Titanium Pipe Fittings Manufacturer

Home / Titanium Pipe Fittings

Titanium pipe fittings are components used in piping systems made from strong & corrosion-resistant titanium. Titanium is known for its exceptional properties, high strength-to-weight ratio, excellent corrosion resistance & biocompatibility.

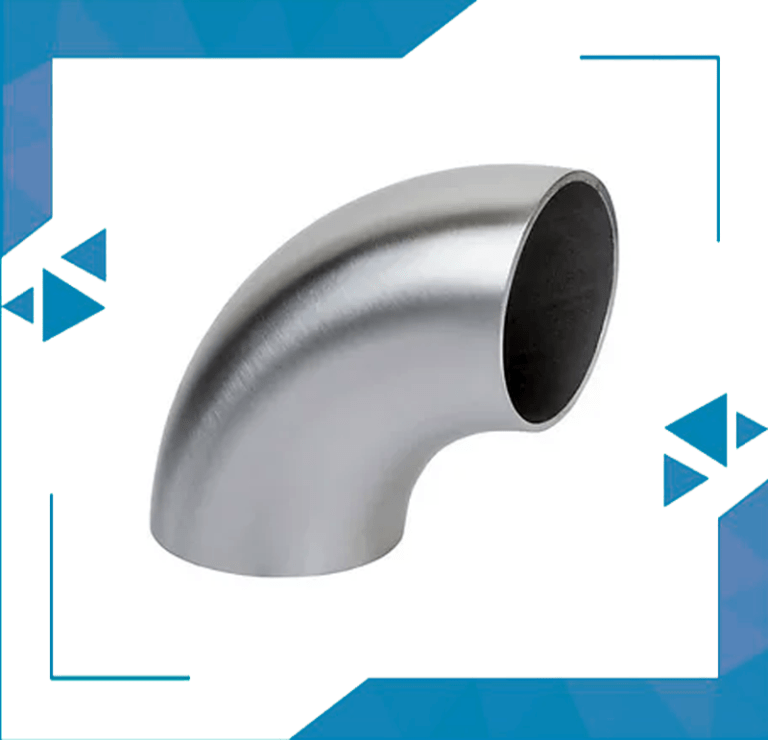

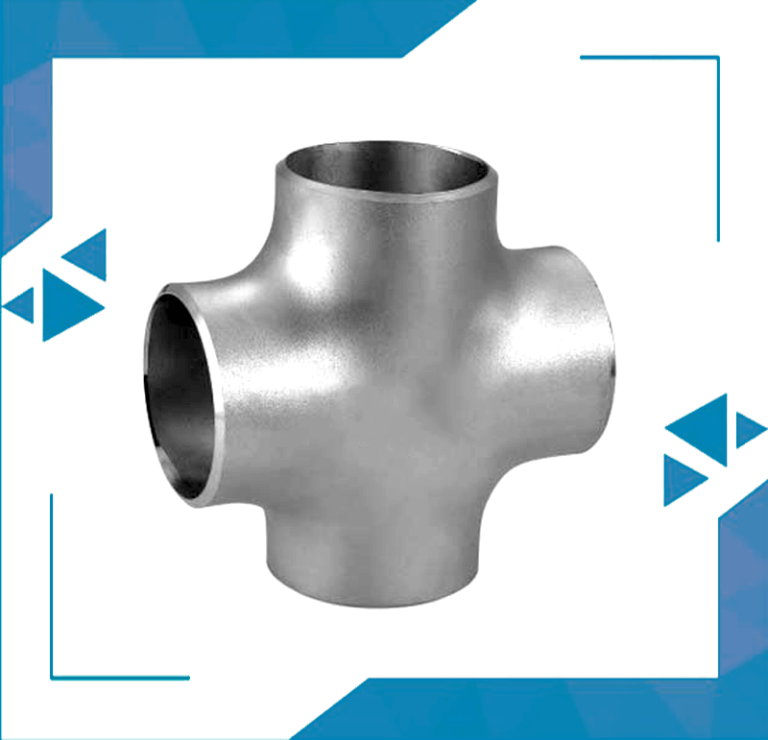

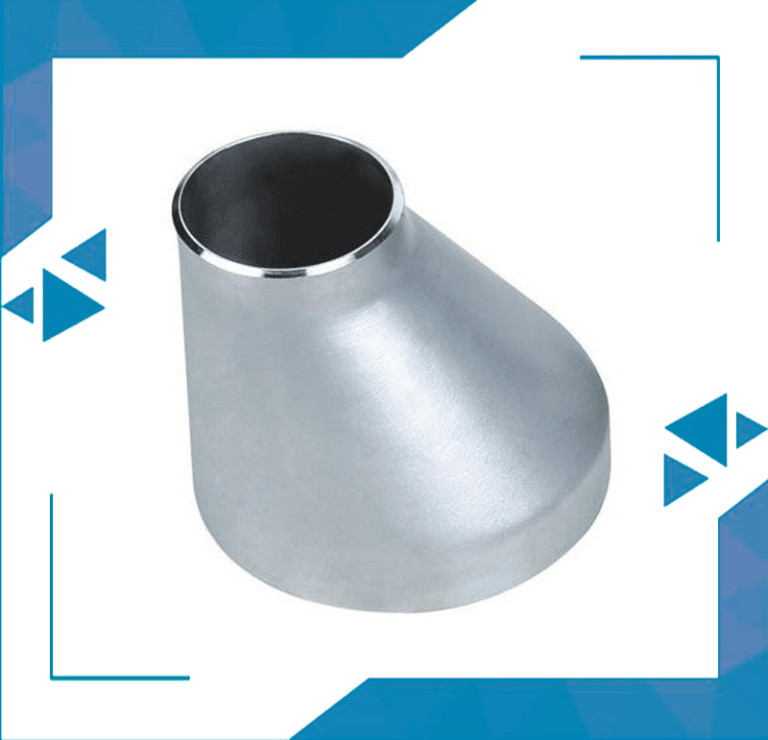

Titanium Pipe Fittings come in various shapes and configurations, including elbows, tees, reducers, couplings, and flanges. Using titanium pipe fittings offers several advantages due to the unique properties of titanium. One of the primary benefits is its exceptional corrosion resistance, which ensures the fittings can withstand corrosive environments without deteriorating over time. This corrosion resistance extends the lifespan of the fittings, reducing maintenance and replacement costs.

Table Of content

- About Titanium Pipe Fittings

- Specification List of Titanium Pipe Fittings

- Manufacturing Standards of ASTM B363 Titanium Pipe Fittings

- Different Types of Titanium Pipe Fittings

- Available Stock of Titanium Buttweld Pipe Fittings

- Titanium Pipe Fittings Dimensional Tolerances

- We Serve Application Industry

- We Export Titanium Pipe Fittings Across the Globe

- Domestic Supply Titanium Pipe Fittings

Titanium’s impressive strength-to-weight ratio contributes to the fittings’ durability while maintaining a lightweight construction. This characteristic is particularly valuable in applications where both strength and reduced weight are crucial, such as aerospace and marine industries.

Titanium Tube Fittings are biocompatibility, making them suitable for applications in the medical field, such as implantable medical devices & surgical instruments. This property also extends to pharmaceutical and food industries, where maintaining product purity is essential.

ASTM B363 Ti Pipe Fittings can handle a wide range of temperatures, from extreme cold to high heat, without losing their structural integrity. This capability enhances their suitability for diverse industrial settings. The high-quality titanium products we provide at Global Steel include Titanium Grade 2 Pipe Fittings, Titanium Grade 5 Pipe Fittings and more.

Titanium’s low thermal expansion minimizes the risk of dimensional changes in response to temperature fluctuations. This attribute ensures stability & reliability in various operating conditions. We provide an extensive range of products, such as Monel Olets, Stainless Steel 317 Flanges and more.

The longevity of Titanium Buttweld Pipe Fittings is a significant advantage. Their corrosion resistance and overall robustness ensure extended service life, reducing the need for frequent replacements & improving the overall cost-effectiveness of projects.

Using ASME B16.9 Pipe Fittings combines corrosion resistance, strength, biocompatibility, temperature resistance & longevity, making them a valuable choice for industries that demand reliable performance in challenging and diverse environments.

How are Titanium Pipe Fittings used in aerospace applications?

Titanium Pipe Fittings find use in aerospace applications due to their lightweight design, corrosion resistance, and compatibility with aerospace industry requirements.

What is the impact of titanium’s lightweight nature on pipe fitting installations?

Titanium’s lightweight nature can simplify installation processes, reducing the need for heavy lifting equipment. This advantage is particularly relevant in industries such as aerospace and marine where weight reduction is critical.

What is the role of Titanium Pipe Fittings in maintaining fluid purity?

Discover high-quality Titanium Pipe Fittings at Global Steel. Durable, versatile, and corrosion-resistant fittings for all industrial needs.

Specification of Titanium Pipe Fittings

| Standards | ASTM B363 / ASME S B363 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size |

|

| Type | Seamless / Welded / Fabricated |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

Manufacturing Standards

| ASME B16.9 ASTM B363 Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers |

Different Types

Titanium Pipe Elbow

Titanium Pipe Tee

Titanium Pipe Cross

Titanium Reducers

Titanium Pipe Cap

Titanium Stub End

Contact us to get a quick quote for your requirement.

We offer These Titanium Buttweld Pipe Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Titanium 45° Short Radius Elbow

- Titanium Titanium 2D Elbow

- Titanium 1D Elbow

- Titanium Alloy Lap Joint Stub Ends

- ASME B16.28 Titanium Alloy Two Joint Pipe Fittings

- Titanium Pipe Fittings

- Ti Alloy Buttweld Pipe Fittings

- Titanium Reducers

- ASTM B363 Titanium Lateral Tee

- ANSI B16.9 Titanium Pipe Caps

- Titanium Alloy Pipe Reducing Tee

- Type Titanium Industrial Buttweld Fittings

- Titanium Two Halve Butt weld Fittings

- Titanium Eccentric Reducer

- Ti Buttweld Elbow

- Titanium Alloy Buttweld Pipe Fittings

- Ti Alloy Pipe Bends

- Titanium Alloy Two Joint Pipe Fittings

- Titanium Buttweld Pipe Nipple

- Titanium Alloy Pipe Bends

- Titanium 45 Degree Pipe Elbow

- Titanium Alloy 180° Buttweld Elbow

- Titanium Concentric Reducer

- ANSI B16.28 Titanium Seamless Pipe Fittings

- Titanium Reducing Elbow

- Titanium Butt Weld Elbows 90°-SR- ASME B16.9

Dimensional Tolerances

| 1/2 TO 2-1/2 | +1/16 | ±1/32 | Not less than 87-1/2% of Normal Thickness | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 12 to 4 | 1/32 | 1/16 |

| -1/32 | 5 to 8 | 1/16 | 1/8 | |||||||||

| 3 TO 3-1/2 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 10 to 12 | 3/32 | 3/16 | |

| 4 | ±1/16 | ±1/16 | ±1/16 | ±1/16 | ±1/8 | ±1/4 | ±1/4 | ±1/32 | 14 to 16 | 3/32 | 1/4 | |

| 5 TO 8 | +1/32 | ±1/16 | ±1/16 | ±1/16 | ±1/4 | ±1/4 | ±1/4 | ±1/32 | 18 to 24 | 1/8 | 3/8 | |

| -1/16 | ||||||||||||

| 10 TO 18 | +1/16 | ±1/8 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | All dimensions are in inches | |||

| -1/8 | ||||||||||||

| 20 TO 24 | +1/4 | ±3/32 | ±3/32 | ±3/32 | ±1/4 | ±3/8 | ±1/4 | ±1/16 | ||||

| -3/32 | ||||||||||||

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004