Titanium Forged Fittings Manufacturer

Home / Titanium Forged Fittings

Global Steel is an established manufacturer and supplier of titanium forged fittings. All our products undergo a strict quality check process to ensure no discrepancies.

Table Of content

- About Titanium Forged Fittings

- Specification List of Titanium Forged Fittings

- Manufacturing Standards of ASTM B381 Titanium Forged Fittings

- Different Types of Titanium Forged Fittings

- Available Stock of Titanium Socketweld Forged Fittings

- We Serve Application Industry

- We Export Titanium Forged Fittings Across the Globe

- Domestic Supply Titanium Forged Fittings

Titanium forged fittings are made of titanium which is a structural material that is resistant to several types of corrosion. Titanium forged fittings have a lot of strength but are extremely light. The chemical and mechanical qualities of Titanium Pipe Fittings are good. They’re also constructed with high tensile strength and good dimensional correctness. Titanium forged fittings possess high hardness and anti-corrosive characteristics.

Titanium forged fittings are resistant to pitting, stress relation corrosion cracking, general corrosion, and crevice corrosion. They’re also resistant to oxidizing conditions. All of these characteristics make titanium forged fittings an excellent choice for use in a variety of essential industrial applications. They have a long service life and are capable of handling a wide range of complex industrial applications with ease. They’re employed in water treatment plants, power generating, marine chemical processing, and desalination plants, among other things.

One of the best features of titanium forged fittings is that it has a similar high strength to stainless steel but is roughly 40% lighter. Titanium forged fittings have a good tensile strength to density ratio as well. They can withstand a wide range of chemical media with ease. They have a low elasticity modulus, making them extremely flexible. It means that even after being bent, they can return to their former shape. Titanium forged fittings have high boiling and melting temperatures due to their metallic characteristics.

How are Titanium Forged Fittings made?

Titanium Forged Fittings are made by heating the titanium to a high temperature, typically between 900°C and 1200°C, and then shaping it using a hammer or press. The fittings are machined to the required size and shape and undergo quality control testing before being sold. The forging process helps to increase the strength and durability of the fittings, making them ideal for use in demanding industrial applications.

What is the cost of Titanium Forged Fittings?

The cost of Titanium Forged Fittings can vary depending on several factors, including the size, shape, and quantity of fittings required and the supplier. Additionally, the cost of titanium as a raw material is generally higher than other metals, which can contribute to the overall cost. As a result, titanium fittings are typically more expensive than other materials, but they offer excellent performance in harsh environments and are often worth the investment.

What are the uses of titanium forged fittings?

Titanium Forged Fittings are used in various industrial applications, particularly in the chemical, petrochemical, and oil and gas industries. They are often used in harsh environments like offshore drilling rigs and pipelines, where corrosion resistance is critical. Other common uses include heat exchangers, pressure vessels, and seawater desalination plants. The high strength, low density, and excellent corrosion resistance of titanium make it an ideal material for use in demanding industrial applications.

Specification of Titanium Forged Fittings

| Standards | ASTM B381/ ASME SB381 |

| Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Forged Fittings Thread | NPT, BSPT, BSPP |

| Forged Fittings Test Certificates |

|

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

Manufacturing Standards

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Titanium Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel Forged fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged fittings socket-weld and threaded. Socket Weld and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Titanium fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Different Types

Titanium Forged Elbow

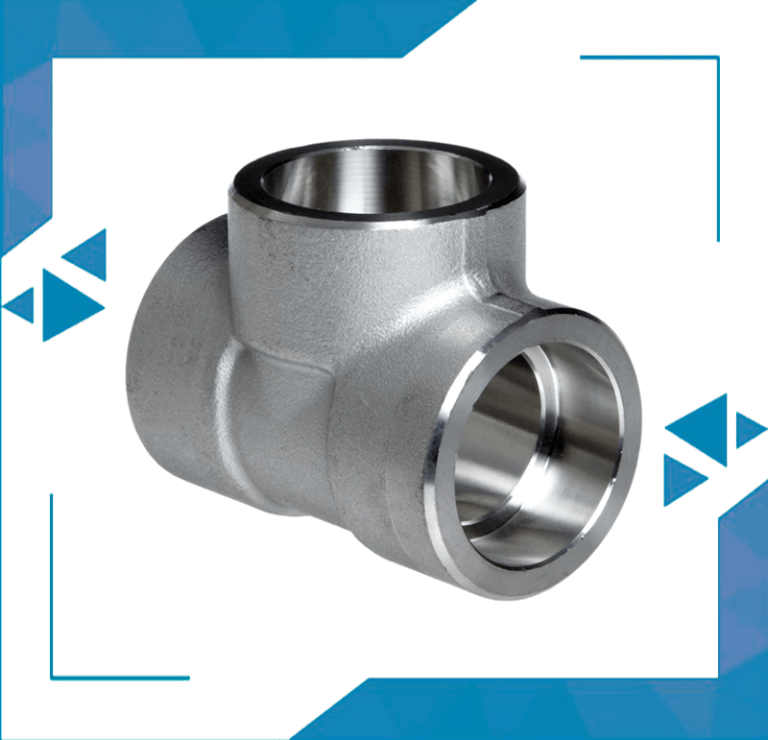

Titanium Forged Tee

Titanium Forged Cross

Titanium Coupling

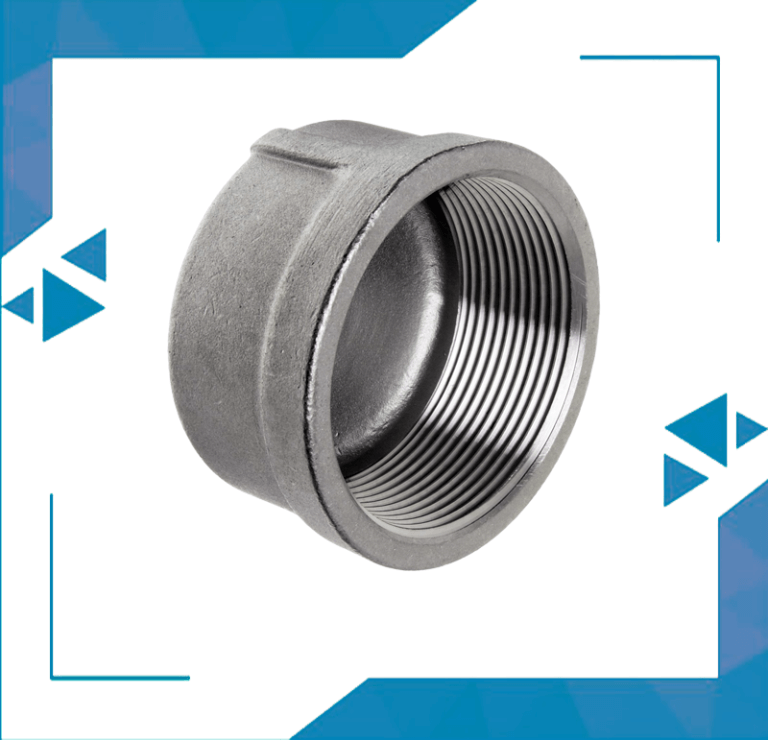

Titanium Forged Cap

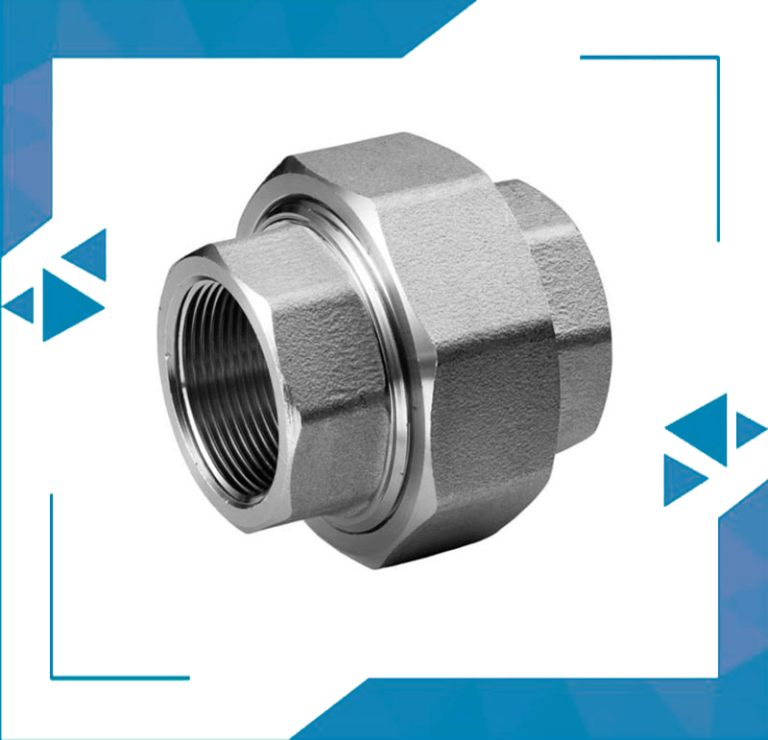

Titanium Union

Contact us to get a quick quote for your requirement.

We offer These Titanium Socketweld Forged Fittings as per DIN, ISO, JIS or ANSI Standard.

Available Stock

- ANSI B16.11 Titanium Forged Caps

- Titanium High Pressure Forged Pipe Fittings

- Titanium 45° Socket Weld Elbow

- Ti Alloy Forged Fittings

- Titanium Forged Fittings

- Titanium Hex Head Bushings

- Titanium Forged Reducing Tee

- Titanium Threaded Round Head Plugs

- Titanium Hex Head Plug

- ASME B16.11 Titanium Alloy Forged Pipe Fittings

- ASTM B381 Titanium Bushings

- Type Titanium Industrial Socketweld Fittings

- Titanium 3000 LBS Threaded Fittings

- Titanium Half Couplings

- Titanium Socketweld Forged Fittings

- Titanium Full Couplings

- Titanium 3000 LBS Socket Weld Fittings

- Titanium Reducing Insert

- Titanium Forged Street Elbow

- Titanium AlloyForged Pipe Fittings

- Titanium ANSI/ ASME B16.11 Socketweld Fittings

- Titanium Socketweld Forged Nipple

- Titanium Screwed Fittings

- Titanium Socketweld Forged Fittings

We Serve Application Industry

Application Industry

Socket weld Forged Fittings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil & Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Industry

We Export Titanium Forged Fittings Across the Globe

Domestic Supply Titanium Forged Fittings

Materials

Contact Us For Help?

Contact us at the Industrial nearest to you or submit a business inquiry online.

Global Steel is a significant manufacturer and exporter of all ferrous and non-ferrous metals. As a pioneer and leader in the industry, Global Steel is at the forefront of technology and research.

Quick Contact

Shop No.6, Sonarika Bldg, 25/C, Chandawadi, Cawasji Patel Tank, Mumbai, Maharashtra 400004