Alloy Steel A182 F91 Flanges Manufacturer

Home / Alloy Steel Flanges / Alloy Steel A182 F91 Flanges

Global Steel is a well-known, Manufacturer, Supplier, and Stockist of Alloy Steel A182 F91 Flanges. Our manufacturing units have well-defined and have advanced and upgraded machinery and equipment.

As a supplier of premium quality Alloy Steel A182 F91 Flanges, we offer a range of premium alloy steel products. Our alloy steel products contain Chromium-Nickel-Molybdenum properties that provide corrosion resistance and serviceability at elevated temperatures. Alloy Steel A182 F91 Flanges’ chemical composition has carbon, silicon, chromium, sulfur, manganese, phosphorus, and molybdenum that increase the machinability and usability of the alloy steel.

Table Of content

- About ASTM A182 Alloy Steel F91 Flanges

- Specification List of ASTM A182 Alloy Steel F91 Flanges

- Equivalent Grades Of ASTM A182 Alloy Steel F91 Flanges

- Manufacturing Standards of ASTM A182 Alloy Steel F91 Flanges

- Different Types of ASTM A182 Alloy Steel F91 Flanges

- Available Stock of ASTM A182 Alloy Steel F91 Flanges

- ASTM A182 Alloy Steel F91 Flanges Weight Chart

- ASTM A182 Alloy Steel F91 Pipe Flange Dimensions

- ASTM A182 Alloy Steel F91 Flanges Pressure Rating

- Chemical Structure of ASTM A182 Alloy Steel F91 Flanges

- Mechanical Properties of ASTM A182 Alloy Steel F91 Flanges

- We Serve Application Industry

- We Export ASTM A182 Alloy Steel F91 Flanges Across the Globe

- Domestic Supply ASTM A182 Alloy Steel F91 Flanges

We are widely known for providing different grades and specifications of Alloy Steel A182 F91 Flanges, which are suitable for machining, welding, grinding, or polishing, where good corrosion resistance is also needed. Alloy Steel A182 F91 Flanges are known for durability and easy maintenance; they are available in different specifications as per the specifications of clients. Our Alloy Steel A182 F91 Flanges are used in the Ship Building Industry, and so on.

The Alloy Steel A182 F91 Flanges equivalent flange has a low corrosion rate in flowing seawater, which makes it more suitable for marine applications owing to its Alloy Steel A182 F91 Flanges equivalent dimensional characteristics. Moreover, these Flange is available in a wide variety of sizes, thicknesses, and diameters, which meet the application requirements of our customers perfectly.

Our alloy steel products also meet chemical and mechanical requirements before being delivered to customers.

There are many industrial sectors where our flanges are applicable such as marine and chemical processing. We also understand the importance of packaging, and hence, we ensure that our Alloy Steel A182 F91 Flanges are delivered to you in the best condition without causing any damage to it, we respect our customer’s time constraints, and we, therefore, provide our quality Alloy Steel A182 F91 Flanges within the stipulated timeframe.

Is Alloy Steel A182 F91 Flange magnetic?

Alloy Steel A182 F91 is a high-strength alloy that contains chromium and molybdenum, which provide excellent corrosion resistance and high-temperature strength. The magnetic properties of Alloy Steel A182 F91 depend on the specific composition and manufacturing process used. In general, it is not a strongly magnetic material, but it may exhibit some magnetic properties due to iron and other magnetic elements in its composition.

What are the dimensions of Alloy Steel A182 F91 Flange?

Alloy Steel A182 F91 Flanges are available in various dimensions and specifications to meet various application requirements. The flanges are typically available in sizes ranging from ½ inch to 36 inches in diameter, with pressure ratings ranging from 150 to 2500 pounds. The exact dimensions of the flange depend on the specific standard or specification used, such as ASME B16.5 or ASTM A182, and on the type of flange, such as slip-on, weld neck, or socket weld.

What is the temperature range for Alloy Steel A182 F91 Flange?

Alloy Steel A182 F91 is a high-strength alloy designed explicitly for high-temperature service applications. The temperature range for Alloy Steel A182 F91 flanges depends on the specific application and environmental conditions. In general, the alloy can maintain its high-temperature strength and corrosion resistance up to 600-650°C (1112-1202°F), making it suitable for use in high-temperature steam and gas environments, as well as in other harsh chemical and petrochemical processing applications.

Specification of Alloy Steel A182 F91 Flanges

| Standards | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy Steel F91 | K90901 | 1.4903 |

Manufacturing Standards

| ASME/ANSI B16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B16.36 | Orifice Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Different Types

Alloy Steel A182 F91 Slip On Flanges

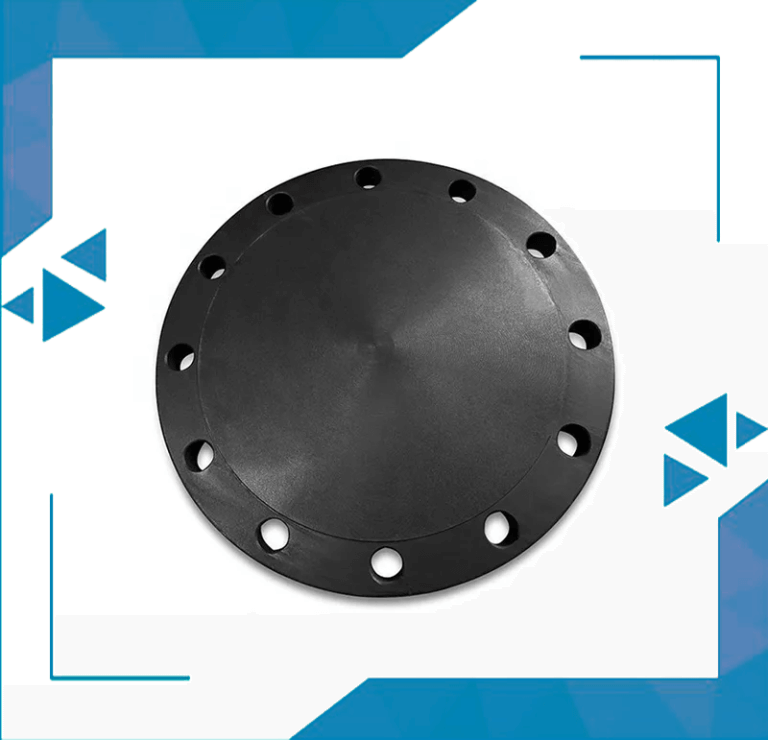

Alloy Steel A182 F91 Blind Flanges

Alloy Steel A182 F91 Socket Weld Flanges

Alloy Steel A182 F91 Weld Neck Flanges

Alloy Steel A182 F91 Reducing Flanges

Alloy Steel A182 F91 Orifice Flanges

Contact us to get a quick quote for your requirement.

We offer These Alloy Steel A182 F91 Flanges as per DIN, ASTM, ASME, BS, EN, JIS or ANSI Standard.

Available Stock

- ASME SA182 Alloy Steel F91 Nipoflange

- Chrome Molybdenum Steel F91 Pipe Flange

- Alloy Steel ASTM A182 F91 Plate Flange

- Chromium Molybdenum ASTM A182 F91 Tongue Flanges

- ASME B16.47 Crmo Spades Ring Spacers Flanges

- ASME SA182 F91 Alloy Steel Flanges

- UNS K90901 Lap Joint Flanges

- CrMo A182 F91 Flanges

- Alloy Steel K90901 Male & Female Flanges

- ANSI B16.5 Cr-Mo Expander Flanges

- SA182 F91 Alloy Steel Flanges

- ASTM A182 Alloy Steel F91 PN 10 Flange

- ASTM A182 Alloy Steel F91 Lapped Joint Flanges

- Chrome Moly A182 F91 Spectacle Blind Flanges

- Alloy Steel A182 F91 BS Standard Table E

- ASME SA182 F91 Flanges

- Alloy Steel A182 F91 British Standard Table D Pipe Flanges

- Alloy Steel 1.4903 1500 LBS Flanges

- ASME SA182 Alloy Steel F91 150 LBS Threaded Flanges

- ASTM A182 Cr-Mo F91 Nipo Flanges

- Chrome Molybdenum ASME SA182 Long Welding Neck Flange

- Cr-Mo A182 F91 Spades Ring Spacers Flanges

- Type ASME SA182 Alloy Steel F91 Industrial Forged Flanges

Weight Chart

15mm (1/2″) Alloy Steel A182 F91 Flanges Weight Chart

Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Pressure Rating

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Chemical Structure

| Grade | C | Mn | P | S | Si | Ni | Ch | Mo | Cb | N |

| F91 | 0.08-0.12 | 0.30-0.60 | 0.020 | 0.010 | 0.20-0.50 | 0.40 | 8.0-9.5 | 0.85-1.05 | 0.06-0.10 | 0.03-0.07 |

Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

|---|---|---|---|---|---|

| F91 | 585 | 415 | 20 | – | 248 max |

We Serve Application Industry

Application Industry

ANSI / ASME 16.5, 16.48, 16.47 Flanges applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Alloy Steel A182 F91 Flanges Across the Globe

Australia, Hungary, Japan, Belarus, Belgium, Venezuela, Oman, Norway, Russia, Kazakhstan, Lahore, Poland, Israel, Tunisia, Ghana, India, Lebanon, Austria, Slovakia, Algeria, Saudi Arabia, Turkey, Indonesia, Taiwan, Chile, Pakistan, Argentina, Afghanistan, Colombia, Canada, Serbia, Zimbabwe, United States, France, Brazil, Bolivia, Germany, Spain, United Arab Emirates, Libya, Algiera, columbia, Gabon, United Kingdom, Croatia, Peru, Trinidad & Tobago, Morocco, Malaysia, Kenya, Sweden, Iran, Ukraine, Philippines, Ecuador, Nigeria, Thailand, Mexico, Romania, South Korea, Bangladesh, Ireland, Nepal, Tibet, Portugal, Gambia, Estonia, Namibia, Bhutan, Netherlands, Iraq, Mongolia, Italy, Sri Lanka, Bahrain, Bulgaria, Greece, Qatar, Czech Republic, Macau, Azerbaijan, Angola, Vietnam, Switzerland, Egypt, Yemen, China, Jordan, New Zealand, Puerto Rico, Denmark, Costa Rica, Lithuania, Hong Kong, Finland, Kuwait, Singapore, South Africa.

Domestic Supply Alloy Steel A182 F91 Flanges

Pimpri-Chinchwad, Bhopal, New Delhi, Howrah, Noida, Visakhapatnam, Gurgaon, Bengaluru, Ernakulam , Kolkata, Jamshedpur, Pune, Chennai, Jaipur, Nashik, Faridabad, Rajkot, mumbai, Ludhiana, Ahmedabad, Thane, Secunderabad, Thiruvananthapuram, Nagpur, Haryana, Hyderabad, Indore, Chandigarh, Kanpur, Navi Mumbai, Ranchi, Surat.

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004