Alloy Steel A182 F11 Flanges Manufacturer

Home / Alloy Steel Flanges / Alloy Steel A182 F11 Flanges

Alloy Steel A182 F11 Flanges are widely used in various industries such as oil and gas, chemical, and petrochemical. These flanges are made of a high-grade steel alloy containing chromium & molybdenum as their primary alloys & making them highly resistant to corrosion and wear.

Alloy Steel A182 F11 Flanges are a type of flange that belongs to the ASTM A182 standard. They are made from chromium-molybdenum alloy steel, which is why they are often called chrome-moly flanges. The primary alloys in these flanges provide superior strength, toughness & excellent resistance to corrosion and high-temperature environments.

Table Of content

- About ASTM A182 Alloy Steel F11 Flanges

- Specification List of ASTM A182 Alloy Steel F11 Flanges

- Equivalent Grades Of ASTM A182 Alloy Steel F11 Flanges

- Manufacturing Standards of ASTM A182 Alloy Steel F11 Flanges

- Different Types of ASTM A182 Alloy Steel F11 Flanges

- Available Stock of ASTM A182 Alloy Steel F11 Flanges

- ASTM A182 Alloy Steel F11 Flanges Weight Chart

- ASTM A182 Alloy Steel F11 Pipe Flange Dimensions

- ASTM A182 Alloy Steel F11 Flanges Pressure Rating

- Chemical Structure of ASTM A182 Alloy Steel F11 Flanges

- Mechanical Properties of ASTM A182 Alloy Steel F11 Flanges

- We Serve Application Industry

- We Export ASTM A182 Alloy Steel F11 Flanges Across the Globe

- Domestic Supply ASTM A182 Alloy Steel F11 Flanges

One of the primary benefits of A182 F11 Flanges is their high corrosion resistance. They can withstand corrosive environments & making them an excellent choice for chemical processing plants and oil and gas refineries. ASTM A182 F11 Flanges are also resistant to wear & tear, which makes them ideal for use in high-stress applications that require durability and strength.

ASTM A182 Alloy Steel F11 Flanges are used in various applications, such as pipeline systems, pressure vessels, and boilers. They are also used in heavy machinery and equipment, especially in industries that require high-temperature & pressure environments. These flanges are also used in chemical processing plants, oil and gas refineries & power generation plants. The high-quality flanges products we provide at Global Steel include Alloy Steel A182 F22 Flanges, Alloy Steel A182 F91 Flanges and more.

Alloy Steel F11 Forged Flanges have excellent high-temperature strength and toughness, making them ideal for use in high-pressure & high-temperature environments. They also have high oxidation resistance & are resistant to thermal fatigue. These properties make alloy steel Alloy Steel F11 Flanges a popular choice in the oil and gas industry, where they need to withstand high-temperature & corrosive environments. We provide an extensive range of products, such as SMO 254 Flanges, Ball Valves and more.

UNS K11597 Flanges are valuable in various industries due to their high strength, durability, and corrosion resistance. Alloy Steel 1.7335 Flanges are an excellent choice for applications that require high-temperature and pressure environments. Their properties make them ideal for chemical processing plants, oil and gas refineries & power generation plants. Alloy steel A182 F11 flanges are a perfect solution for engineers who demand high-quality and reliable flanges for their projects.

What are the key characteristics of Alloy Steel A182 F11 Flanges?

Alloy Steel A182 F11 Flanges exhibit good resistance to oxidation, corrosion & high-temperature creep. They have high tensile strength, yield strength, and hardness, allowing them to withstand demanding operating conditions. Additionally, they offer good weldability and machinability, facilitating their installation and maintenance.

In which applications are Alloy Steel A182 F11 Flanges commonly used?

Alloy Steel A182 F11 Flanges are commonly used in pipeline systems, refineries, petrochemical plants, power plants, and thermal process equipment. They are suitable for high-temperature & high-pressure environments where resistance to stress, corrosion and elevated temperatures is required.

What are the available sizes for Alloy Steel A182 F11 Flanges?

Alloy Steel A182 F11 Flanges are available in various sizes and pressure ratings to accommodate different piping systems. The sizes typically range from 1/2 inch to 48 inches, and the pressure ratings can vary from 150 pounds per square inch (psi) up to 2500 psi or even higher based on custom requirements.

Specification of Alloy Steel A182 F11 Flanges

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy Steel F11 | K11597/K11572 | 1.7335 |

Manufacturing Standards

| ASME/ANSI B16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B16.36 | Orifice Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Different Types

Alloy Steel A182 F11 Slip On Flanges

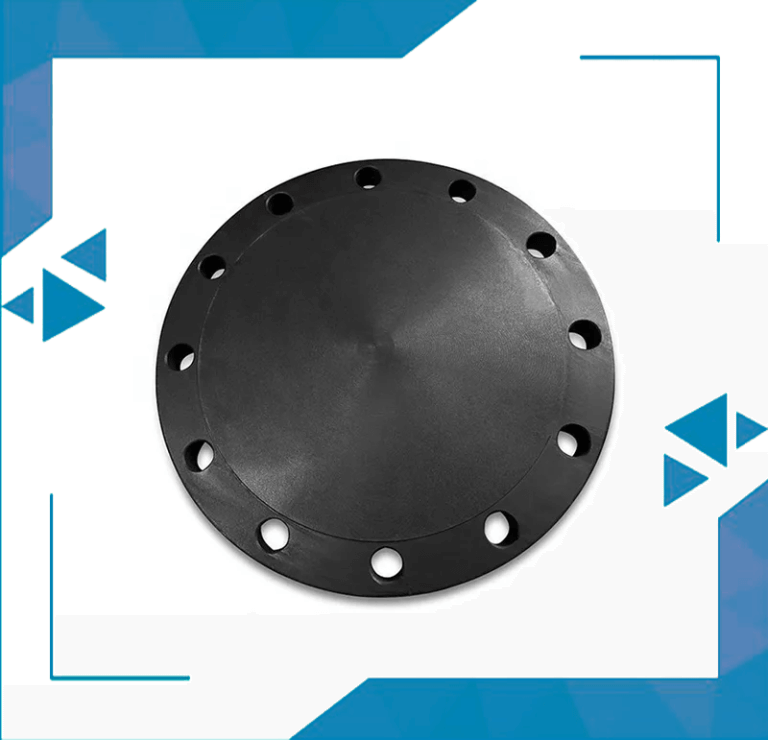

Alloy Steel A182 F11 Blind Flanges

Alloy Steel A182 F11 Socket Weld Flanges

Alloy Steel A182 F11 Weld Neck Flanges

Alloy Steel A182 F11 Reducing Flanges

Alloy Steel A182 F11 Orifice Flanges

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel A182 F11 Flanges as per DIN, ASTM, ASME, BS, EN, JIS or ANSI Standard.

Available Stock

- ASME B16.47 Crmo Spades Ring Spacers Flanges

- ASTM A182 Alloy Steel F11 PN 10 Flange

- ASME SA182 Alloy Steel F11 Nipoflange

- SA182 F11 Alloy Steel Flanges

- Chrome Molybdenum Steel F11 Pipe Flange

- ANSI B16.5 Cr-Mo Expander Flanges

- ASME SA182 F11 Alloy Steel Flanges

- Alloy Steel K11572 Male & Female Flanges

- UNS K11597 Lap Joint Flanges

- Chromium Molybdenum ASTM A182 F11 Tongue Flanges

- Type ASME SA182 Alloy Steel F11 Industrial Forged Flanges

- ASTM A182 Alloy Steel F11 Lapped Joint Flanges

- Cr-Mo A182 F11 Spades Ring Spacers Flanges

- Alloy Steel A182 F11 British Standard Table D Pipe Flanges

- ASTM A182 Cr-Mo F11 Nipo Flanges

- Chrome Moly A182 F11 Spectacle Blind Flanges

- Chrome Molybdenum ASME SA182 Long Welding Neck Flange

- Alloy Steel A182 F11 BS Standard Table E

- Alloy Steel 1.7335 1500 LBS Flanges

- ASME SA182 F11 Flanges

- CrMo A182 F11 Flanges

Weight Chart

15mm (1/2″) Alloy Steel A182 F11 Flanges Weight Chart

Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Chemical Structure

| Grade | C | Mn | P | S | Si | Ni | Ch | Mo | Cb |

| F11 | 0.15 | 0.30-0.60 | 0.030 | 0.030 | 0.50-1.00 | – | 1.00-1.50 | 0.44-0.65 | – |

Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| F11 | 415 | 205 | 20 | – | 121-174 |

We Serve Application Industry

Application Industry

ANSI / ASME 16.5, 16.48, 16.47 Flanges applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004