld Pipe Fittings

- C22 Hastelloy Two Halve Butt weld Fittings

- C22 Hastelloy 1D Elbow

- Hastelloy Alloy C22 Lap Joint Stub Ends

- Hastelloy C22 45° Short Radius Elbow

- Hastelloy C22 45 Degree Pipe Elbow

- Hastelloy C22 Pipe Bends

- Alloy 2.4602 Two Joint Pipe Fittings

- Hastelloy Alloy C-22 180° Buttweld Elbow

- Alloy C22 Butt Weld Elbows 90°-SR- ASME B16.9

- Hastelloy Alloy C22 Buttweld Pipe Fittings

- Hastelloy C22 Buttweld Elbow

- Hastelloy C22 Eccentric Reducer

- Hastelloy C22 Pipe Bends

- Hastelloy C22 Concentric Reducer

- Hastelloy C22 Reducing Elbow

- Hastelloy C22 Buttweld Pipe Nipple

- C22 Hastelloy Stub End

- ANSI B16.28 C22 Hastelloy Seamless Pipe Fittings

Dimensional Tolerances

| 1/2 TO 2-1/2 | +1/16 | ±1/32 | Not less than 87-1/2% of Normal Thickness | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 12 to 4 | 1/32 | 1/16 |

| -1/32 | 5 to 8 | 1/16 | 1/8 | |||||||||

| 3 TO 3-1/2 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 10 to 12 | 3/32 | 3/16 | |

| 4 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 14 to 16 | 3/32 | 1/4 | |

| 5 TO 8 | +1/32 | ±1/16 | ±1/16 | ±1/16 | ±1/4 | ±1/4 | ±1/4 | ±1/32 | 18 to 24 | 1/8 | 3/8 | |

| -1/16 | ||||||||||||

| 10 TO 18 | +1/16 | ±1/8 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | All dimensions are in inches | |||

| -1/8 | ||||||||||||

| 20 TO 24 | +1/4 | ±3/32 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | ||||

| -3/32 | ||||||||||||

Chemical Structure

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Hastelloy C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Hastelloy C22 Pipe Fittings Across the Globe

New Zealand, Saudi Arabia, Turkey, Bolivia, Ireland, United Kingdom, Nigeria, Romania, Macau, Belgium, Argentina, Colombia, Brazil, Nepal, Vietnam, Poland, Spain, Estonia, Chile, Australia, Sweden, Philippines, South Africa, Namibia, Germany, Gabon, Netherlands, Israel, Malaysia, Denmark, Finland, Mongolia, Kenya, Bulgaria, Qatar, Trinidad & Tobago, India, Russia, Sri Lanka, Lebanon, South Korea, Azerbaijan, Tibet, Oman, Canada, Puerto Rico, Peru, Bahrain, Tunisia, Ukraine, Slovakia, Norway, Hungary, Switzerland, Kuwait, Lithuania, Lahore, Egypt, Algeria, Czech Republic, Greece, Portugal, Algiera, Kazakhstan, Angola, Italy, Bhutan, Ghana, Afghanistan, Serbia, Yemen, France, Croatia, Indonesia, United Arab Emirates, Iran, Hong Kong, China, Austria, United States, Thailand, Mexico, Pakistan, Belarus, Bangladesh, Taiwan, Costa Rica, Ecuador, Zimbabwe, Gambia, Venezuela, Japan, Singapore, Libya, Morocco, columbia, Jordan, Iraq.

Domestic Supply Hastelloy C22 Pipe Fittings

New Delhi, Jaipur, Pimpri-Chinchwad, Gurgaon, Chennai, Ludhiana, Howrah, Ernakulam , Indore, Haryana, Navi Mumbai, Faridabad, Hyderabad, Kanpur, Rajkot, Bhopal, Thiruvananthapuram, Ahmedabad, Kolkata, Visakhapatnam, Ranchi, Chandigarh, Jamshedpur, Bengaluru, Thane, Surat, Noida, Secunderabad, Pune, Nagpur, Nashik, mumbai.

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004