Monoflange Manifold Valves Manufacturer

Home / IBR / Valves / Monoflange Manifold Valves

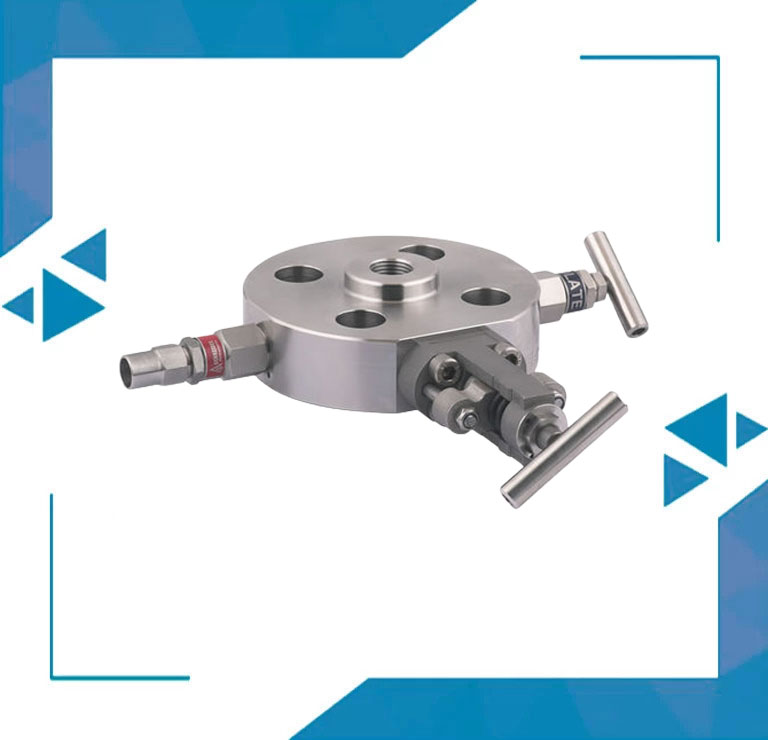

Global Steel is a significant producer and manufacturer of Monoflange Manifold Valves. We, the supplier of monoflange valves, prioritize designs that incorporate safety features that limit vibration and lower the total height of a gauge installation.

Table Of content

- About Monoflange Manifold Valves

- Specification List of Monoflange Manifold Valves

- Different Types of Monoflange Manifold Valves

- Available Stock of Monoflange Manifold Valves

- Monoflange Manifold Valves Pressure Rating

- Monoflange Manifold Valves Dimension Standards

- We Serve Application Industry

- We Export Monoflange Manifold Valves Across the Globe

- Domestic Supply Monoflange Manifold Valves

What are Monoflange Manifold Valves?

Monoflange manifold is employed as an alternative to multivalve systems. Despite additional equipment, makers of monoflange valves make sure the valves are mainly designed to contain gauge or transmitter devices with a compact installation. For example, two valves are utilized to isolate a transmitter rather than just one valve depending on it to close. A double block and bleed mono flange can be used in place of the two valves. It eliminates the requirement for two valves and consolidates everything into one.

A vent is opened to lessen the pressure between the two closed valves on the mono flange. It offers a more reliable gadget because of its reduced weight and leak pathways. The danger of harm from vibration is further decreased by the shorter installation time.

Maintaining the gauge erect is simpler when Monoflange Manifolds are mounted directly on vertically or horizontally oriented flange connections. Both primary isolation (double block and bleed) and instrument (block and bleed) responsibilities are appropriate for monoflanges. In a single, portable device, monoflange offers isolation, ventilation, and instrument mounting.

What occurs after a Monoflange Manifold valve is inserted inside?

Most control applications in a chemical reaction demand a fast response time. The volume and distance between the process and the instruments are two factors that influence response time. Mounting the device close to the process is the answer if the gas being monitored is the medium, the technique occasionally fluctuates dramatically, or the control is crucial.

The monoflange design contains safety elements that lower the gauge installation’s overall height and aid in decreasing vibration. Vibrations are also essential in other situations, such as when impulse lines are attached to a vessel. The amount of vibration that might lead to the nozzle failing increases with the length of the hook-up. A monoflange allows for a substantial decrease in volume, dimensions, weight, and possible leakage points by housing one, two, or three needle valves inside a small, flange-shaped body.

What is a monoflange manifold valve?

Monoflange manifold valves are a key component of any hydraulic system. They are usually composed of two primary pieces: the contact flange and the circular main body, which make it possible to control several sections of pipe in the same area. Monoflange manifold valves have the advantage of helping to reduce leak points and maintenance costs due to their simplicity compared with more traditional valves. In addition, they offer superior performance under high pressure and temperature conditions. As such, they can be excellent options when used as part of an effective piping system solution in complex industrial environments.

How are monoflange manifold valves installed?

Monoflange manifold valves are an important element of many industrial systems. Installing these vital components requires precise technique and skill, as a proper installation ensures precise flow control and improved operational safety. After the receiver or vessel is connected to the valve inlet, technicians Bolt the flange connections together, adhere to torque sequences and needle-screws settings provided by manufacturers’ specifications, and attach lines according to their purpose. It is also common practice to configure a bleed connection between the two manifold sizes – the larger one feeding down into the smaller one – in order to eliminate pressure later on. With these measures taken into consideration during installation, monoflange manifolds can be used securely for years of accurate operations and successful flow control regulation.

What materials are monoflange manifold valves made of?

Monoflange manifold valves are typically made of a range of materials including stainless steel, brass, and carbon steel. Manufacturers use these materials due to their strength and durability, as they must be able to withstand extreme temperatures and high pressure without corroding or cracking. Special coatings can also be applied to the surface of the valve material to improve sealed performance and resistance to extreme environments. It is important for users to ensure that the monoflange manifold valve material can handle chemical compatibility with any liquids flowing through it.

Specification of Monoflange Manifold Valves

| MOC | SS 316, SS 304, SS 316 TI, COPPER, BRASS, DUPLEX, CS, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L, TITANIUM & ALL OTHER ALLOYS |

| SIZES | 1/2″ NB TO 2″ NB |

| FUNCTION | 2 WAY, 3 WAY, 5 WAY |

| BODY SHAPE | SQUARE, RECTANGLE |

| WORKING PRESSURE | VALVES ARE ALSO AVAILABLE WHICH COULD HANDLE HIGHER PRESSURE, UP TO 6000 PSIG |

| END CONNECTION | NPT, BSP, BSPT, SW, METRIC. |

| TEMPERATURE RATINGS | (232C)/GRAFOIL 700 F(371C), PTFE 450F |

| PRESSURE RATING | 150#, 300#, 600#, 900#, 1500#, 2500# |

| APPLICATION | SAMPLING SYSTEMS, PRESSURE INSTRUMENT TAKE OFF POINTS, PRIMARY ROCESS ISOLATION VALVE, FLUSHING CONNECTIONS CHEMICAL INJECTION SYSTEMS, HEMICAL SEAL PLICATIONS DRAINS FOR TANKS AND PIPES WHERE SPACE IS LIMITED, VENT & PURGE APPLICATIONS. |

| ENDS | FLANGE ENDS, SCREWED ENDS,SOCKET WELD ENDS |

| TYPE | BAR STOCK, FORGED |

| TEMPERATURE RATING | (232C)/GRAFOIL 700 F(371C),PTFE 450F |

Different Types

MONOFLANGE MANIFOLD VALVES

SINGLE BLOCK & BLEED TYPE

MONOFLANGE SINGLE ISOLATION

DOUBLE BLOCK & BLEED

MONOFLANGE BLOCK & BLEED

MONOFLANGE VALVES

Contact us to get a quick quote for your requirement.

We offer These Stainless Steel Monoflange Manifold Valves as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- Stainless Steel 316L Monoflange Manifold Valves

- High Pressure Monoflange Manifold Valve

- Monoflange Manifolds

- SDSS Monoflange Manifold Valves

- Single Block & Bleed Type Monoflange Manifold Valve

- Monoflange Single Isolation

- Monoflange Block & Bleed Valves

- Super Duplex Steel Monoflange Manifold Valves

- Duplex Stainless Steel 316L Monoflange Manifold Valve

- SS 304 Monoflange Manifold Valves

- Stainless Steel 6000 Psi MonoflangValves

- Duplex Steel 3000 PSI Monoflange Manifold Valves

- 15000 PSI Monoflange Manifold Valves

- Carbon Steel Two Way Monoflange Manifold Valve

- Titanium Gr 2 Monoflange Manifold Valves

- Monoflange Single Block and Bleed Valves

- Inconel Monoflange Manifold Valve

- 20000 PSI Monoflange Manifold Valves

- Double Block and Bleed Monoflange Manifold

- SS 316 Monoflange Manifold Valve

- Alloy 20 Monoflange Manifold Valves

- 10000 PSI Monoflange Manifold Valves

- 316 Stainless Steel Monoflange Manifold Valves

- Nickel Alloy Monoflange Manifold Valve

- Instrumentation Monoflange Manifold Valve

Equivalent Material Grade

DESCRIPTION |

BARSTOCK |

FORGING |

UNS GRADE |

CASTING |

|---|---|---|---|---|

Carbon Steel |

A105 |

A105 |

K30504 |

A216 WCB |

Low Temp Carbon |

A350 LF2 |

A350 LF2 |

K03011 |

A352 LCB |

High Yield Steel |

A694 F60 |

A694 F60 |

K03014 |

– |

3 1/2 Nickel Steel |

A350 LF3 |

A350 LF3 |

K32025 |

A352 LC3 |

5 Chrome, 1/2 Moly |

A182 F5 |

A182 F5 |

K41545 |

A217 C5 |

1 1/4 Chrome, 1/2 Moly |

A182 F11 |

A182 F11 |

K11597 |

A217 WC6 |

2 1/4 Chrome, 1 Moly |

A182 F22 |

A182 F22 |

K21590 |

A217 WC9 |

9 Chrome, 1 Moly |

A182 F9 |

A182 F9 |

K90941 |

A217 WC6 |

13 Chrome |

A276 or A479 410 |

A182 F6A |

S41000 |

A351 CA15 |

304 |

A276 or A479 304 |

A182 F304 |

S30400 |

A351 CF8 |

304L |

A276 or A479 304L |

A182 F304L |

S30403 |

A351 CF3 |

316 |

A276 or A479 316 |

A182 F316 |

S31600 |

A351 CF8M |

316L |

A276 or A479 316L |

A182 F316L |

S31603 |

A351 CF3M |

317L |

A276 or A479 317L |

A182 F317L |

S31703 |

A351 CG8M |

321 |

A276 or A479 321 |

A182 F321 |

S32100 |

– |

347 |

A276 or A479 347 |

A182 F347 |

S34700 |

A351 CF8C |

17-4PH |

– |

A564 630 |

S17400 |

– |

Alloy 400 |

B164 N04400 |

B564 N04400 |

N04400 |

A494 M35-1 |

Alloy K500 |

B865 N05500 |

– |

N05500 |

– |

Alloy 800 |

B408 N08800 |

B564 N08810 |

N08800 |

– |

Alloy 825 |

B425 N08825 |

– |

N08825 |

– |

Alloy 600 |

B166 N06600 |

B564 N06600 |

N06600 |

A494 CY40 |

Alloy 625 |

B446 N06625 |

B564 N06625 |

N06625 |

A494 CW 6MC |

Alloy B2 |

B335 N10665 |

B564 N10665 |

N10665 |

A494 N 12MV |

Alloy C |

– |

– |

N10002 |

A494 CW6M |

Alloy C22 |

B574 N06022 |

B574 N06022 |

N06022 |

A494 CX2MW |

Alloy C276 |

B574 N10276 |

B564 N10276 |

N10276 |

A494 CW12 MW |

22% Duplex |

A276 or A479 S31803 |

A182 F51 |

S31803 |

A890 Gr 4A |

25% Duplex |

A276 or A479 S32750 or 60 |

A182 F53 |

S32750 or 32760 |

A890 Gr 6A |

254SMO |

A182 F44 |

A182 F44 |

S31254 |

A351 CK3MCuN |

904L |

B649 N08904 |

B625 N08904 |

N08904 |

– |

Titanium |

B348 Gr 2 |

B381 F2 |

R50400 |

B367 C2 |

Dimensions

| SIZE (inch.) |

A (mm) |

RATING (lb.) |

ØB (mm.) |

| 1/2″ | 57 | 150 | 89 |

| 1/2″ | 57 | 300 | 96 |

| 1/2″ | 61 | 600 | 96 |

| 1/2″ | 64 | 900 | 121 |

| 1/2″ | 64 | 1500 | 121 |

| 1/2″ | 64 | 2500 | 134 |

| 3/4″ | 57 | 150 | 99 |

| 3/4″ | 60 | 300 | 118 |

| 3/4″ | 64 | 600 | 118 |

| 3/4″ | 64 | 900 | 130 |

| 3/4″ | 64 | 1500 | 130 |

| 3/4″ | 64 | 2500 | 140 |

| 1″ | 57 | 150 | 108 |

| 1″ | 60 | 300 | 124 |

| 1″ | 64 | 600 | 124 |

| 1″ | 67 | 900 | 150 |

| 1″ | 67 | 1500 | 150 |

| 1″ | 67 | 2500 | 159 |

| 1 1/2″ | 60 | 150 | 127 |

| 1 1/2″ | 63 | 300 | 156 |

| 1 1/2″ | 67 | 600 | 156 |

| 1 1/2″ | 67 | 900 | 178 |

| 1 1/2″ | 67 | 1500 | 178 |

| 1 1/2″ | 72 | 2500 | 203 |

| 2″ | 63 | 150 | 153 |

| 2″ | 63 | 300 | 165 |

| 2″ | 67 | 600 | 165 |

| 2″ | 72 | 900 | 216 |

| 2″ | 72 | 1500 | 216 |

| 2″ | 73 | 2500 | 235 |

We Serve Application Industry

Application Industry

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Monoflange Manifold Valves Across the Globe

Domestic Supply Monoflange Manifold Valves

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004