Alloy Steel Flanges Manufacturer

Home / Alloy Steel Flanges

Global Steel is a reputed Alloy Steel Flange manufacturer, Supplier, and Stockist. These Alloys Steel flanges are available in several grades which include, F1, F5, F9, F11, F22, F91, etc., all of these grades are has a certain amount of chemical composition.

Table Of content

- About Alloy Steel Flanges

- Specification List of Alloy Steel Flanges

- Manufacturing Standards of Alloy Steel Flanges

- Different Types of Alloy Steel Flanges

- Available Stock of Alloy Steel Flanges

- Alloy Steel Flanges Weight Chart

- Alloy Steel Pipe Flange Dimensions

- Alloy Steel Flanges Pressure Rating

- Chemical Structure of Alloy Steel Flanges

- Mechanical Properties of Alloy Steel Flanges

- We Serve Application Industry

- We Export Alloy Steel Flanges Across the Globe

- Domestic Supply Alloy Steel Flange

These Alloy Steel Pipe Flanges have a variety of amazing qualities to provide, like Abrasive coating, Tamper proof, Protected, Adequate raw material, Efficient, Perfect finish, Longer life, Accurate dimension, and others. We also provide these products in customized sizes and forms to our clients. Flanges are forged or cast rings that are used to connect parts of a pipe or any type of machine requiring an intermediate connecting point. Aside from carbon, this alloy steel includes significant amounts of Nickel, Manganese, Chromium, Silicon, Tungsten, Vanadium, and Molybdenum. Furthermore, they are fortified with trace amounts of elements like sulphur, silicon, manganese, and phosphorous, which aid in boosting hardness, strength, chemical resistance, and other properties.

The Solution annealing on these flanges is not necessary because the mechanical properties are shown in the built state. These Alloy Steel Flanges are made from chromium, and they are used to resist scaling at temperatures greater than 1100 degrees.

These flanges can withstand wind exposure, pollution from industrial processes, and elevated temperatures, which are closer to the sea, which is the leading cause of saltwater pollution. Alloy Steel Flanges have the highest chromium content, which makes them beneficial to wet corrosion resistance. These flanges also resist scaling at high temperatures.

Once these flanges have been fabricated, they are forwarded for testing, where numerous destructive tests are performed to ensure that they are free of damage and of the highest quality. We value the packing among these products since providing a flawless product is vital to us.

What types of Alloy Steel Flanges are Available?

Various types of alloy steel flanges are available to suit different piping requirements. Common types include weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, threaded flanges, and lap joint flanges. These flanges come in different sizes, pressure ratings, and facing options, allowing for flexible installation and assembly of piping systems.

Can Alloy Steel Flanges be used in low-temperature applications?

Yes, alloy steel flanges can be used in low-temperature applications, depending on the specific grade of alloy steel used. Some alloy steels are designed to maintain strength & toughness even at low temperatures. It is important to select the appropriate alloy steel grade for sub-zero temperature applications, such as ASTM A350 LF2.

What are the temperature limitations of Alloy Steel Flanges?

The temperature limitations of alloy steel flanges depend on the specific grade of alloy steel used. Some alloy steels can withstand high temperatures up to 1000°C (1832°F) or even higher making them suitable for power generation & petrochemicals applications.

Specification of Alloy Steel Flanges

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Manufacturing Standards

| ASME/ANSI B16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B16.36 | Orifice Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Different Types

Alloy Steel Slip On Flanges

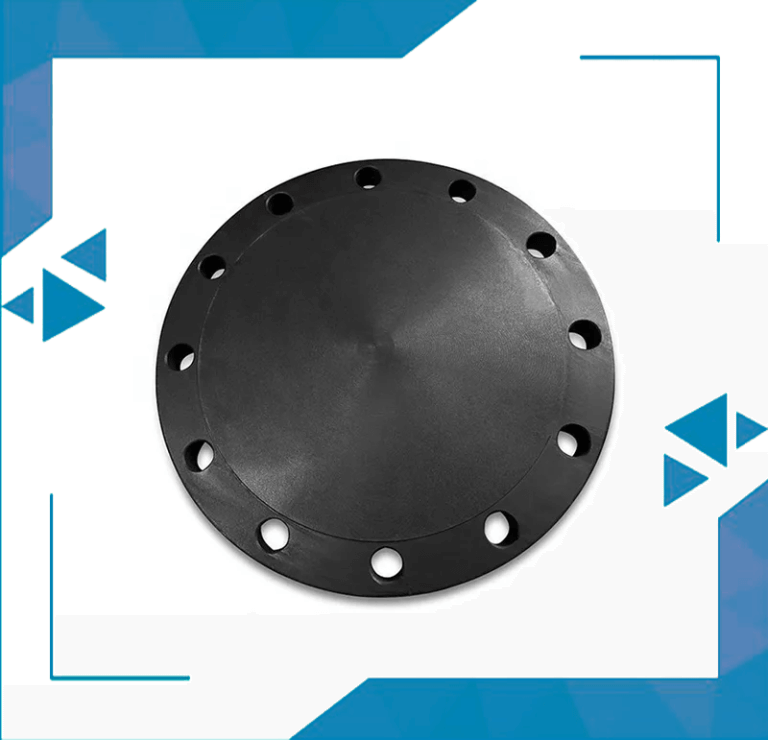

Alloy Steel Blind Flanges

Alloy Steel Socket Weld Flanges

Alloy Steel Weld Neck Flanges

Alloy Steel Reducing Flanges

Alloy Steel Orifice Flanges

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel Flanges as per DIN, ASTM, ASME, BS, EN, JIS or ANSI Standard.

Available Stock

- ASME B16.47 Crmo Spades Ring Spacers Flanges

- Alloy Steel Lap Joint Flanges

- Alloy Steel Plate Flange

- Type ASME SA182 Alloy Steel Industrial Forged Flanges

- Alloy Steel Male & Female Flanges

- Alloy Steel Nipoflange

- Chrome Molybdenum Steel Pipe Flange

- Chromium Molybdenum Tongue Flanges

- CrMo Flanges

- Cr-Mo Expander Flanges

- Alloy Steel Lapped Joint Flanges

- Alloy Steel BS Standard Table E

- ASME SA182 Alloy Steel 150 LBS Threaded Flanges

- Alloy Steel British Standard Table D Pipe Flanges

- Chrome Molybdenum Long Welding Neck Flange

- Chrome Moly Spectacle Blind Flanges

- Alloy Steel Flanges

- Alloy Steel 1500 LBS Flanges

- Cr-Mo Nipo Flanges

- Cr-Mo Spades Ring Spacers Flanges

- Alloy Steel PN 10 Flange

Weight Chart

15mm (1/2″) Alloy Steel Flanges Weight Chart

Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Chemical Structure

| Grade | C | Mn | P | S | Si | Mo | Cb |

| F1 | 0.28 | 0.60 – 0.90 | 0.045 | 0.045 | 0.15 – 0.30 | 0.44-0.65 | – |

Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| F1 | 485 | 275 | 20 | – | 143-192 |

We Serve Application Industry

Application Industry

ANSI / ASME 16.5, 16.48, 16.47 Flanges applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Alloy Steel Flanges Across the Globe

Greece, India, New Zealand, Venezuela, Turkey, Indonesia, Ecuador, Kazakhstan, Belarus, Libya, Thailand, United Arab Emirates, Mexico, Oman, columbia, Malaysia, Ireland, Lithuania, China, Bhutan, Bangladesh, Ghana, Argentina, Qatar, Trinidad & Tobago, Gambia, Netherlands, United States, Australia, Tibet, Gabon, Lahore, Israel, Egypt, Estonia, Finland, Iran, Nigeria, Morocco, Italy, Poland, Lebanon, Taiwan, Romania, Mongolia, France, Nepal, Azerbaijan, South Korea, Spain, South Africa, Saudi Arabia, Serbia, Afghanistan, Croatia, Czech Republic, Slovakia, Iraq, Bahrain, Austria, Peru, Colombia, Zimbabwe, Japan, Namibia, Canada, Vietnam, Kenya, Puerto Rico, Sweden, Bulgaria, Bolivia, Singapore, Switzerland, United Kingdom, Norway, Hong Kong, Jordan, Brazil, Philippines, Costa Rica, Denmark, Yemen, Germany, Pakistan, Portugal, Algeria, Sri Lanka, Kuwait, Ukraine, Russia, Tunisia, Algiera, Hungary, Angola, Macau, Chile, Belgium.

Domestic Supply Alloy Steel Flanges

Jamshedpur, Indore, Ranchi, Faridabad, New Delhi, Ernakulam , Surat, Hyderabad, Ahmedabad, Bhopal, Chennai, Visakhapatnam, Jaipur, Nagpur, Nashik, Pimpri-Chinchwad, Kanpur, Kolkata, Bengaluru, Thiruvananthapuram, Chandigarh, Haryana, mumbai, Rajkot, Howrah, Pune, Navi Mumbai, Thane, Gurgaon, Ludhiana, Noida, Secunderabad.

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004